Bearing lubrication structure of screw blower or vacuum pump

A bearing lubrication and blower technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problems of occupying and occupying the axial length space of the bearing and the axial space of multiple bearings, and achieves the Easy to manufacture, conducive to compactness and small space occupation

Active Publication Date: 2022-06-03

浙江珂勒曦动力设备股份有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The existing technical solutions above have the following defects: before the lubricating oil enters the bearing, an oil supply channel must be provided in front of the bearing end, which will occupy the axial length of the bearing, and the oil collection ring will also occupy the axial length of the bearing space; the bearing lubrication structure occupies more space in the axial direction of the bearing, which is not conducive to the compactness and miniaturization of the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

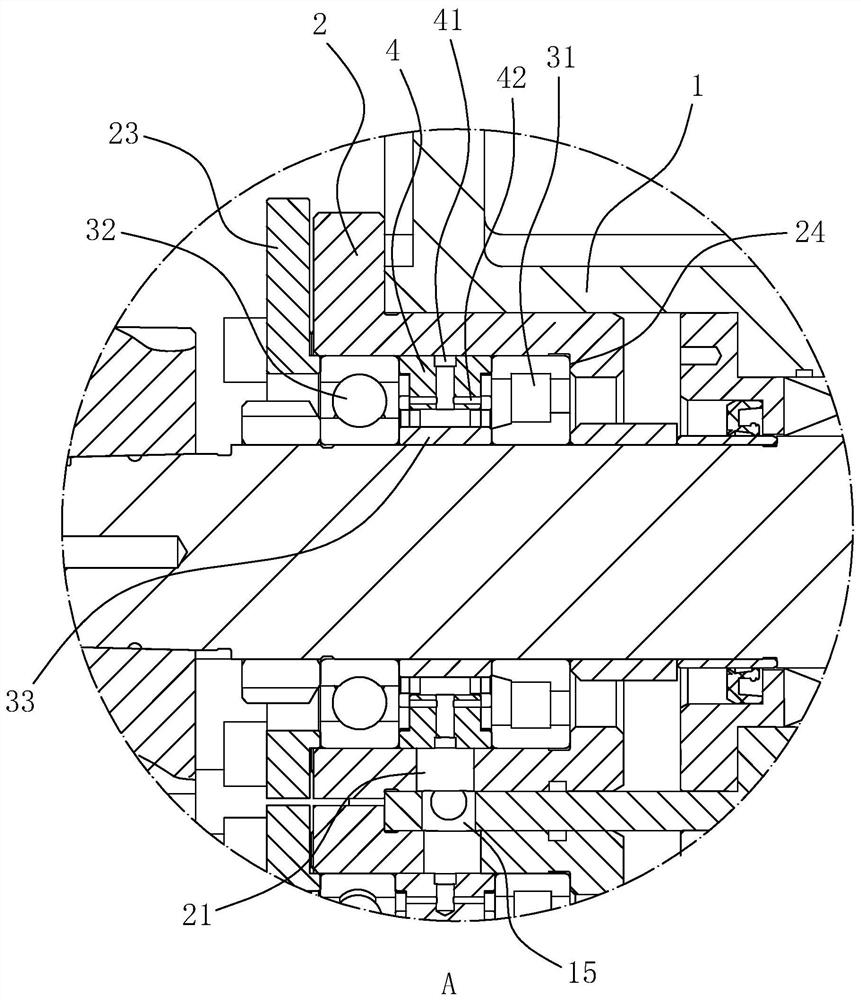

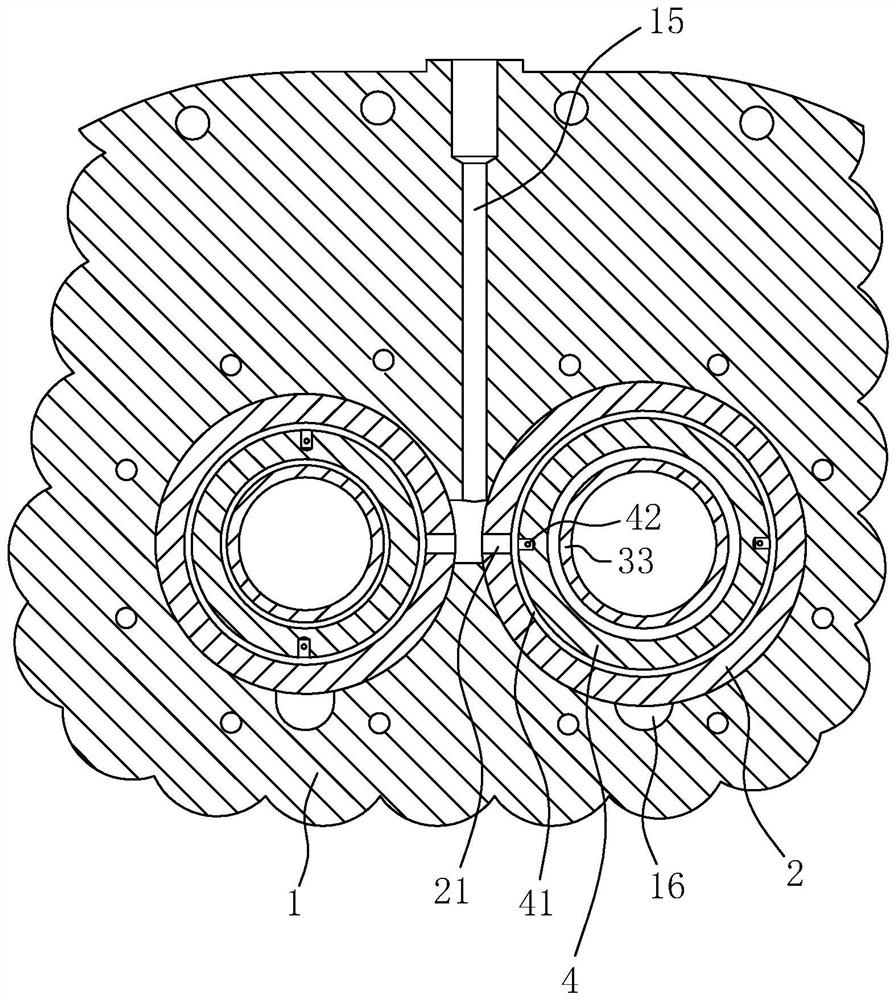

[0041] The oil separator ring 4 abuts the outer ring end surfaces of the first bearing 31 and the second bearing 32 through the outer edges of the two end surfaces, and the first bearing

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

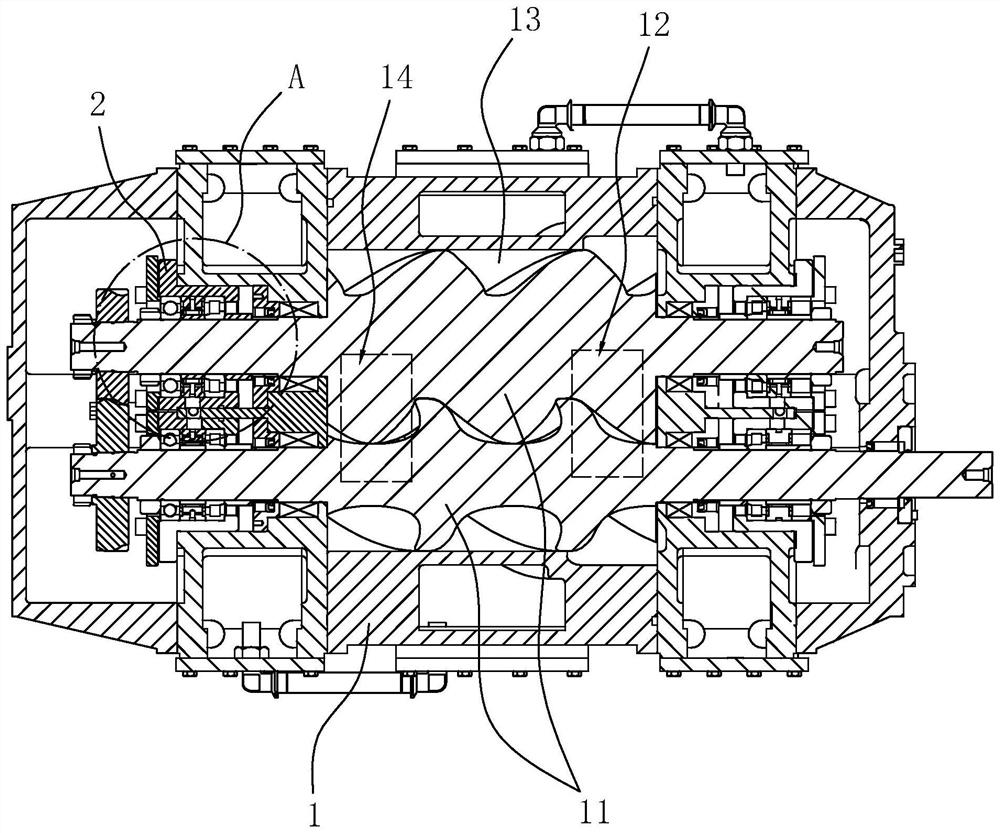

The invention discloses a bearing lubricating structure for a screw blower or a vacuum pump, and relates to a lubricating structure. The key points of the technical solution are: a casing and a bearing seat, the bearing seat is provided with a first bearing, and the casing is provided with an oil inlet passage , oil outlet passage, the bearing seat is provided with an oil inlet hole connected to the oil inlet passage, and an oil collection hole connected to the oil outlet passage. The groove is connected to the oil inlet hole, and the end surface of the oil distribution ring is provided with a number of oil outlet holes, the oil outlet holes are facing the first bearing, and the oil outlet holes are connected to the ring groove; the oil inlet hole and the oil collection hole are located in the first bearing At the same position in the axial direction, the oil distribution ring is provided with an oil passage groove near the oil collection hole, and the oil passage groove penetrates from the outer ring surface of the oil distribution ring to the inner ring surface of the oil distribution ring, and the oil collection hole is facing the oil passage groove . The bearing lubricating structure occupies less space in the axial direction of the bearing, which is beneficial to the compactness and miniaturization of the product; the disassembling and manufacturing of the bearing lubricating structure are relatively convenient.

Description

Bearing lubrication structure of screw blower or vacuum pump technical field The present invention relates to a kind of lubricating structure, particularly the bearing lubricating structure of screw blower or vacuum pump. Background technique [0002] The screw blower is a device that utilizes a pair of screws to perform synchronous reverse rotation in the housing to generate exhaust. The working principle and structure of the screw vacuum pump are basically the same as those of the screw blower, the difference is that the exhaust port of the screw blower It is the working end, and the suction port of the screw vacuum pump is the working end. A rotary connection is established between the screw and the shell through bearings, and the screw drum Fans or vacuum pumps are generally provided with lubricating structures for lubricating bearings. Existing application publication number is that the Chinese invention patent application of CN109139708A discloses a kind of bear...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F04C18/16F04C25/02F04C29/02

CPCF04C18/16F04C25/02F04C29/02F04C2240/56

Inventor 许祖近刘永胜

Owner 浙江珂勒曦动力设备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com