Material taking mechanism of rapid assembly equipment for capacitor machining

A technology of mechanical processing and assembling equipment, which is applied in the direction of capacitors, capacitor manufacturing, circuits, etc., can solve the problems of capacitor damage, high maintenance cost, high cost, etc., and achieve the effect of close connection, simple stroke, streamlined and efficient driving components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

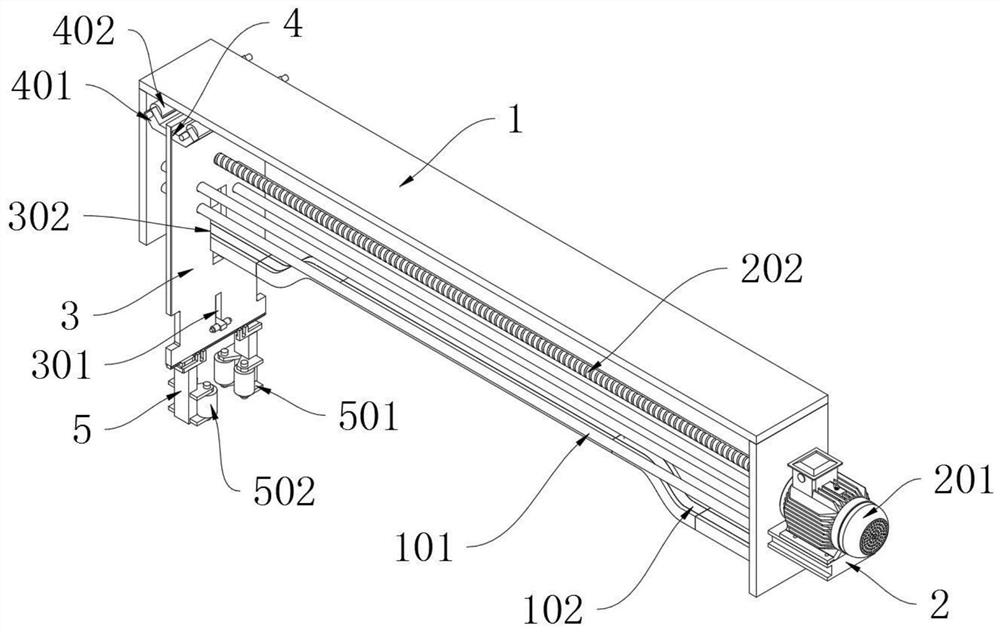

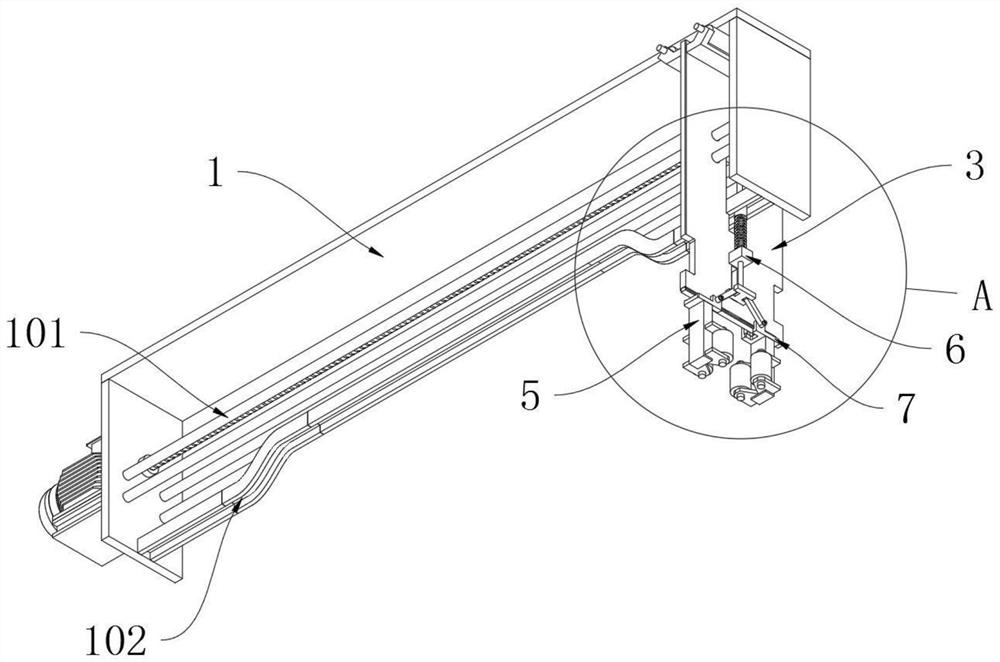

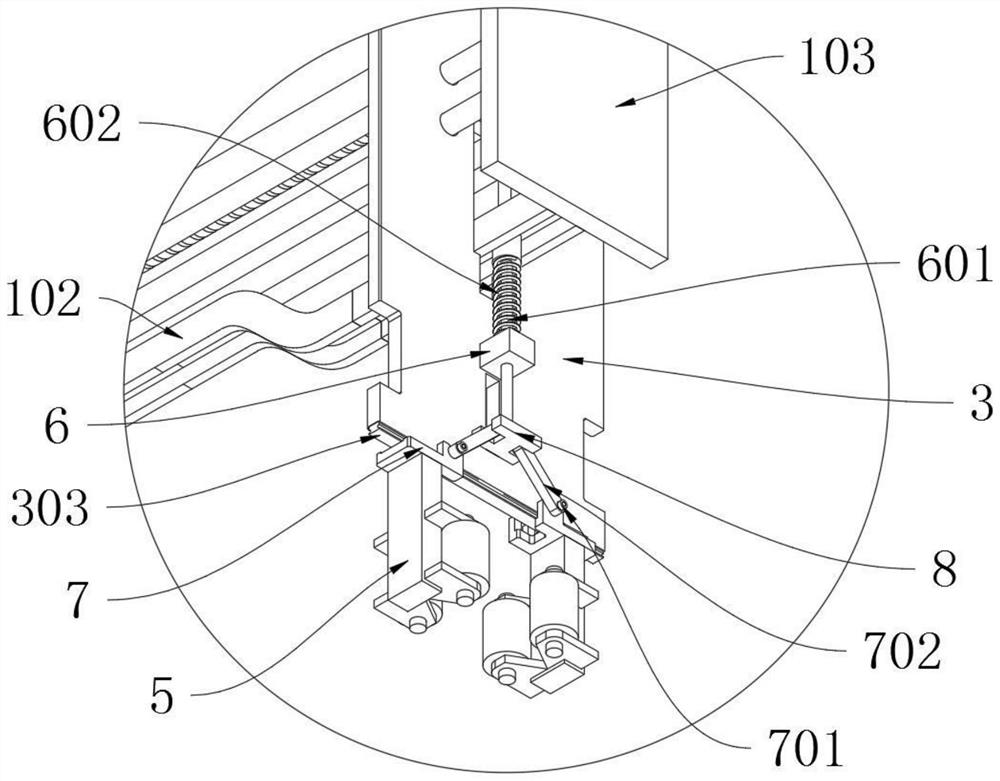

[0037] as attached figure 1 to attach Figure 8 Shown:

[0038] The present invention provides a material retrieving mechanism for rapid assembly equipment for machining capacitors, which includes a truss 1; a horizontal drive mechanism 2 is installed laterally at the lower end of the truss 1; the truss 1 includes a guide rod 101, a guide rail 102 and an end plate 103, The end plate 103 is fixedly installed vertically downward at the left end edge and the right end edge of the bottom plane of the truss 1, and four guide rods 101 arranged in a rectangular shape are fixedly installed between the two end plates 103, while the reclaimer 3 is Slidingly sleeved on the guide rod 101, the lower ends of the opposite side walls of the two end plates 103 are fixedly equipped with guide rails 102 with low middle parts and high left and right ends, and the front and rear edges of the guide rails 102 are all fixed. A protruding edge plate is installed, and the guide rail 102 slides throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com