Inducer for high-speed centrifugal pump and working method thereof

A high-speed centrifugal and inducer technology, which is applied in the field of inducers, can solve the problems that the inducer cannot meet the stability of the liquid flow at the inducer outlet at the same time, and achieve the effects of improving internal flow conditions, increasing the outlet head, and reducing wake vortices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

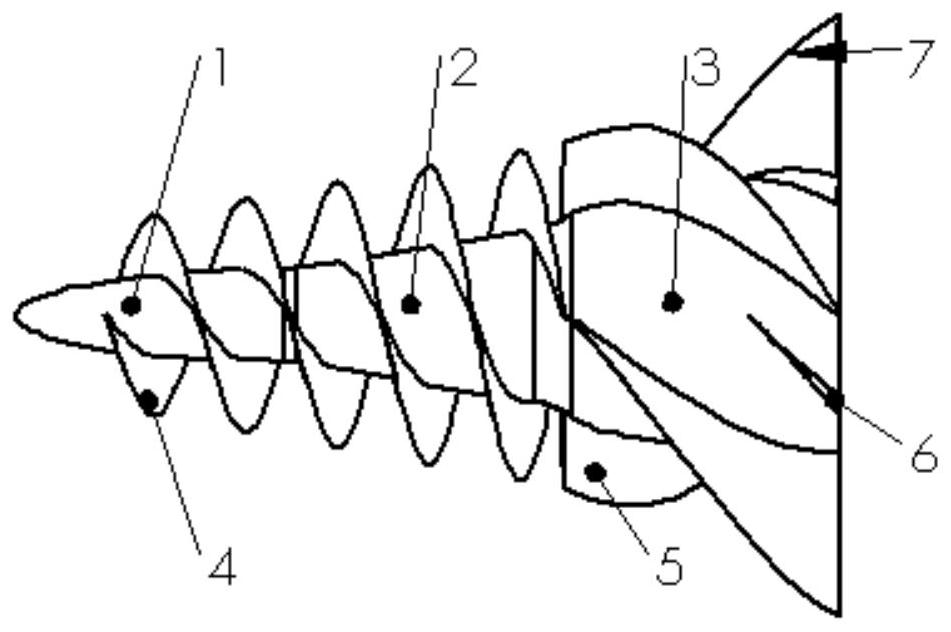

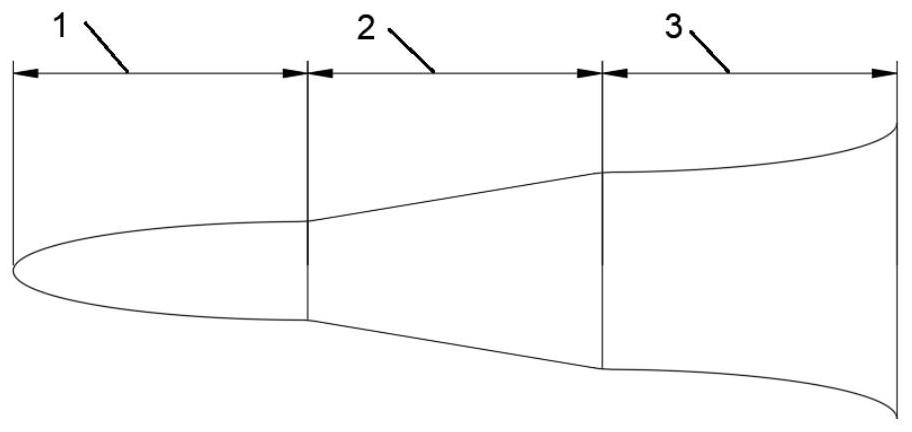

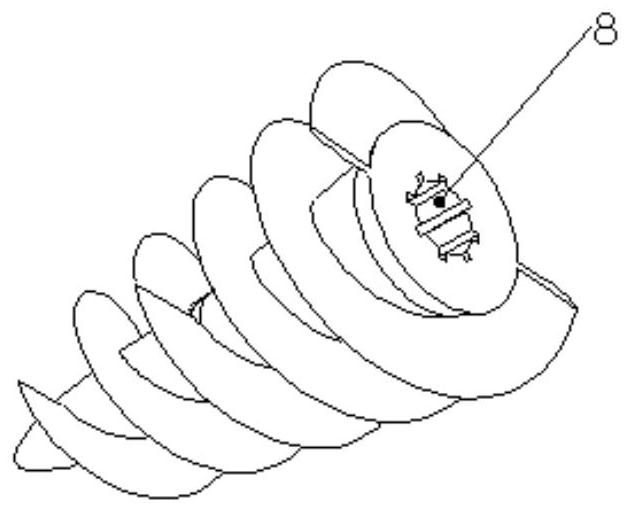

[0022] Such as figure 1 , 2 As shown in and 5, an inducer for a high-speed centrifugal pump is composed of a nonlinear variable curvature hub one 1, a linear hub two 2, a nonlinear variable curvature hub three 3, a main blade 4, a long tail splitter blade 5 and a short tail splitter blade 6 components; the nonlinear variable curvature hub 1 and the linear hub 2 2 are integrally formed; the linear hub 2 2 and the nonlinear variable curvature hub 3 3 are fixed; the nonlinear variable curvature hub 1 is based on a quarter convex ellipse The rotating body whose generatrix and curvature radius gradually increases along the direction from the nonlinear variable curvature hub 1 to the linear hub 2 2, the linear hub 2 2 is a rotating body with the oblique line as the generatrix, and the nonlinear variable curvature hub 3 3 is a quarter A rotating body whose inner concave ellipse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com