Ecological smokeless environment-friendly garbage treatment system

A waste treatment system and an environmentally friendly technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of the decrease in the calorific value of pyrolysis gas and increase exhaust gas emissions, and achieve increased heating surface, reduced emissions, and excess combustible. The effect of gas increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

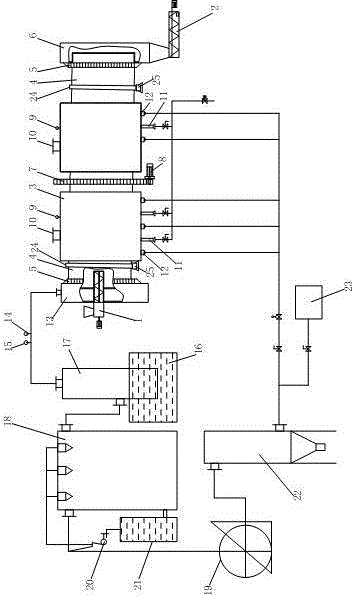

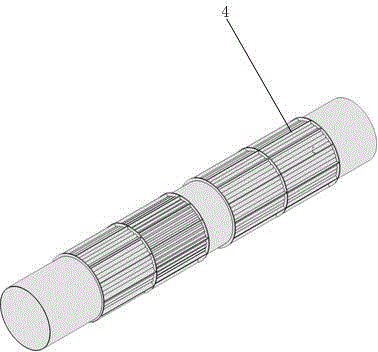

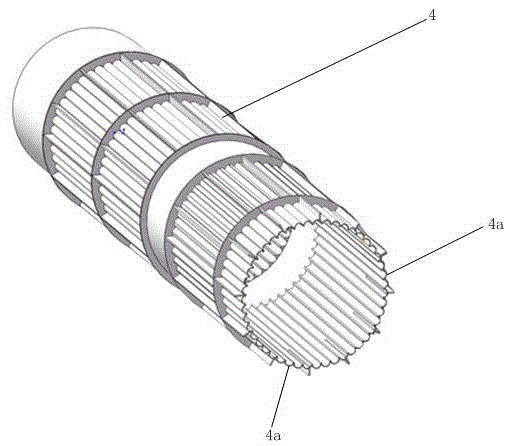

[0026] figure 1 Shown, a kind of ecological smokeless environment-friendly waste disposal system of this example, comprises screw type feeder 1, screw type discharger 2, combustion system, ignition system, wherein said combustion system comprises two combustion chambers 3, a Reactor 4, reactor 4 has two heating zones; and the heating zone of pyrolysis reactor 4 is spliced by some semicircular tubes 4a, as figure 2 , image 3 shown. The pyrolysis reaction kettle 4 passes through the combustion chamber 3, and one end of the pyrolysis reaction kettle 4 is connected with the gas collection device through the phosphorus plate sealer 5, and the screw feeder 1 passes through the gas collection device, and the phosphorus plate sealer 5 extends into the heat chamber. pyrolysis reaction kettle 4; the other end of the reaction kettle 4 is connected to the kiln tail sealing cover 6 through the phosphorus plate sealer 5, and the kiln tail sealing cover 6 is connected to the screw disc...

Embodiment 2

[0036] Figure 4 Shown, this example is basically the same as Embodiment 1, the difference is:

[0037]The combustion system of this example comprises a combustion chamber 3, a reaction kettle 4, and the reaction kettle 4 has a heating zone; One end of the reaction kettle 4 is connected to the gas collection device through the phosphorus plate sealer 5, and the screw feeder 1 passes through the gas collection device and the phosphorus plate sealer 5 and extends into the pyrolysis reaction kettle 4; the other end passes through the phosphorus plate sealer. 5 is connected to the kiln tail sealing cover 6, and the kiln tail sealing cover 6 is connected to the screw discharge machine 2; and the pyrolysis reaction kettle 4 is inclined to pass through the combustion chamber 3, so that the garbage is transported from the higher end to the kiln tail sealing Cover 6; the pyrolysis reactor 4 is also provided with a rotating device, the rotating device includes a rotating gear 7, a redu...

Embodiment 3

[0040] Figure 5 Shown, this example is basically the same as Embodiment 1, the difference is:

[0041] The combustion system of this example comprises three combustion chambers 3, a reactor 4, and reactor 4 has three heating zones; One end of the pyrolysis reaction kettle 4 is connected to the gas collecting device through a phosphorus plate sealer 5, and the screw feeder 1 is inserted into the pyrolysis reaction kettle 4 through the gas collecting device and the phosphorus plate sealer 5; the other end is sealed by a phosphorus plate The device 5 is connected to the kiln tail sealing cover 6, and the kiln tail sealing cover 6 is connected to the screw discharge machine 2; and the pyrolysis reaction kettle 4 is inclined to pass through the combustion chamber 3, so that the waste is transported from the higher end to the kiln tail Sealing cover 6; Pyrolysis reactor 4 is also provided with rotating device, and rotating device comprises rotating gear 7, speed reducer motor 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com