Aluminum part cutting device with positioning device

A cutting device and positioning device technology, applied in positioning devices, metal processing machinery parts, clamping and other directions, can solve the problems of poor batch operability, poor positioning, low efficiency, etc., and achieve controllable cutting length, good practicability, and clamping. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

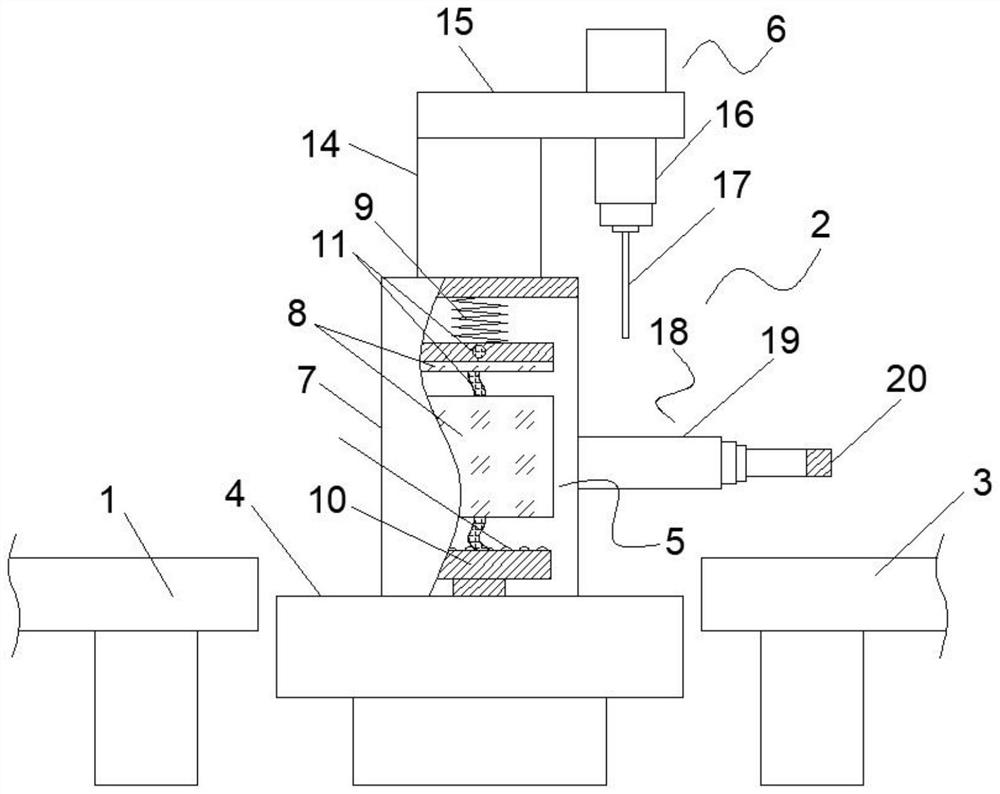

[0019] A cutting device for aluminum parts with a positioning device, including a feeding mechanism 1, a cutting mechanism 2, and a discharging mechanism 3 arranged in sequence. The feeding mechanism 1 and the discharging mechanism 3 adopt conveyor belts, which are driven by a motor to transfer aluminum parts. , the conveyor belt structure is an existing mature method, which is not limited here.

[0020] The height of the further horizontal surface of the conveyor belt is consistent with the height of the upper surface of the transmission plate on the operating table of the cutting mechanism (the height of the top of the ball), so as to facilitate the horizontal transmission of aluminum parts.

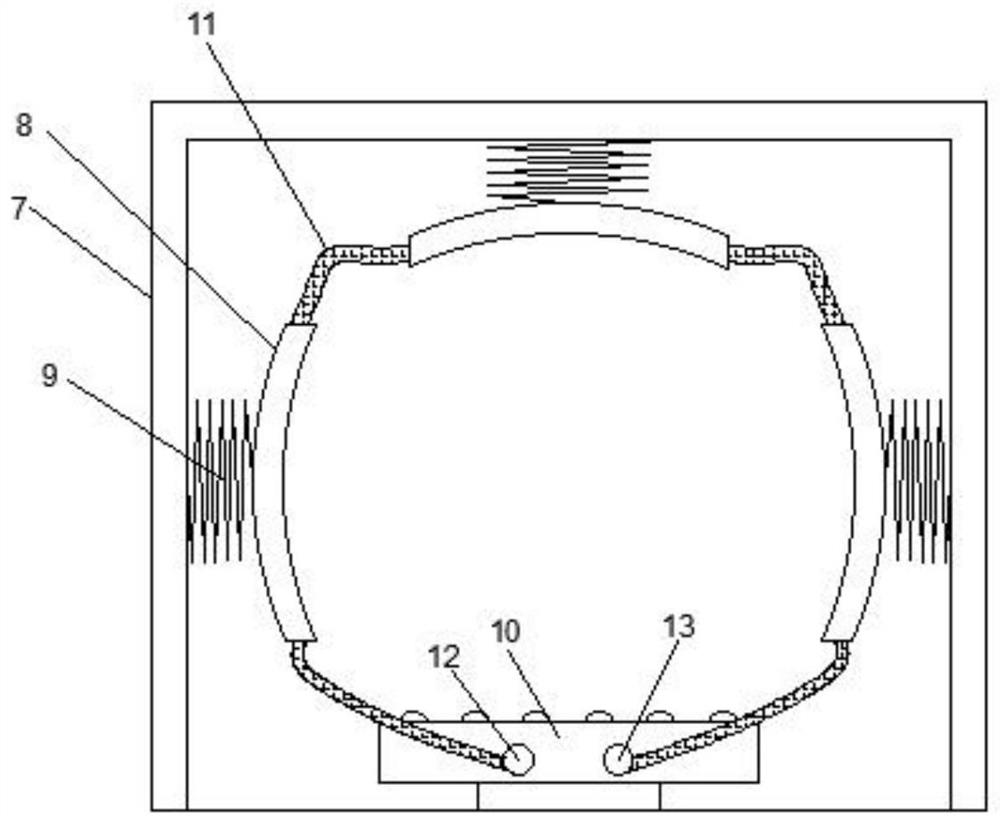

[0021] The cutting mechanism 2 includes an operation table 4, a clamping unit 5, and a cutting unit 6. The clamping unit 5 includes a clamping frame 7, a clamping plate 8 arranged in the clamping frame 7, the clamping plate 8 and the inner wall of the clamping frame 7 They are connecte...

Embodiment 2

[0030] A positioning unit 18 is also provided, and the positioning unit 18 includes two telescopic horizontal bars 19 (sleeve / inner rod structure with multi-stage gap sockets) symmetrically fixed on the side wall of the vertical section of the clamping frame 7, and the two telescopic horizontal bars A collision plate 20 is connected between the rods 19 for contacting with one end of the aluminum piece, and a rubber layer is also provided on the wall surface where the collision plate 20 contacts the aluminum piece.

[0031] Furthermore, the outer wall of the telescopic cross bar 19 is provided with a scale line (not shown in the figure) for observing the telescopic length of the telescopic cross bar, and the zero scale value of the scale line coincides with the vertical line in the extension direction of the cutting knife, that is, the cutting knife cuts The position of the zero scale line is the position of the zero scale line. When in use, the length of the cutting section can...

Embodiment 3

[0035] A mounting plate is installed at the bottom of the hydraulically driven telescopic column, and the cutting knife is connected to it through a rotating shaft of a high-precision multi-axis machine tool. When in use, the cutting direction is rotated through the rotating shaft, and at the same time, it can operate with multiple degrees of freedom (X / Y / Z Axial adjustment), to complete the cutting adjustment of aluminum parts in different directions, with strong cutting diversity and wide application range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com