Grape vine rope cutting machine

A cutting machine and vine technology, applied in metal processing and other directions, can solve the problems of time-consuming and labor-consuming, reduce labor efficiency, etc., achieve the effect of fast winding speed, improve work efficiency and enterprise service quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

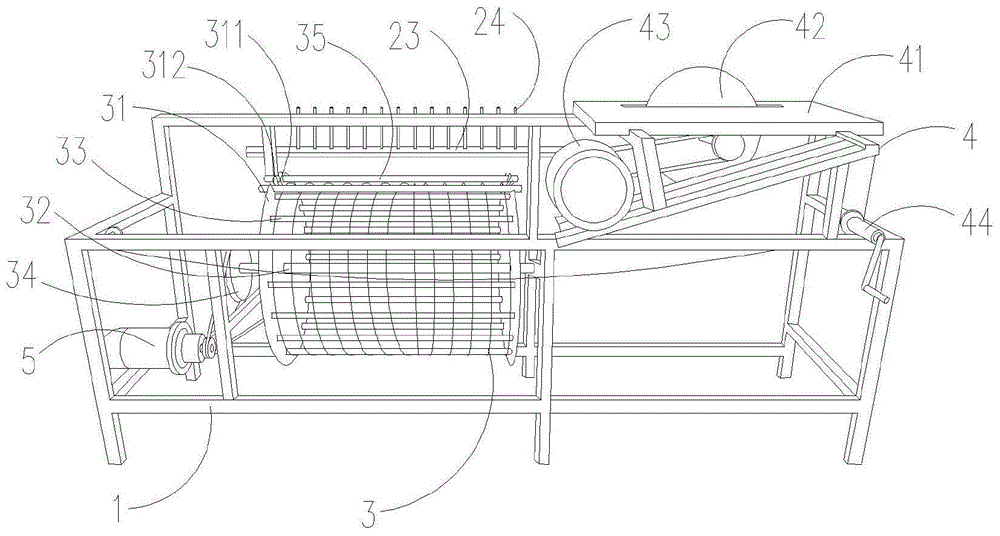

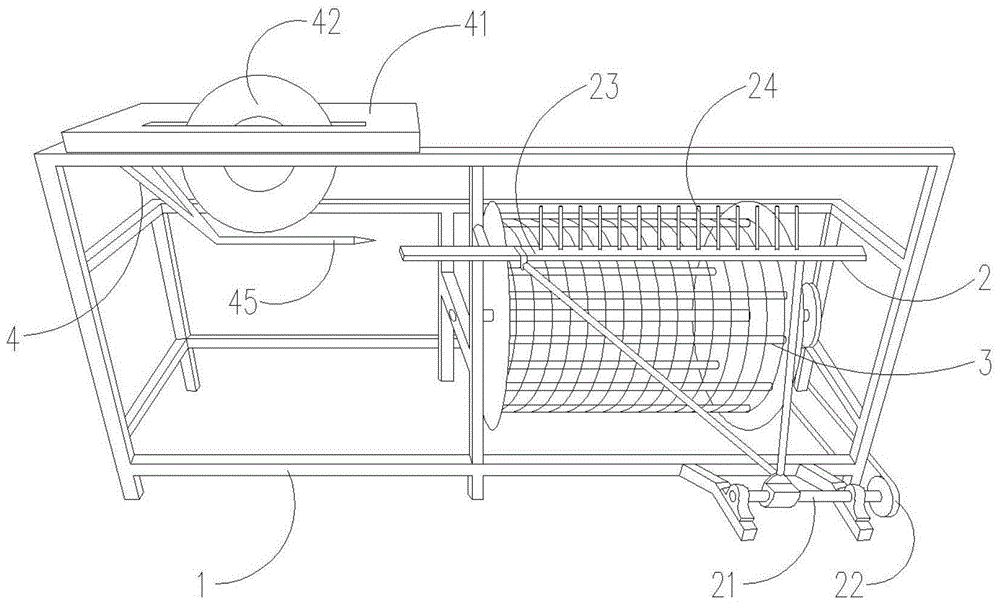

[0025] The rope cutting machine for tying vines of the present invention completes the cutting of the rope through the following steps:

[0026] For the rope winding operation, adjust the support rod 33 on the rope winding device 3 so that the perimeter of the cage reaches the required length. On the rod 24, the respective rope heads are respectively fixed on the support rod 33 of the rope winding device 3 in order; the power device 5 is started, and the swing rope frame 23 and the rope winding frame 23 of the swing rope device 2 are driven by the transmission wheel 22 and the rotating wheel 34 respectively. The device 3 works, and along with the rotation of the rope winding device 3, the rope on the rope winding spindle is wound on the cage frame of the rope winding device 3, and the swing rope frame 23 swings back and forth laterally along the swing rope shaft 21, so that the rope is evenly wound. On the cage frame of rope winding device 3.

[0027] For cutting operation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com