EPE foam packaging material structure and manufacturing method thereof

A technology of packaging materials and mounting boards, which is applied in transportation and packaging, devices for coating liquid on the surface, and containers for preventing mechanical damage. The risk of damage to small goods, the improvement of distribution uniformity, and the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

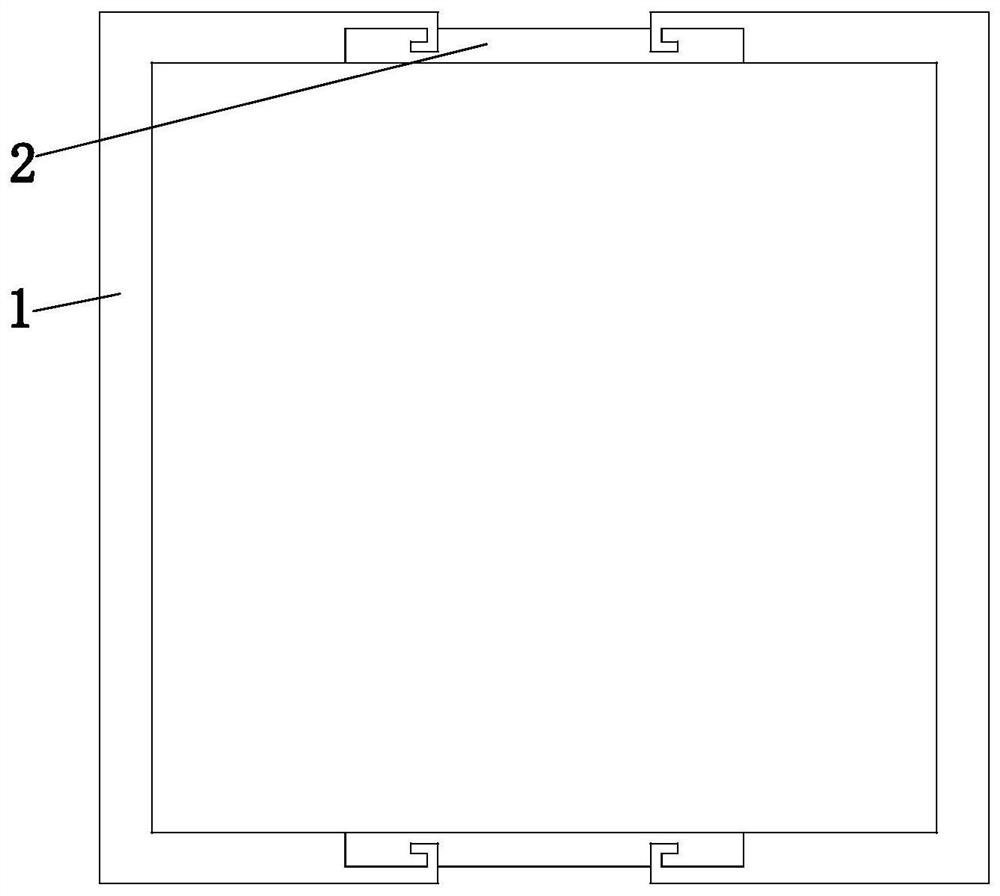

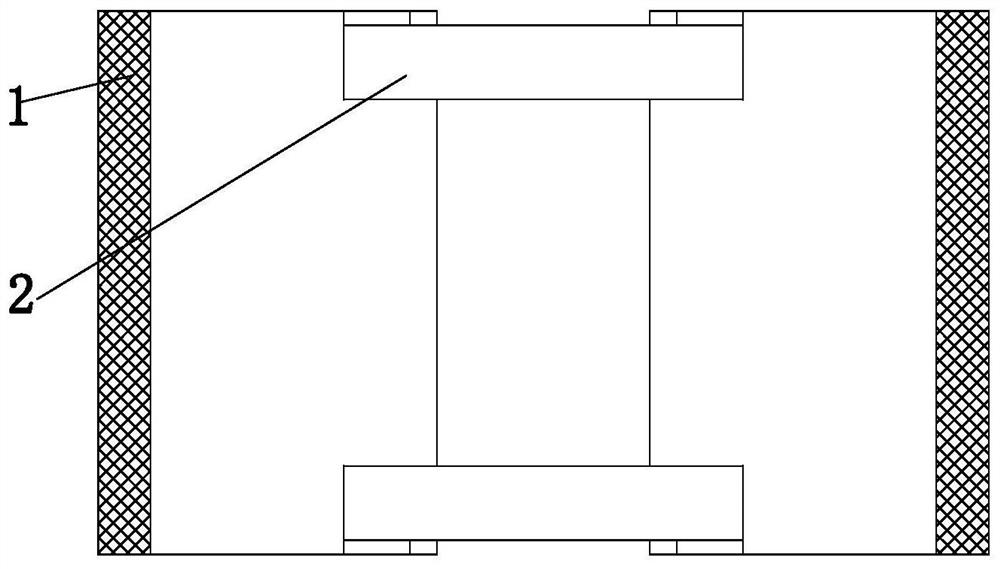

[0035] Such as Figure 1 to Figure 8 As shown, an EPE foam packaging material structure includes a main body 1 and a connecting strip 2. The main body 1 is a U-shaped structure, and the number of the main body 1 is two. There are connecting grooves symmetrically arranged up and down, and connecting strips 2 are clamped between the two connecting grooves arranged oppositely on the left and right. L-shaped locking grooves are symmetrically opened on the left and right sides of the connecting strip 2, and the shape of the connecting groove matches the shape of the L-shaped locking groove;

[0036] The above-mentioned EPE foam packaging material structure requires the use of special manufacturing machinery during production. The manufacturing machinery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com