Production process of alginate fiber postoperative rehabilitation underpants and underpants produced through same

A seaweed fiber and production process technology, applied in the textile field, can solve the problems of insufficient toughness and strength, decreased antibacterial effect, damage to seaweed, etc., achieve hygroscopicity and breathability, softness, enhance antibacterial performance, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

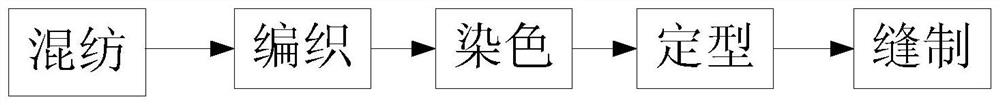

[0028] Such as figure 1 , figure 2 Shown, a kind of production technology of seaweed fiber postoperative rehabilitation underwear comprises the following steps:

[0029] 1. Blended

[0030] Select 1.5D*38mm seaweed fiber, blend it with long-staple cotton yarn with 37mm micronaire value of 4.2, and blend it into 60 cotton yarns through cleaning, combing, drawing, roving, spun yarn, twisting and other processes, of which seaweed fiber The content is 16%, and the cotton content is 84%.

[0031] Seaweed fibers have a high level of comfort over long-staple cotton, and feel similar to silk and cashmere. Coupled with its excellent antibacterial, anti-mildew, and biodegradable properties, it is suitable for making close-fitting knitwear. However, seaweed fibers are mostly staple fibers and cannot be directly woven into underwear. The tenacity and strength of seaweed yarn can be improved by blending seaweed fiber and long-staple cotton yarn into blended yarn through a series of pr...

Embodiment 2

[0048] A production process of seaweed fiber postoperative rehabilitation underwear, comprising the steps of:

[0049] 1. Blended

[0050] Select 1.5D*38mm seaweed fiber, blend it with long-staple cotton yarn with 37mm micronaire value of 4.2, and blend it into 60 cotton yarns through cleaning, combing, drawing, roving, spun yarn, twisting and other processes, of which seaweed fiber The content is 20%, and the cotton content is 80%.

[0051]In order to match the elasticity and toughness of high-count cotton, the spandex draft ratio in the covered yarn is set at 2.5-2.7. The use of antibacterial nylon yarn can enhance the antibacterial performance of the product.

[0052] 2. Weaving

[0053] Put the blended cotton yarn and nylon core-spun yarn in an environment of 20-25°C for more than 72 hours to ensure uniform texture after weaving. Thereafter, on the large circular knitting machine, under the conditions of 25-35° C. and relative humidity of 60-65%, the blended cotton yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com