A kind of preparation method of bimetallic sulfide for sodium-sulfur secondary battery

A secondary battery, bimetal technology, applied in the field of preparation of bimetallic sulfides, can solve the problems of weak polarity of carbon materials, not very good conductivity, not very satisfactory effect, etc., and achieve good cycle performance and rate performance , Improve the effect of catalytic conversion and alleviate the effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

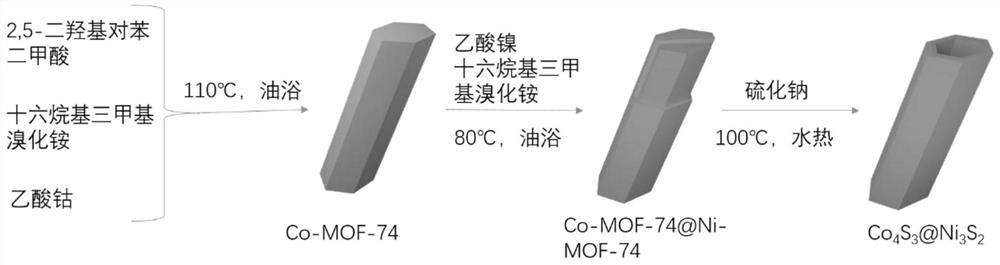

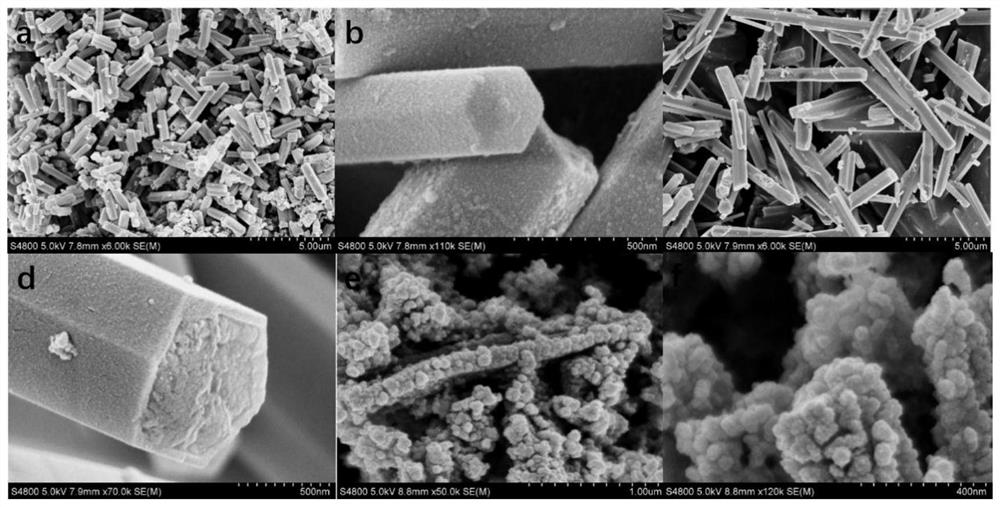

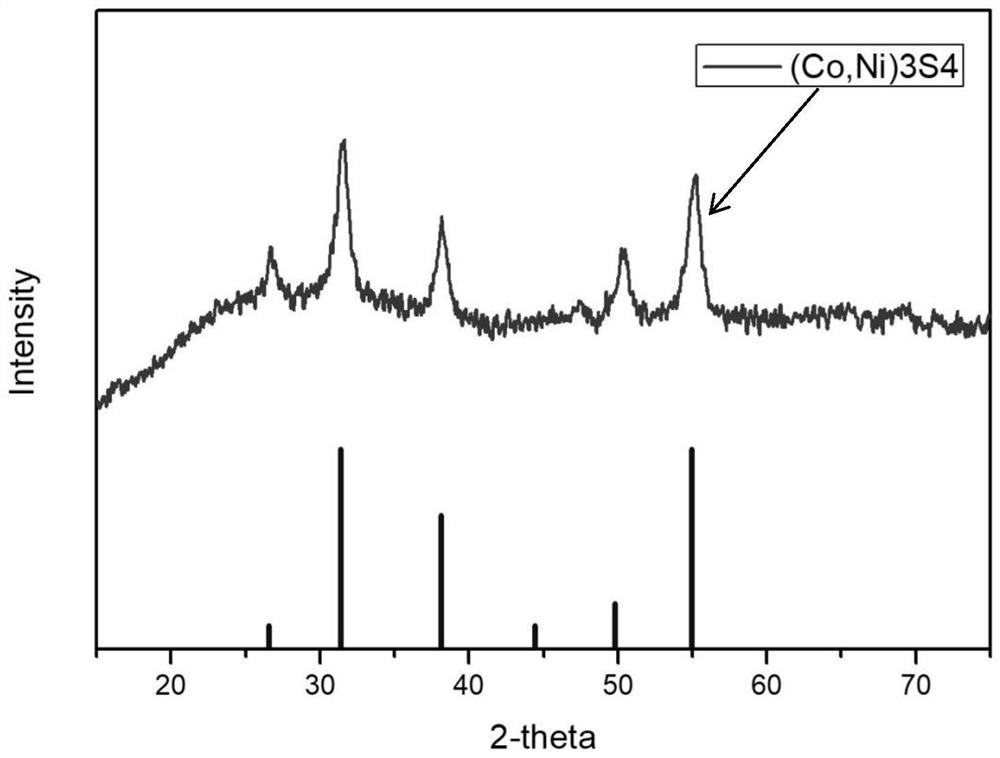

[0032] (Co,Ni) for sodium-sulfur cathode support materials 3 S 4 Bimetallic sulfides, including the following raw material components: 2,5-dihydroxyterephthalic acid, cobalt acetate, nickel acetate, cetyltrimethylammonium bromide; as a preferred solvent, ethanol, tetrahydrofuran, Deionized water.

[0033] (Co,Ni) used as positive electrode carrier material for sodium-sulfur batteries 3 S 4 Bimetallic sulfides, comprising the steps of:

[0034] Step 1: Dissolve 4mol of 2,5-dihydroxyterephthalic acid in 40ml of tetrahydrofuran.

[0035] Step 2: Dissolve 4 mol of cobalt acetate and 1 g of cetyltrimethylammonium bromide in 40 ml of deionized water, mix the two solutions, and stir vigorously for 10 min.

[0036] Step 3: Transfer the mixed solution to a silk bottle, put it in an oil bath at 110°C, and keep it warm for 3 hours under the condition of stirring.

[0037] Step 4: Cool the solution to room temperature, centrifuge, and wash three times with absolute ethanol and deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com