Energy dissipater for wall vertical connecting seam

A technology of energy dissipators and joints, applied in the direction of walls, building components, building structures, etc., can solve the problems of unclear force transmission path and poor bearing capacity, and achieve the effect of improving the scope of application and flexibly adjusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the following specific examples will further describe the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

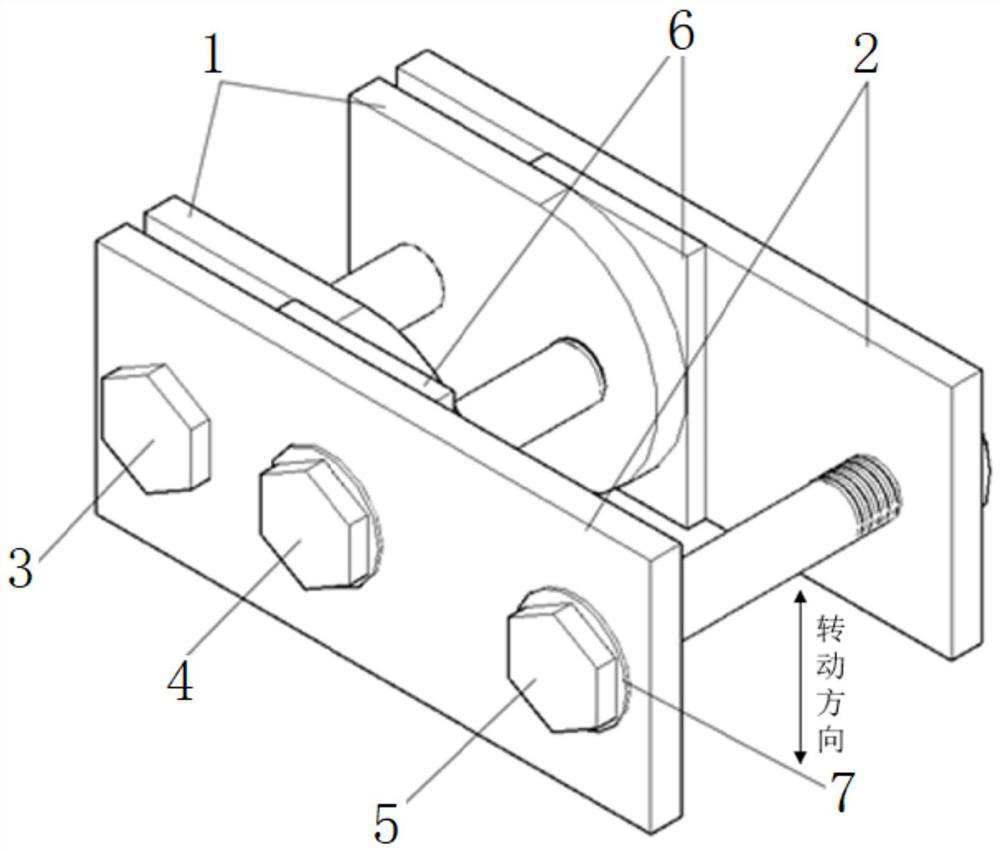

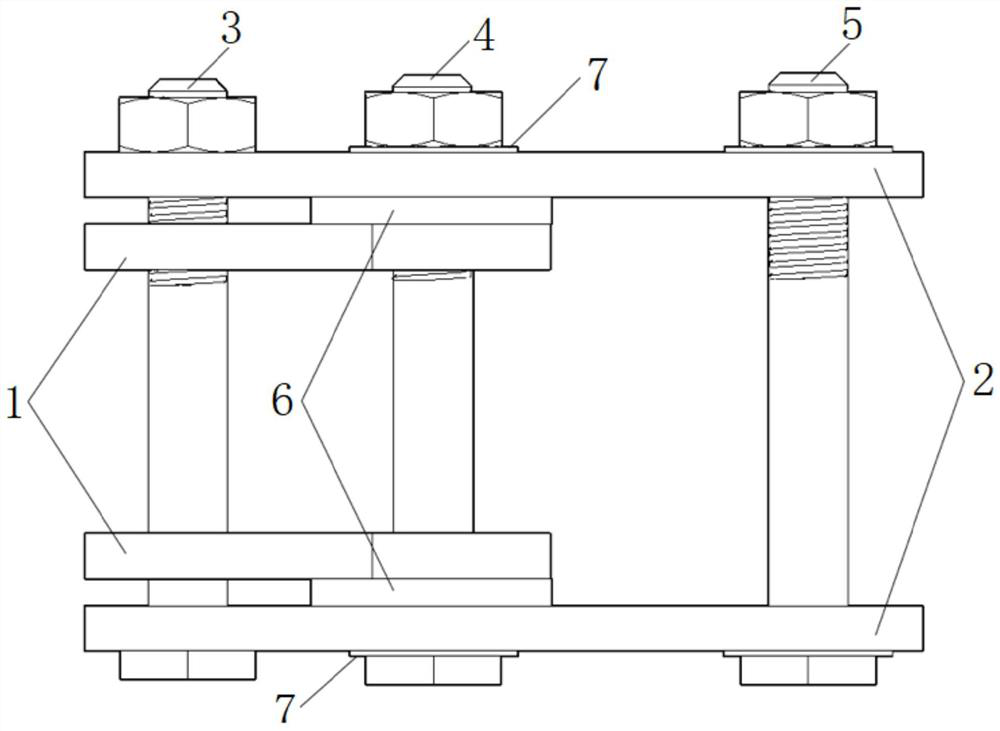

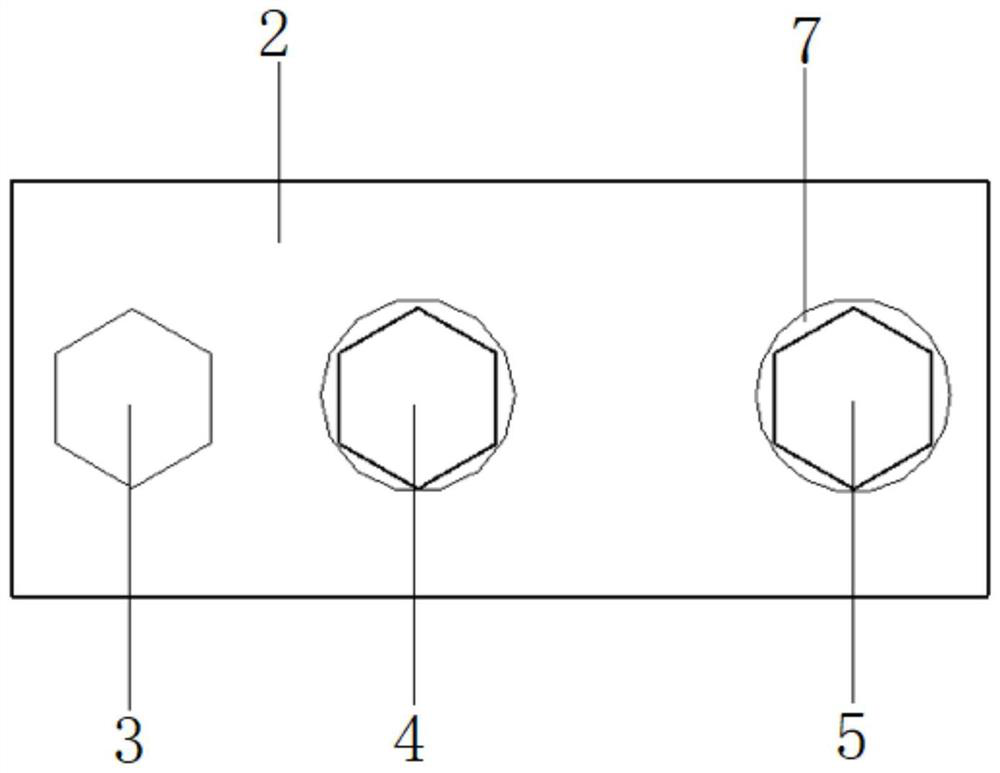

[0031] as attached Figure 1-7 As shown, the present invention provides an energy dissipator for vertical joints of walls, the energy dissipator is horizontally arranged between two adjacent vertical joints of walls; the energy dissipator includes two One ear plate 1, two actuating plates 2, energy dissipation bolts 3, fulcrum bolts 4, connecting bolts 5, two filler plates 6 and two reinforcement plates 10.

[0032] The ear plate 1 and the operating plate 2 are arranged horizontally at the vertical joints of two adjacent walls, the two operating plates 2 are vertically arranged in parallel, and the two ear pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com