High-temperature-resistant gas-humidity reversal agent for improving recovery ratio of condensate gas reservoir as well as preparation method and application thereof

A gas-moisture reversal agent and technology for condensate gas reservoirs, which are applied in chemical instruments and methods, drilling compositions, etc., and can solve problems such as unsatisfactory gas-moisture reversal effect, failure to achieve strong air-humidity, poor temperature resistance, etc. problems, to achieve the effect of facilitating on-site promotion and application, easy preparation, and improved flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for preparing a high-temperature-resistant gas-humidity reversal agent that can be used to improve the recovery rate of condensate gas reservoirs, the steps are as follows:

[0060] (1) add 100g deionized water, compound emulsifier (sodium lauryl sulfate and polyoxyethylene octylphenol ether material ratio in the reactor that stirrer, temperature measuring equipment and reflux device are equipped with are 1: 1) 2g and 20g of methyl acrylate, and stirred for 25 minutes. Under the protection of nitrogen, the temperature was 30°C, high-speed stirring and emulsification for 40 minutes, and 0.53 g of sodium persulfate aqueous solution was added.

[0061] (2) Start oil bath heating, and keep it for 35 minutes when the temperature in the reactor rises and reaches 75°C. Add 1.12 g of sodium persulfate aqueous solution again, and after constant temperature reaction for 15 minutes, add perfluorooctyl ethyl acrylate, dodecafluoroheptyl methacrylate, methyl acrylate and p...

Embodiment 2

[0069] The preparation of the vapor-humidity reversal agent was as described in Example 1, except that the acrylate in steps (1) and (2) was changed to ethyl acrylate.

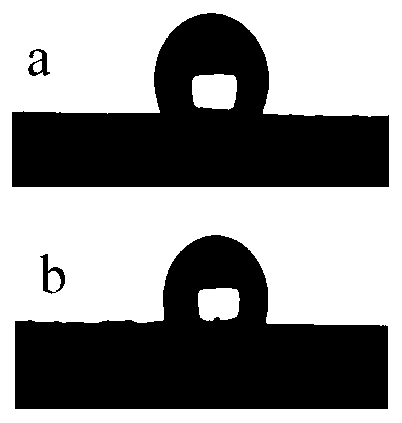

[0070] Mix the gas-moisture reversal agent prepared in this example with deionized water to make a 1.2% solution, use it to age the condensate gas reservoir rock for 28 hours, dry it at 100°C, take it out and let it stand at room temperature for 4 hours, and measure the After treatment, the contact angles of deionized water and n-hexadecane on the rock surface of condensate gas reservoirs are 124° and 108° respectively (such as image 3 shown).

Embodiment 3

[0072] The preparation of the vapor-humidity reversal agent was as described in Example 1, except that the acrylate in steps (1) and (2) was 2-methyl methacrylate.

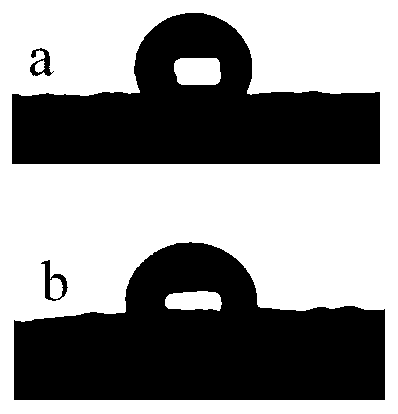

[0073] Mix the gas-moisture reversal agent prepared in this example with deionized water to make a 1.2% solution, use it to age the condensate gas reservoir rock for 28 hours, dry it at 100°C, take it out and let it stand at room temperature for 4 hours, and measure the After treatment, the contact angles of deionized water and n-hexadecane on the rock surface of condensate gas reservoirs are 127° and 95° respectively (such as Figure 4 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com