Copper-phosphorus welding ring, and preparation method and application thereof

A welding ring and copper-phosphorus technology, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of steel brazing seam strength and cost can not be taken into account, so as to broaden the scope of use, improve brazing seam connection strength, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

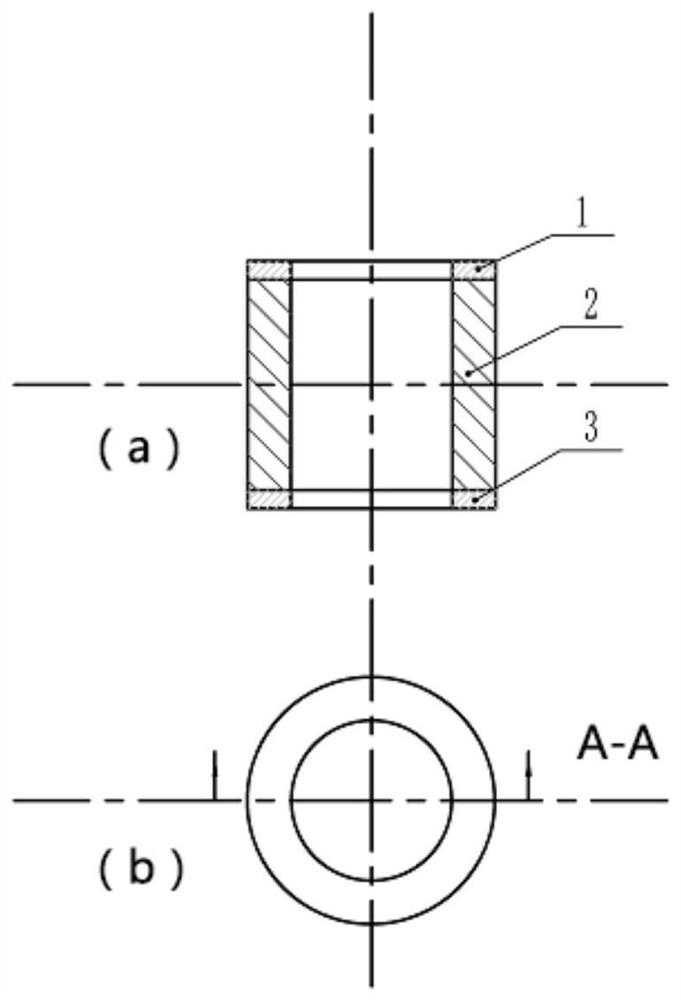

[0072] This embodiment provides a copper-phosphorus welding ring and a preparation method thereof, the structure of the copper-phosphorus welding ring is as follows figure 1 As shown, the copper-phosphorus welding ring includes 70 parts of copper-phosphorus solder, 10 parts of flux and 20 parts of anhydrous copper sulfate in parts by weight.

[0073] The preparation method of the above-mentioned copper-phosphorus welding ring comprises the following steps:

[0074] (1) Adopt atomization method to prepare powdery copper-phosphorus brazing filler metal according to following proportioning, pass the obtained copper-phosphorus brazing filler metal through 100 mesh sieves, obtain material A; Wherein, copper-phosphorus brazing filler metal comprises copper 88 by mass percentage %, phosphorus 7%, silver 5%;

[0075] (2) adopt mechanical mixing method to prepare powdery brazing flux by following proportioning, the powdery brazing flux that is obtained is crossed 100 mesh sieves, obta...

Embodiment 2

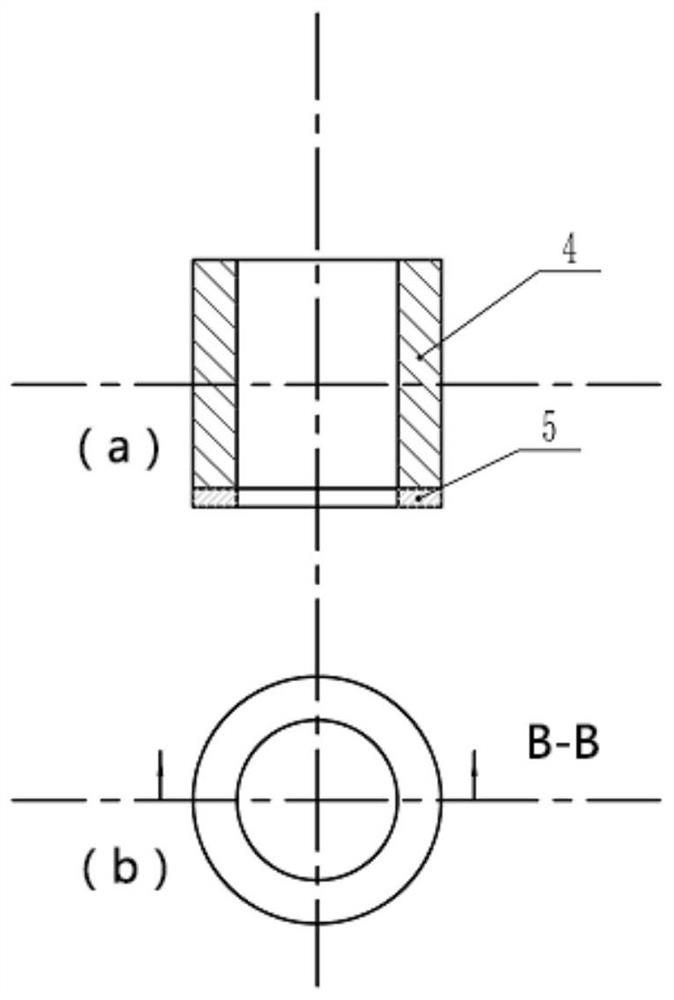

[0080] This embodiment provides a copper-phosphorus welding ring and a preparation method thereof, the structure of the copper-phosphorus welding ring is as follows figure 2 As shown, the copper-phosphorus welding ring includes 80 parts by weight of copper-phosphorus solder, 15 parts of flux and 5 parts of anhydrous copper sulfate.

[0081] The preparation method of the above-mentioned copper-phosphorus welding ring comprises the following steps:

[0082] (1) Adopt atomization method to prepare powdery copper-phosphorus brazing filler metal according to following proportioning, pass the obtained copper-phosphorus brazing filler metal through 100 mesh sieves, obtain material A; Wherein, copper-phosphorus brazing filler metal comprises copper 88 by mass percentage %, phosphorus 7%, silver 5%;

[0083] (2) adopt mechanical mixing method to prepare powdery brazing flux by following proportioning, the powdery brazing flux that is obtained is crossed 100 mesh sieves, obtains mater...

Embodiment 3

[0088] This embodiment provides a copper-phosphorus welding ring and a preparation method thereof, the structure of the copper-phosphorus welding ring is as follows figure 1 As shown, the copper-phosphorus welding ring includes 75 parts of copper-phosphorus solder, 12 parts of flux and 13 parts of anhydrous copper sulfate in parts by weight.

[0089] The preparation method of the above-mentioned copper-phosphorus welding ring comprises the following steps:

[0090] (1) Adopt atomization method to prepare powdery copper-phosphorus brazing filler metal according to following proportioning, pass the obtained copper-phosphorus brazing filler metal through 100 mesh sieves, obtain material A; Wherein, copper-phosphorus brazing filler metal comprises copper 88 by mass percentage %, phosphorus 7%, silver 5%;

[0091](2) adopt mechanical mixing method to prepare powdery brazing flux by following proportioning, the powdery brazing flux that is obtained is crossed 100 mesh sieves, obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com