Plate positioning device, material containing mechanism, machining center and machining method

A technology for positioning devices and plate processing, applied in positioning devices, metal processing, metal processing equipment, etc., to achieve the effects of reduced area occupation, convenient operation, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

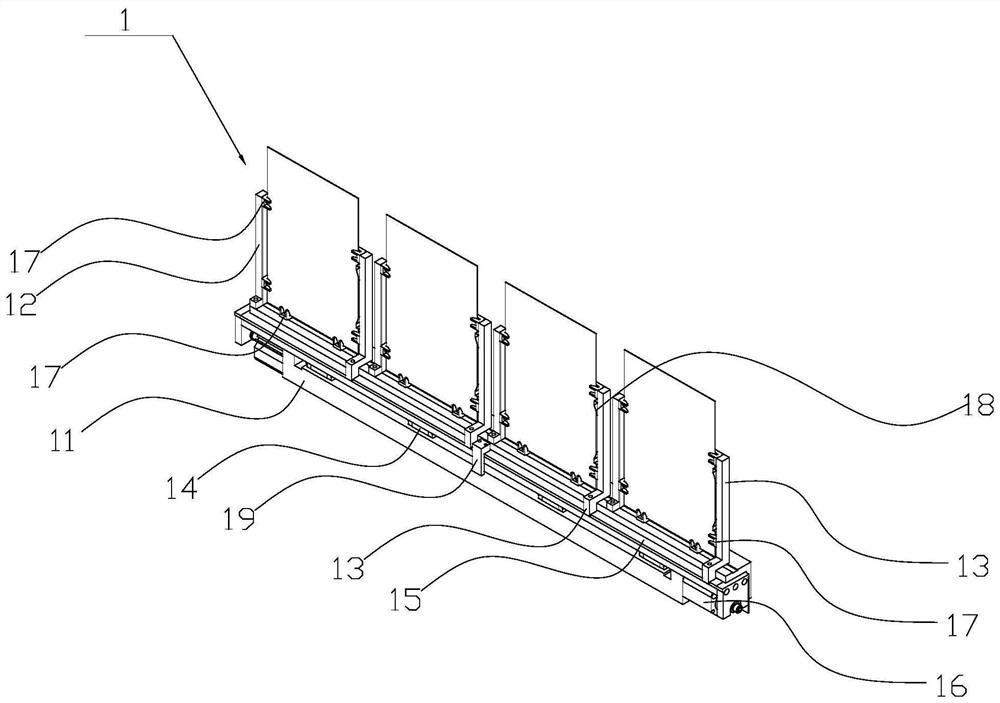

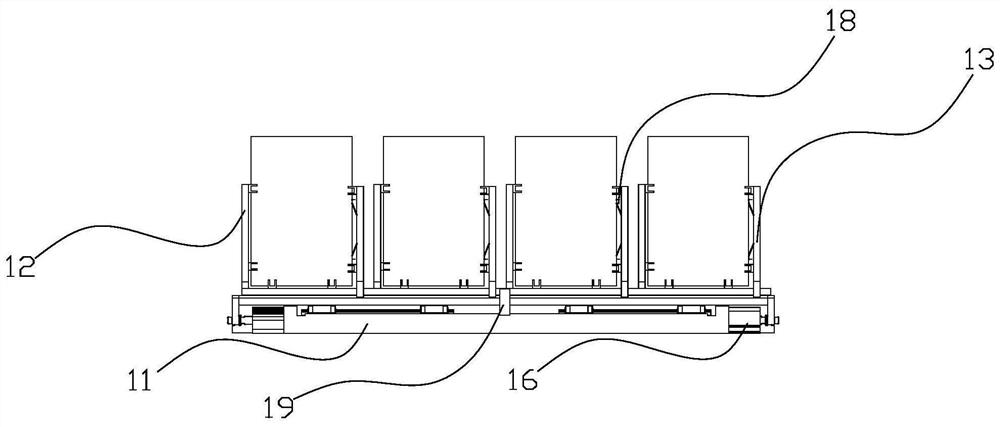

[0076] See attached Figure 1-2 , the embodiment of the present invention provides a plate positioning device 1, which is used for positioning the plate in the direction perpendicular to the machine tool of the plate processing center. The plate processing center includes a machine tool, a material tank and a workbench. Set parallel to the horizontal plane of the machine tool.

[0077] The positioning device 1 is an upright structure, which can be vertically arranged on the machine tool of the plate processing center and installed at the adjacent rear of the material trough, between the material trough and the workbench. In addition, the positioning device 1 can also be installed in front of the chute.

[0078] The positioning device 1 includes: a bracket 11 for installing the positioning device 1 on the plate processing center machine tool, a number of fixed positioning blocks 12 and movable positioning blocks 13 detachably installed on the bracket 11; the positioning device...

Embodiment 2

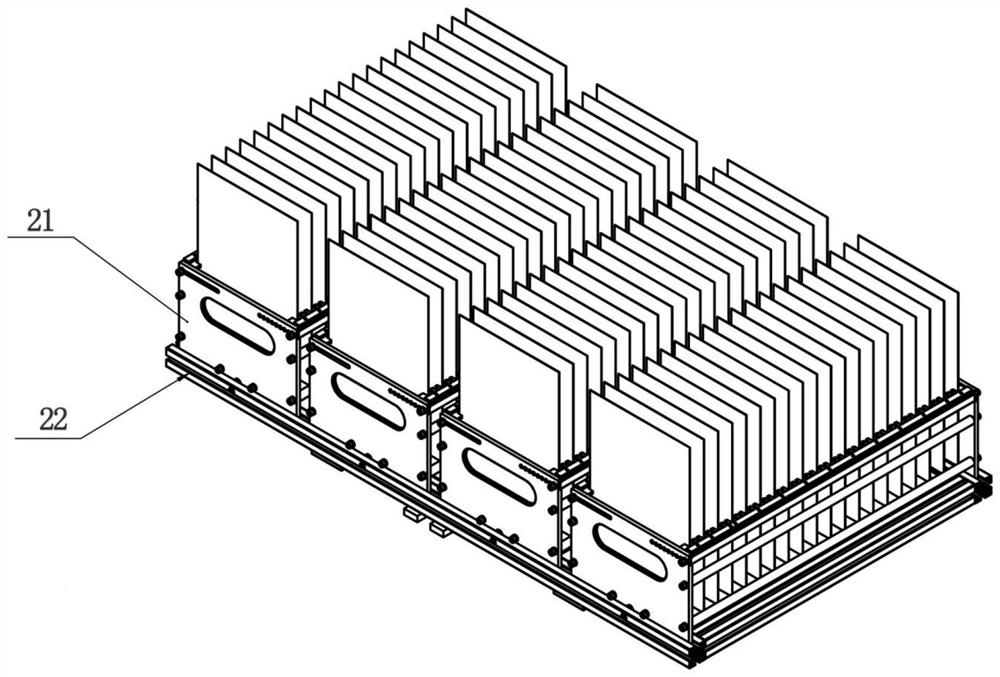

[0086] See attached Figure 3-4 , this embodiment provides a material holding mechanism for a plate processing center, including the positioning device 1 in the embodiment 1, and the material trough 2 . The trough 2 is matched with the positioning device 1 in the first embodiment.

[0087] The chute 2 includes a chute box 21 for holding plates, a tray 22 for receiving the chute box 21, a slide rail 23 is detachably installed on the machine tool of the plate processing center, and the tray 22 is installed on on the slide rail 23 and can slide left and right along the slide rail 23 .

[0088] The tray 22 is a frame-shaped space surrounded by a plurality of aluminum profiles, and a circular positioning rod 24 is arranged in the frame-shaped space for positioning the material chute box 21 in the left and right directions shown in the accompanying drawings. The tank box 21 is placed in the frame-shaped space.

[0089] The tray 22 is also provided with a drive block 25, the chute...

Embodiment 3

[0092] In order to facilitate the understanding of the technical solution in this embodiment, refer to the accompanying drawings, and take the operator standing in front of the machining center to face the angle of view of the machining head as a benchmark, define the X, Y, and Z axes as the Cartesian coordinate system, and the extension direction of the X axis as left and right Horizontally, the left side of the operator is the left side of the machining center, and the right side of the operator is the right side of the machining center; the extension direction of the Y axis is the front and rear longitudinal direction, the side close to the operator is the front side of the machining center, and the side away from the operator The side is the rear side of the machining center; the extension direction of the Z axis is vertical up and down.

[0093] See attached Figure 5-6 , the embodiment of the present invention provides a plate processing center, in addition to including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com