A squaraine-based organic porous polymer material and its preparation method and application

A porous polymer and squarylium-based technology, applied in the field of photocatalytic materials, can solve the problems of long reaction time and low reaction efficiency, and achieve the effects of simple operation, simple synthesis process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the squaraine-based organic porous polymer material applied to the positive electrode material of a lithium-sulfur battery is characterized in that the following steps are included:

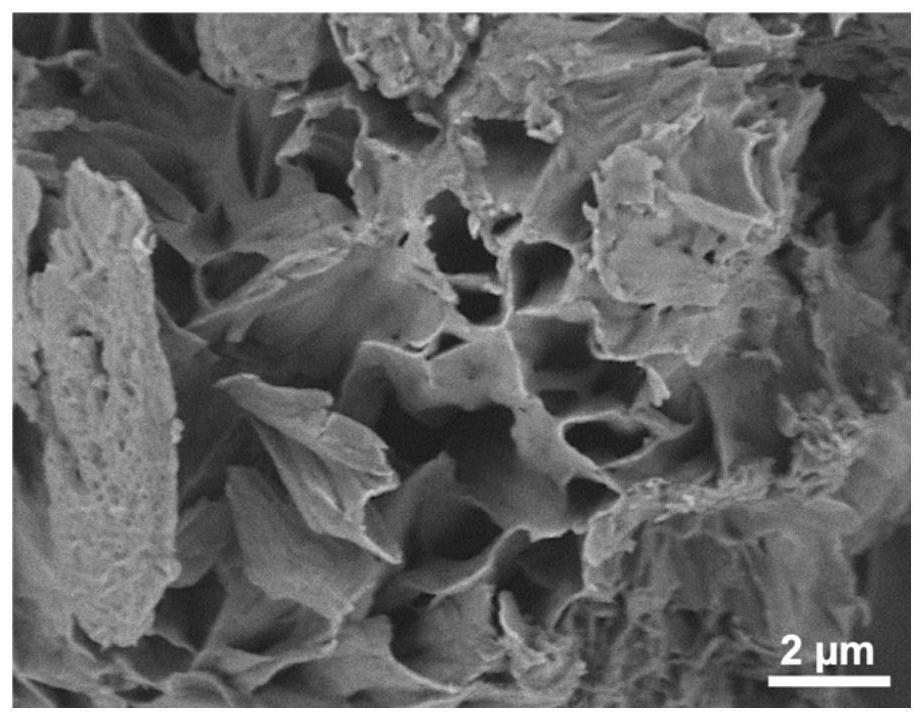

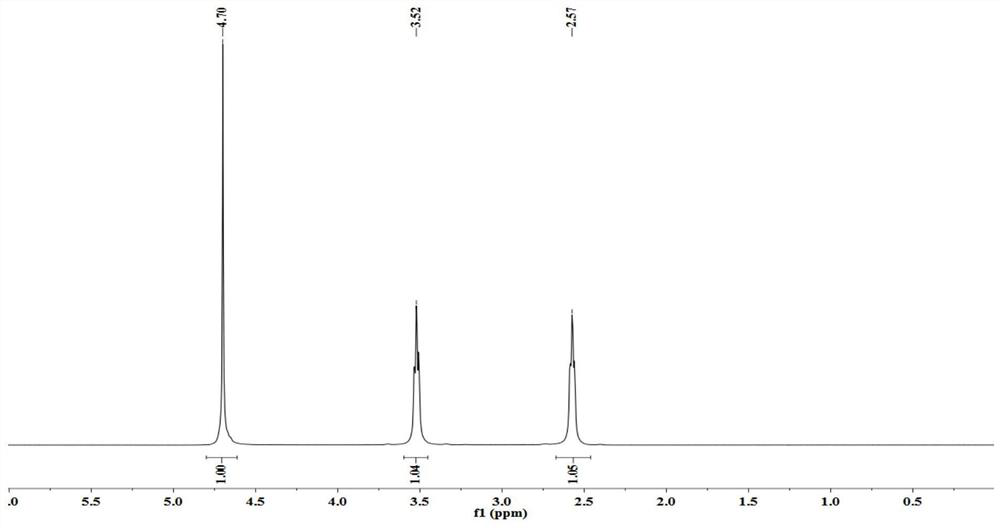

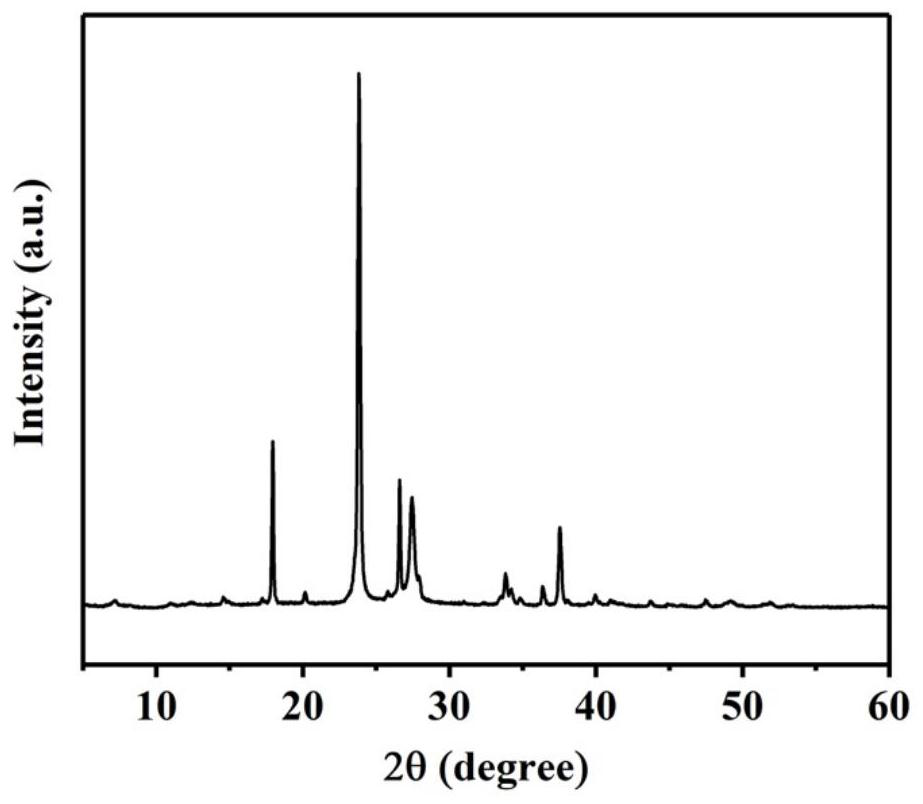

[0045] (1) Preparation of squaraine-based organic porous polymer material: 1.5 g of squaraine monomer and 1.0 g of melamine monomer were dissolved in 40 mL of n-butanol under an argon atmosphere, put into a microwave reactor, and with a power of 100 W, The reaction was carried out at 120 °C for 1 hour to complete the reaction. After cooling to room temperature naturally, the reaction system was transferred to a Buchner funnel, washed with acetone, tetrahydrofuran and dichloromethane for 5 times in turn, and dried in vacuum at 35 °C for 12 hours, a solid powder is obtained, which is the prepared squaraine-based organic porous polymer material. Thermogravimetric analysis showed that the decomposition temperature of the material was 400°C, indicating that the materia...

Embodiment 2

[0053] The preparation method of the squaraine-based organic porous polymer material applied to the positive electrode material of a lithium-sulfur battery is characterized in that the following steps are included:

[0054] (1) Preparation of squaraine-based organic porous polymer material: 2.1 g of squaraine monomer and 1.3 g of 1,3,5-triaminobenzene monomer were dissolved in 40 mL of n-butanol under argon atmosphere, and put into microwave reaction In the apparatus, with a power of 120W, react at 120 ° C for 2 hours to complete the reaction, after naturally cooling to room temperature, transfer the reaction system to a Buchner funnel, and wash with acetone, tetrahydrofuran and dichloromethane repeatedly for 5 times in turn. Vacuum-drying at 40° C. for 12 hours to obtain solid powder, which is the prepared squaraine-based organic porous polymer material. The decomposition temperature of the material was found to be 450°C by thermogravimetric analysis, indicating that the mate...

Embodiment 3

[0062] Based on the electrochemical performance test of the lithium-sulfur battery using the squaraine-based organic porous polymer material as the active material of the present invention:

[0063]The three kinds of sulfur / squaric acid-based organic porous composite materials prepared in Examples 1-2 were assembled with the lithium negative electrode to form a button battery. Table 1 is the electrochemical cycle performance test of the lithium-sulfur battery based on the sulfur / squaric acid-based organic porous composite material of the present invention under the condition of an electrochemical rate of 0.1 C, respectively. During the test process, the charge and discharge Coulomb efficiency of the battery can be maintained. Above 97%, indicating that the battery device has good cycle stability. In addition, a set of CR2025 standard button batteries with the same assembly conditions using elemental sulfur powder as the positive active material (without adding squaraine-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com