Optical fiber current sensor for realizing non-reciprocal dynamic phase modulation and corresponding signal demodulation method

A phase modulator and dynamic phase technology, applied in nonlinear optics, voltage/current isolation, measuring current/voltage, etc., can solve problems such as inability to meet current measurement requirements in new scenarios, and achieve improved measurement range, reduced noise, and high Measuring Bandwidth Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

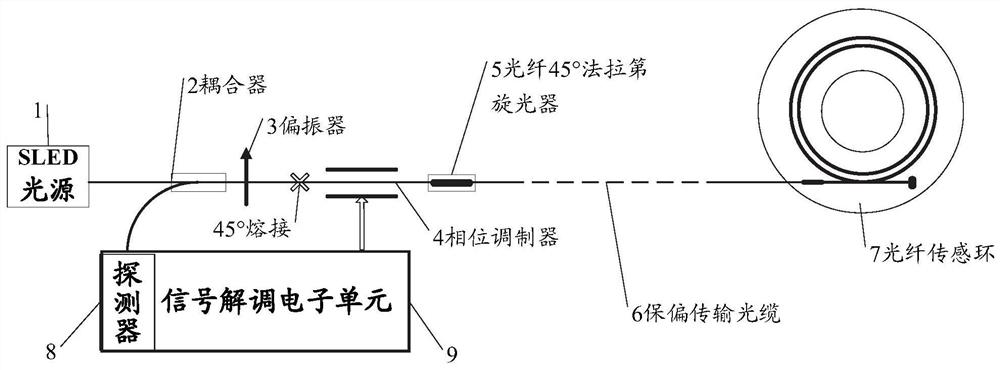

[0036] The fiber-optic current sensor realizing non-reciprocal dynamic phase modulation of the present invention includes a low-polarization SLED light source 1, a fiber coupler 2, a fiber polarizer 3, a straight waveguide phase modulator 4, a Faraday rotator 5, and a polarization-maintaining transmission Optical cable 6, optical fiber sensing ring 7, detector 8 and signal demodulation electronic unit 9, described low-bias type SLED light source 1 is connected to optical fiber coupler 2 through single-mode optical fiber; described optical fiber coupler 2 and optical fiber polarization The optical fiber polarizer 3 is fused with the straight waveguide phase modulator 4 at 45°, and the other end of the straight waveguide phase modulator 4 is fused with the input end of the Faraday rotator 5; the Faraday The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com