Floor pit repairing equipment for indoor decoration

A technology for interior decoration and flooring, which is applied in transportation and packaging, mixers, construction, etc. It can solve the problems of time-consuming and labor-intensive, heavy workload of ground pits, etc., and achieve the effect of uniform mixing, heavy workload and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

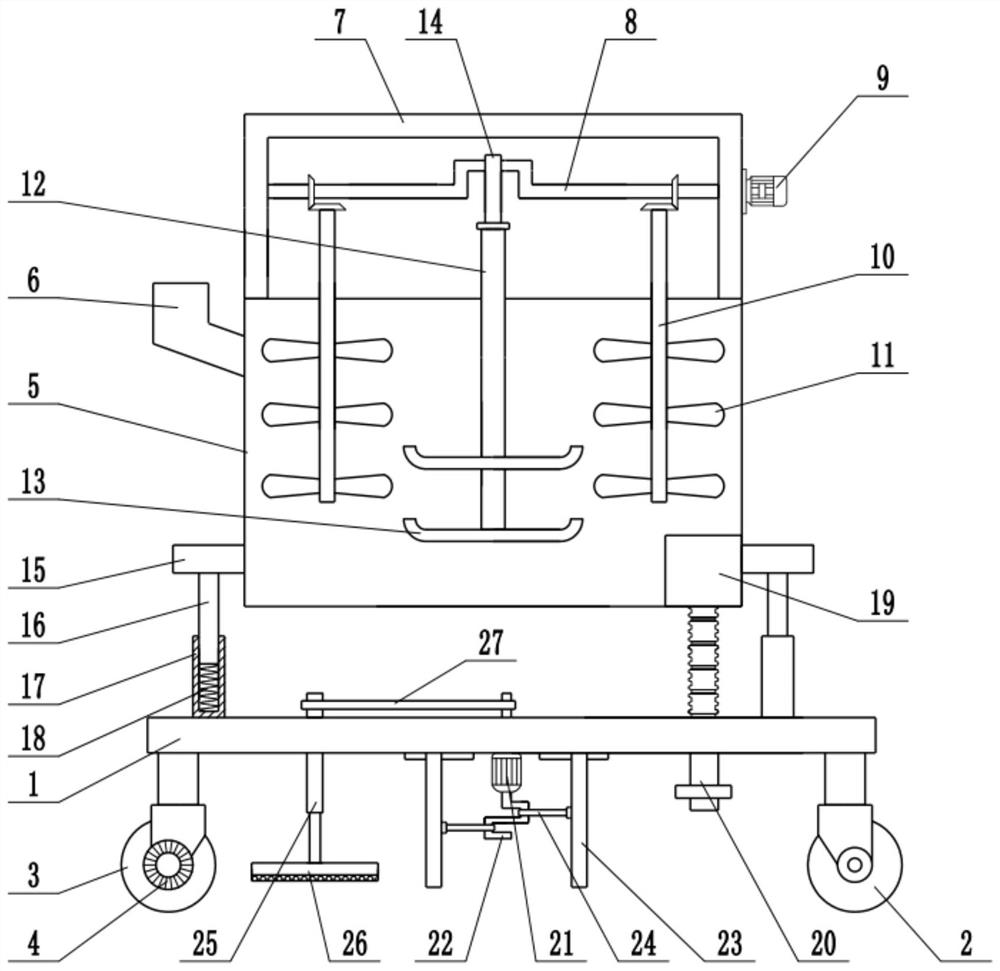

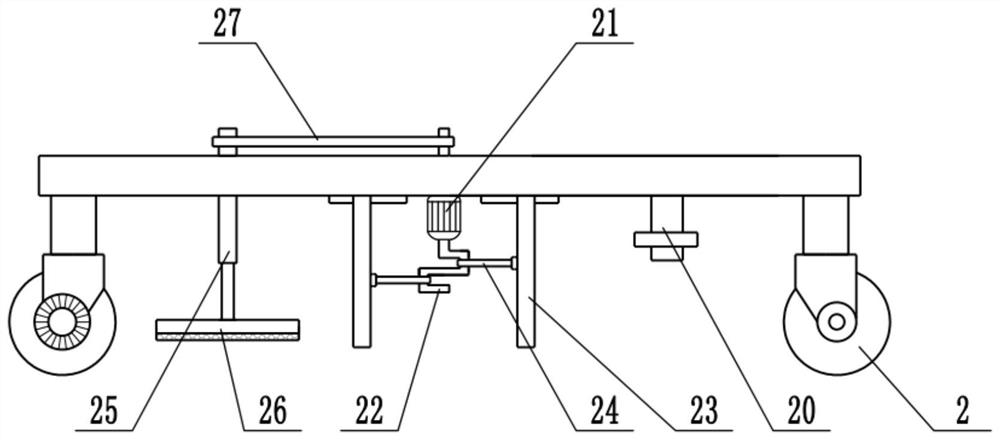

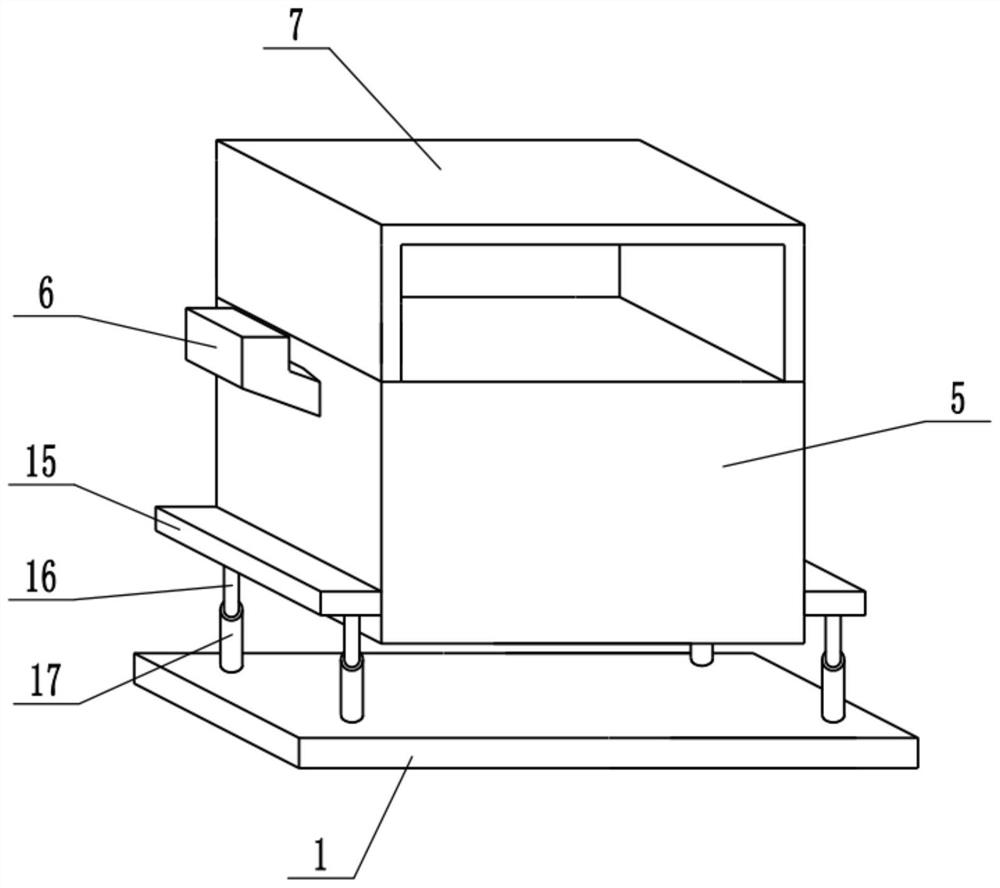

[0022] see Figure 1-3 , in the embodiment of the present invention, a kind of equipment for repairing ground pits for indoor decoration, comprising frame 1, front wheel 2, rear wheel 3, mixing box 5, feed pump 19 and discharge pipe 20, frame 1 The lower surface is fixedly connected with the front wheel 2 and the rear wheel 3, and the drive motor 4 is installed on the rear wheel 3 to drive the device to move. The top of the frame 1 is provided with a mixing box 5, and the side wall of the mixing box 5 is installed There is a feeding port 6, and the raw material of the repairing agent is put into the mixing box 5 through the feeding port 6. The top of the mixing box 5 is fixedly connected with a fixed frame 7, and the inside of the fixed frame 7 is equipped with a first crankshaft 8, and the outer wall of the fixed frame 7 A mixing motor 9 is fixedly connected, and the shaft extension end of the mixing motor 9 is connected with the end of the first crankshaft 8. The inside of t...

Embodiment 2

[0024] On the basis of Embodiment 1, the side wall of the mixing box 5 is also equipped with a vibration mechanism, the vibration mechanism includes a fixed plate 15, a guide rod 16, a sleeve 17 and a spring 18, and the left and right sides of the mixing box 5 are fixedly connected respectively. There is a fixed plate 15, the lower surface of the fixed plate 15 is fixedly connected with a guide rod 16, the lower end of the guide rod 16 is covered with a sleeve 17, the sleeve 17 is slidingly connected with the guide rod 16, and the bottom of the sleeve 17 is fixed to the frame 1 Connected, the inside of the sleeve 17 is equipped with a spring 18. When the device is running, the mixing motor 9 is used to drive the first crankshaft 8 to rotate, thereby driving the lifting rod 12 to move up and down through the first connecting rod 14, thereby driving the mixing disc 13 Move up and down, use the mixing disc 13 to drive the repairing agent raw materials in the mixing box 5 to toss u...

Embodiment 1、 Embodiment 2

[0025]In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: put the repairing agent raw material into the mixing box 5 through the feeding port 6, start the mixing motor 9, and drive the first crankshaft 8 to rotate, thereby driving the stirring shaft 10 to rotate , using the stirring blade 11 to stir the raw materials of the repairing agent to mix the raw materials of the repairing agent evenly. When the first crankshaft 8 rotates, the first connecting rod 14 drives the lifting rod 12 to move up and down, thereby driving the mixing plate 13 to move up and down. The disk 13 drives the raw materials of the repairing agent in the mixing box 5 to toss up and down, so that the raw materials of the repairing agent are mixed more evenly. Evenly, when it is necessary to repair the depressions on the indoor ground, start the feed pump 19, transport the repairing agent to the discharge pipe 20, spray it on the ground depressions, use the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com