Injection molding machine, control unit, and cooling unit

A technology for injection molding machines and cooling units, which is applied in the field of control panels, cooling units, and injection molding machines, and can solve problems such as unstable movements of the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

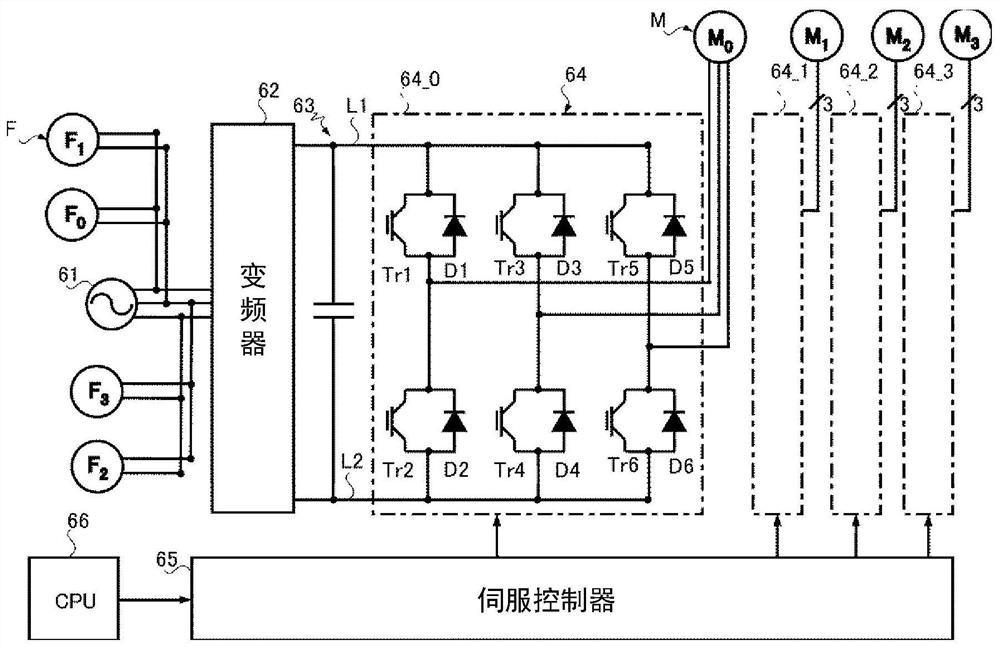

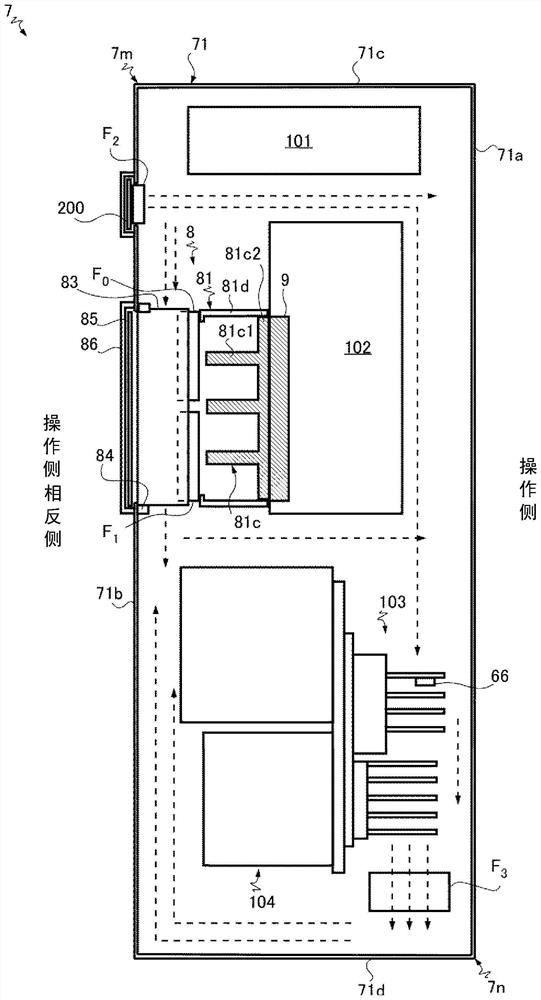

[0032] Below, refer to Figure 1 to Figure 5 Non-limiting embodiments and features of the present invention will be described. Those skilled in the art can combine the various embodiments and / or individual features without too much explanation, and can also understand the synergistic effect based on the combination. In principle, overlapping descriptions between the embodiments are omitted. The accompanying drawings are for the main purpose of describing the invention and have been simplified for ease of drawing. Each feature is not only valid for the injection molding machine disclosed in this specification, but can also be understood as a general feature that can be commonly used in various other injection molding machines not disclosed in this specification.

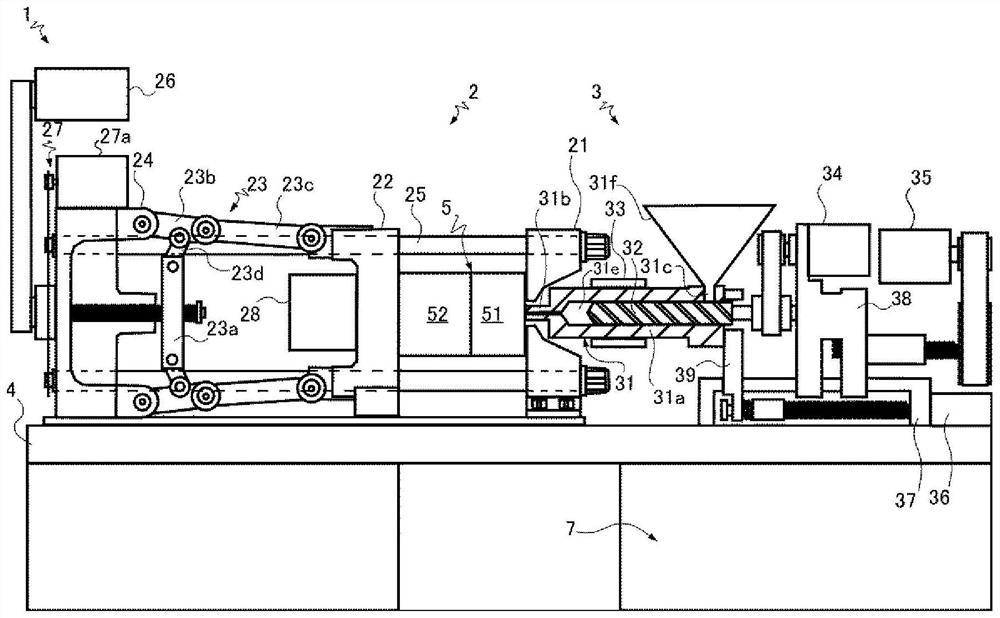

[0033] Such as figure 1 As shown, the injection molding machine 1 has a mold clamping device 2 and an injection device 3 mounted on a common or different base 4 . The injection molding machine 1 continuously manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com