Edge strip slender composite material airfoil and forming method thereof

A composite material and molding method technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of low material utilization, high density, easy deformation during processing, etc., and achieve improved interlayer performance and high fiber volume content , Good molding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that, for those skilled in the art, several changes and improvements can be made without departing from the inventive concept. These all belong to the protection scope of the present invention.

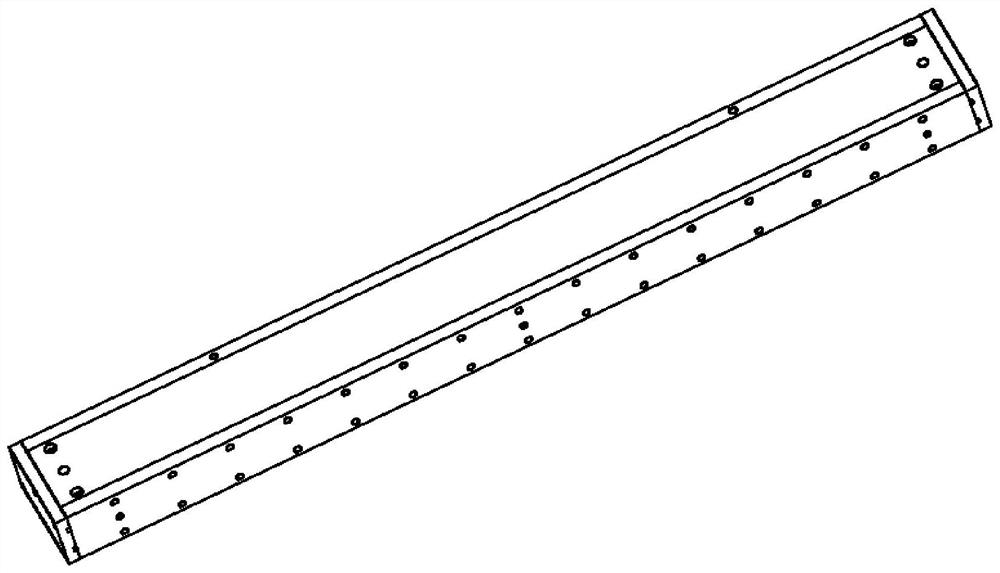

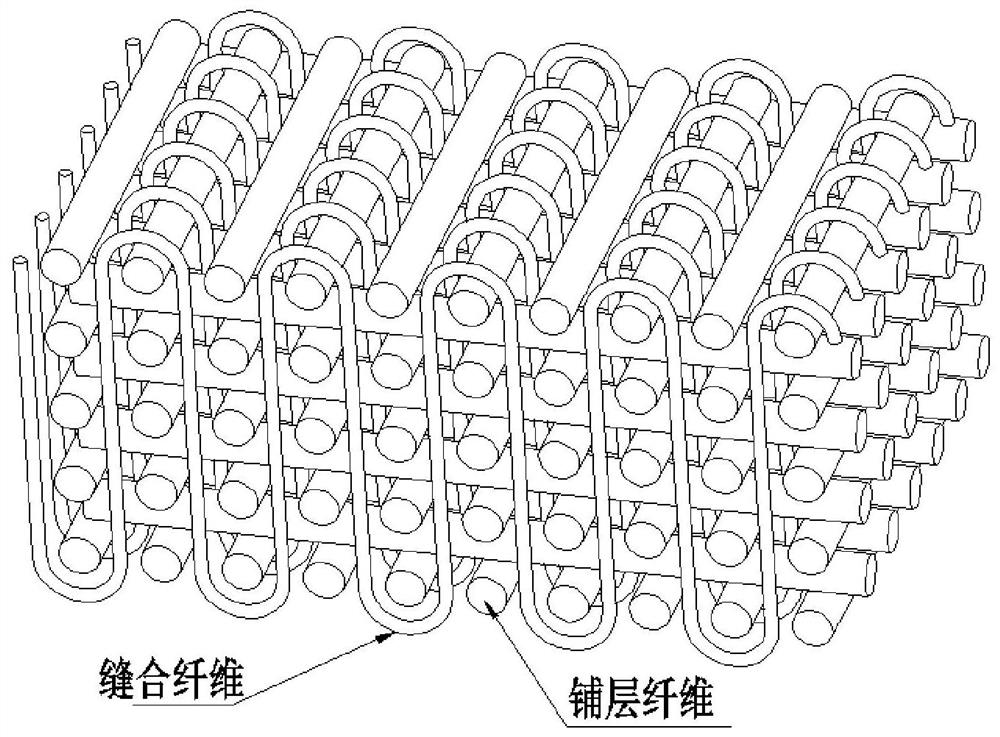

[0021] According to the molding method of the slender composite material airfoil provided by the present invention, the airfoil is subjected to Z-direction stitching and toughening after the carbon fiber UD cloth is laid, and a prefabricated reinforcement is injected with resin based on an autoclave and cured. The autoclave / VARTM combination process molding.

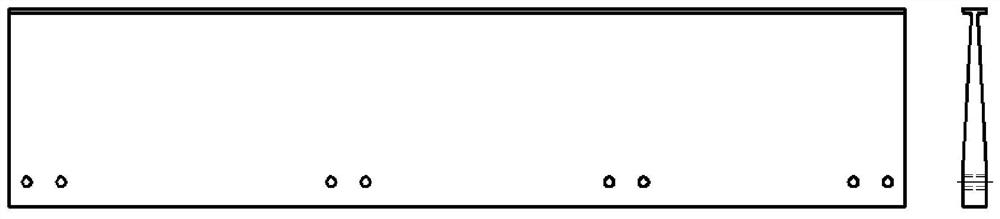

[0022] Preferably, the airfoil is integrally formed by integral lamination, and the thickness and shape of the airfoil are ensured by a mold, and seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com