Beam and column friction energy dissipation joint for laminated wood structure

A friction energy dissipation, wood structure technology, applied in building components, building structure, earthquake-proof and other directions, can solve the problem of low transverse grain tensile strength, brittle transverse grain splitting damage, underutilized mechanical performance, etc. problems, to achieve the effect of reducing the tensile effect of the horizontal stripes, improving the deformation capacity, good energy dissipation capacity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

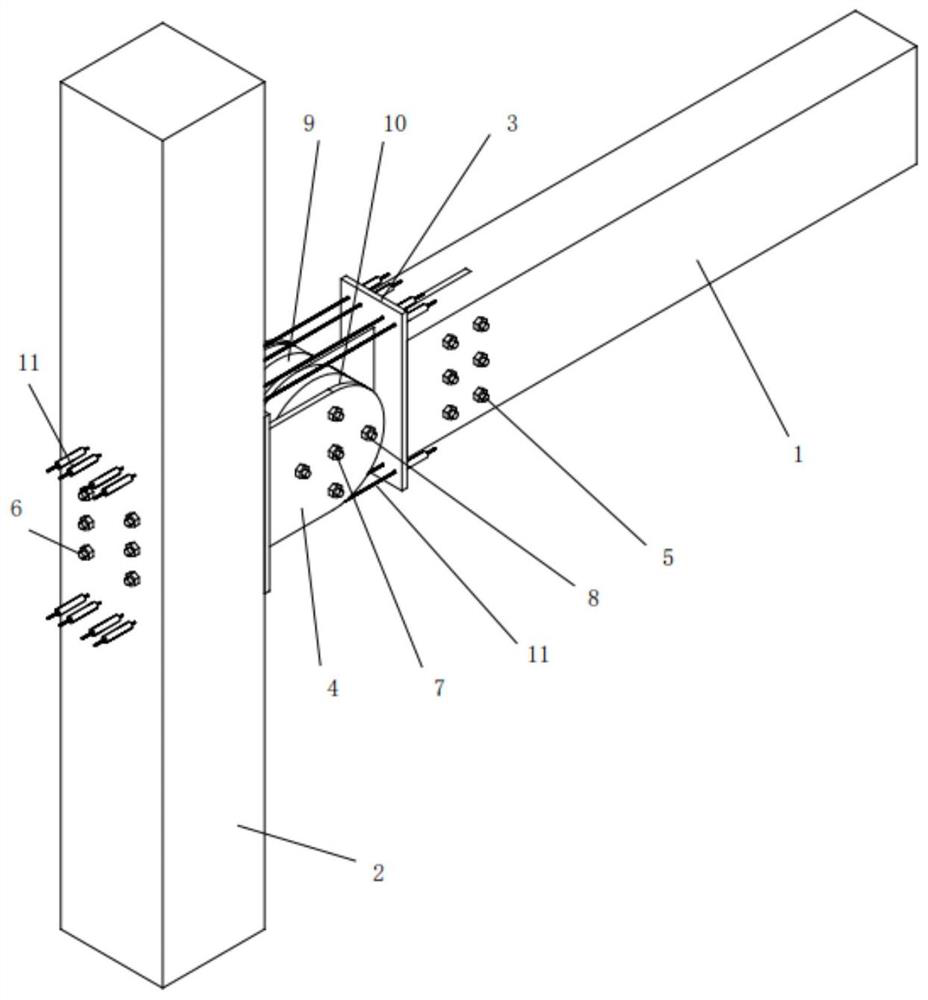

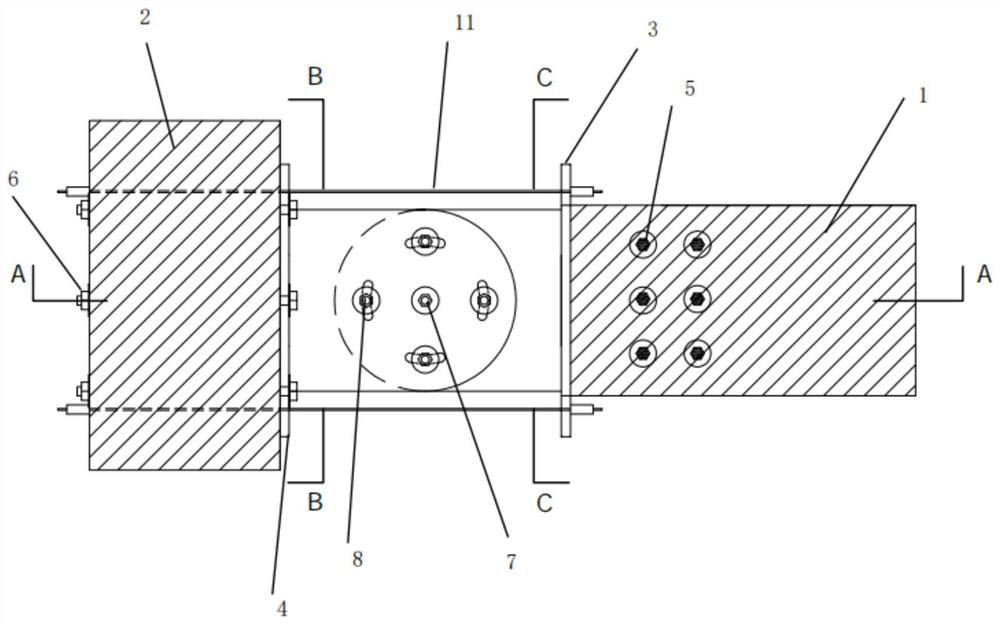

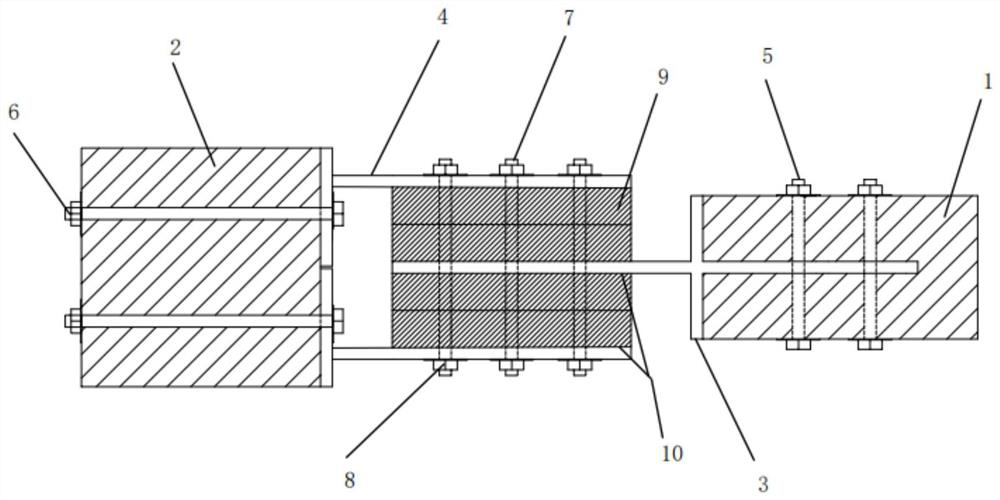

[0034] refer to figure 1 figure 2 image 3 , a beam-column frictional energy-dissipating node for a glued wood structure, comprising a glued-wood beam 1, a glued-wood column 2 and a rotational frictional energy-dissipating node, the glued-wood beam 1 is vertically connected to the glued-wood column 2.

[0035] The end of the glued wood beam 1 is preset with a round hole matching with the common bolt 5 and a notch matching with the connecting plate 3 at the beam end.

[0036] Such as Figure 4 Figure 5 As shown: the middle part of the glued wood column 2 is preset with a round hole matching with the ordinary bolt 6 and a hole matching with the shape memory alloy wire 11 .

[0037] Rotational friction energy dissipation nodes include beam end connection plates 3, two column end side connection plates 4, shaft bolts 7, four pre-tightening bolts 8 and four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com