Electric heating and heating device for automobile exhaust emission

A technology of automobile exhaust and heating device, which is applied in exhaust device, muffler device, air quality improvement and other directions, can solve the problem of complex structure of air guide and heat exchange tube system, low heating and heating speed of exhaust gas, and ineffective catalytic converter, etc. It can improve the effect of catalytic conversion, facilitate uniform heating, and reduce automobile exhaust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

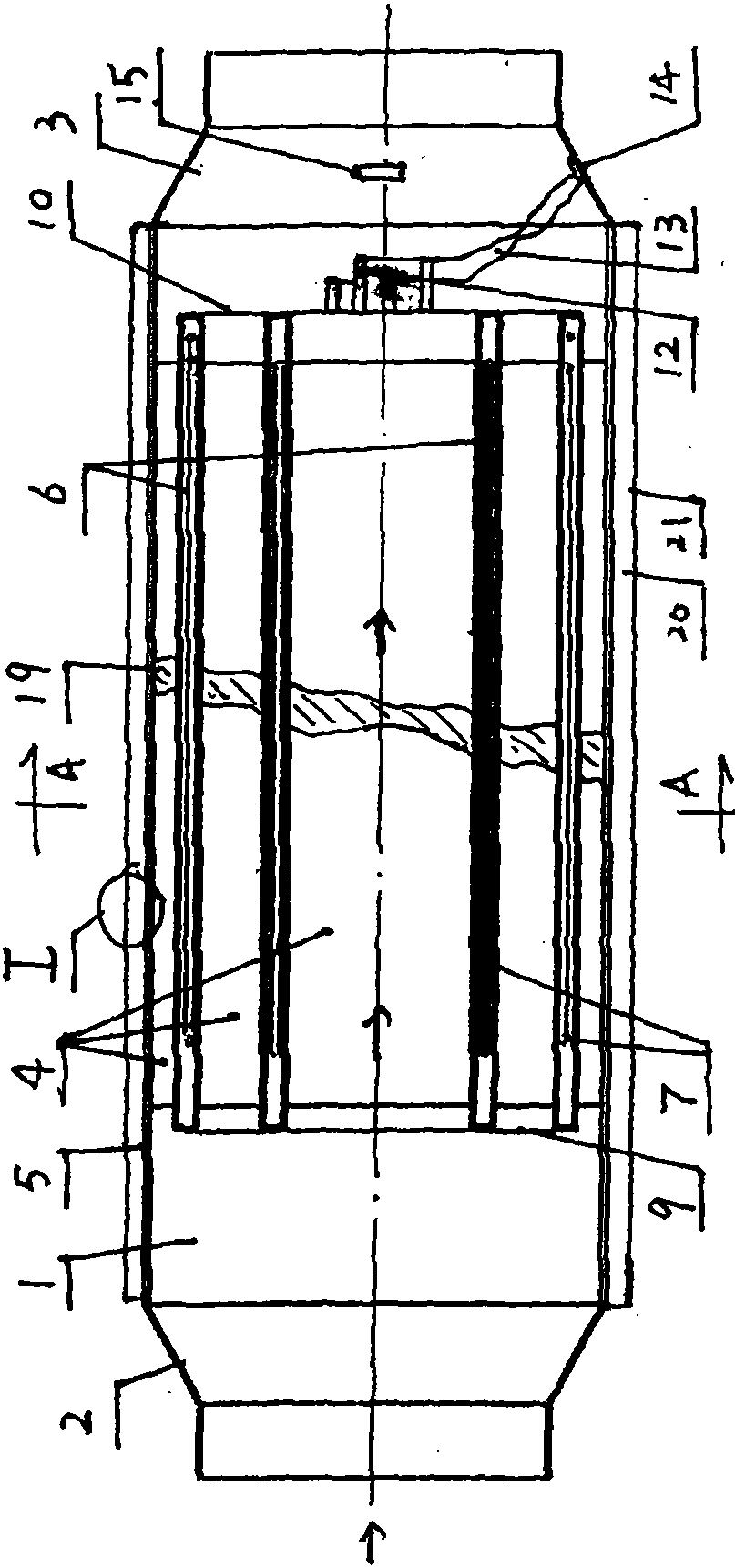

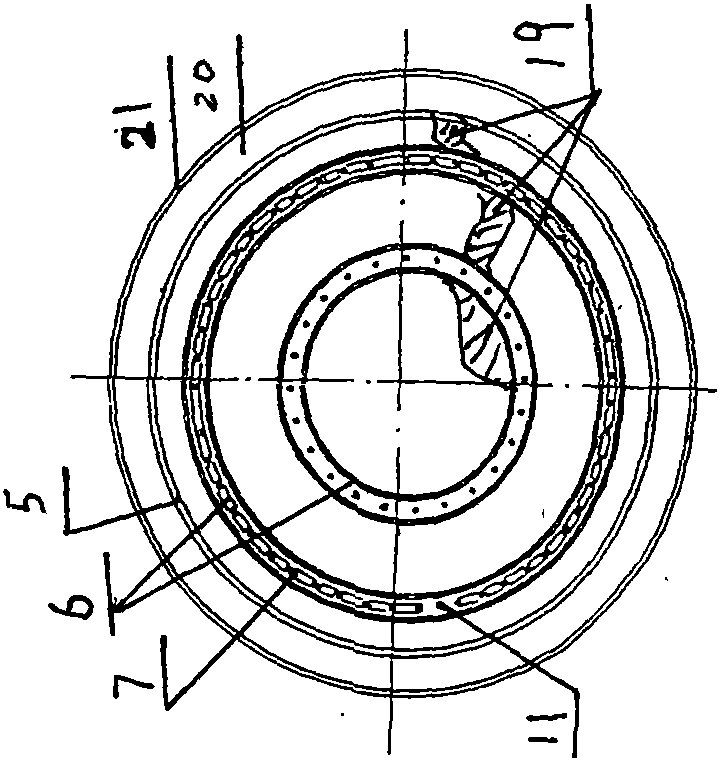

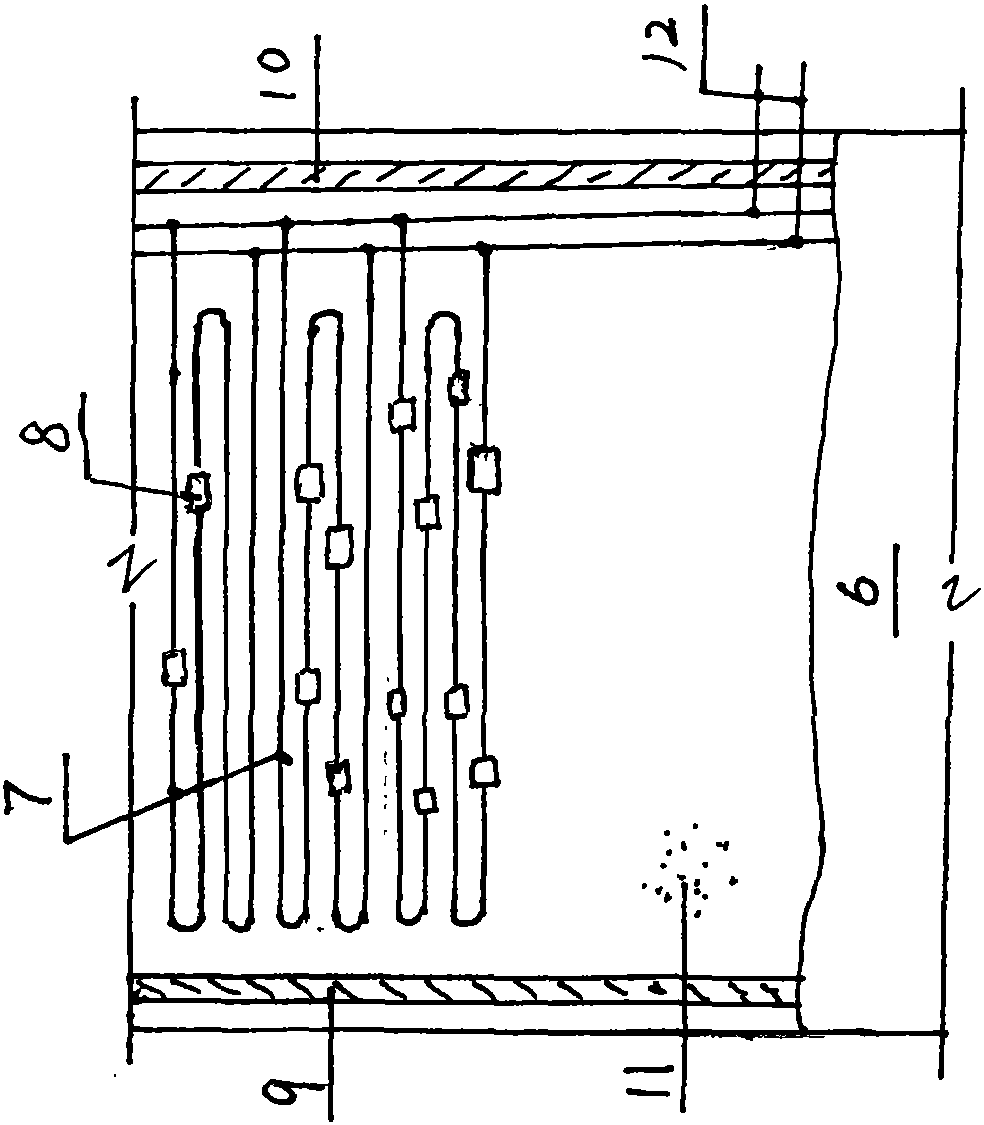

[0016] Further detailed description in conjunction with the accompanying drawings; the arrows in the figure indicate the flow direction of the exhaust gas.

[0017] Such as Figure 1-6 As shown, the electric heating and temperature-raising device for automobile exhaust emission has a housing with an outer heat insulation layer 20, an electric heater and an electric control mechanism; The left and right ports 2 and 3 of the exhaust gas on the top are composed; the main body 1 is composed of 2 to 8 air guiding cylinders 4 in turn from the outside to the inside, and each air guiding cylinder 4 is fixed with a honeycomb packing body 19; the outermost air guiding cylinder 4 is composed of the outer cylinder 5 and the outermost electric heater sleeve 6, the innermost air guide cylinder 4 is composed of the innermost electric heater sleeve 6, and the middle air guide cylinder 4 is composed of two corresponding adjacent electric heater sleeves. Composed of heater sleeves 6, the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com