Drying and conveying mechanism for pesticide processing and production

A conveying mechanism and pesticide technology, applied in dryers, drying, drying of solid materials, etc., can solve the problems of increased production cost, low production efficiency, low transmission efficiency, etc., to improve production efficiency and improve discharge efficiency. , The effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

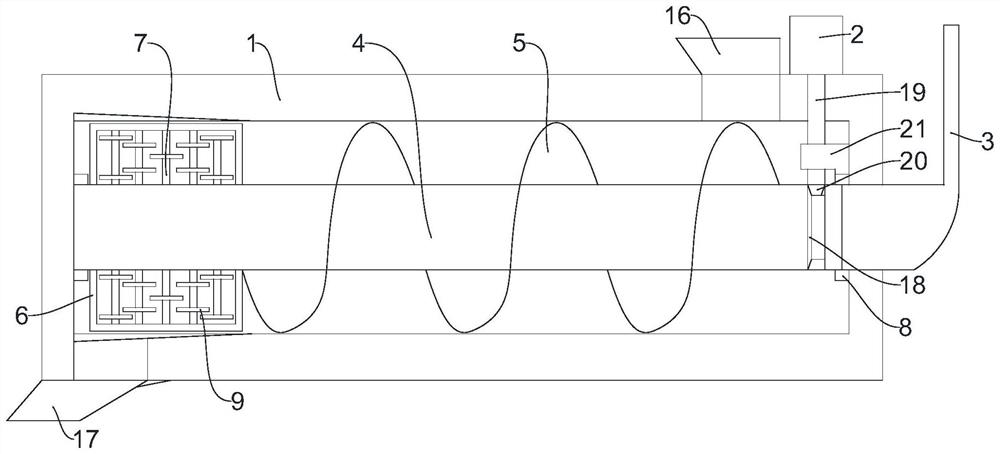

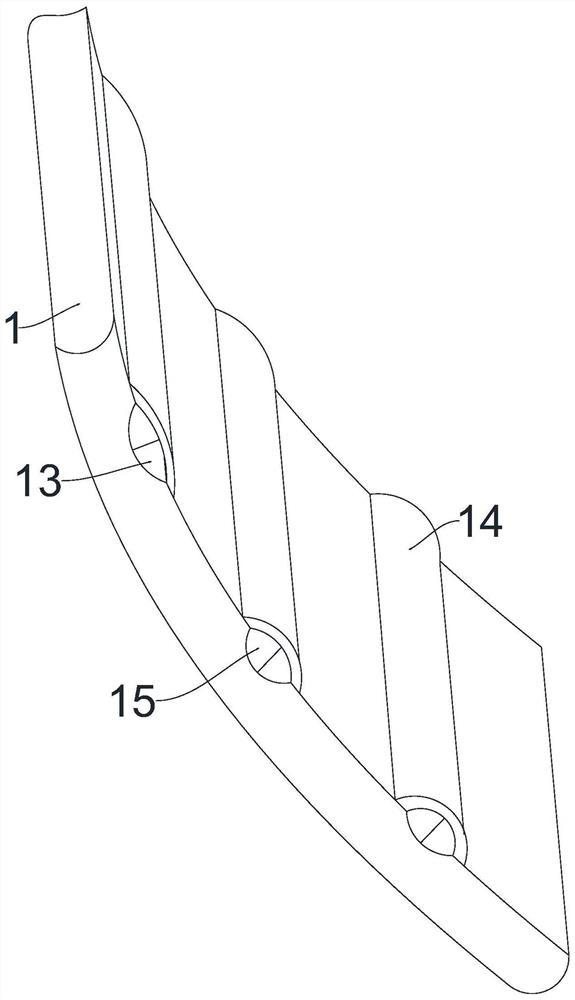

[0022] Embodiment: The vertical drive motor 2 is purchased from the market, and the high-temperature air intake pipe 3 is supplied with air through an external high-temperature gas transmission pipe. The vertical drive motor 2 drives the horizontal drive shaft 4 to rotate, and the spiral structure is used to drive the blade 5 to drive the pesticide from right to left. Convey on the left, then utilize the pulverizing and cutting device to stir, and utilize the cutting blade 9 to pulverize the pesticide.

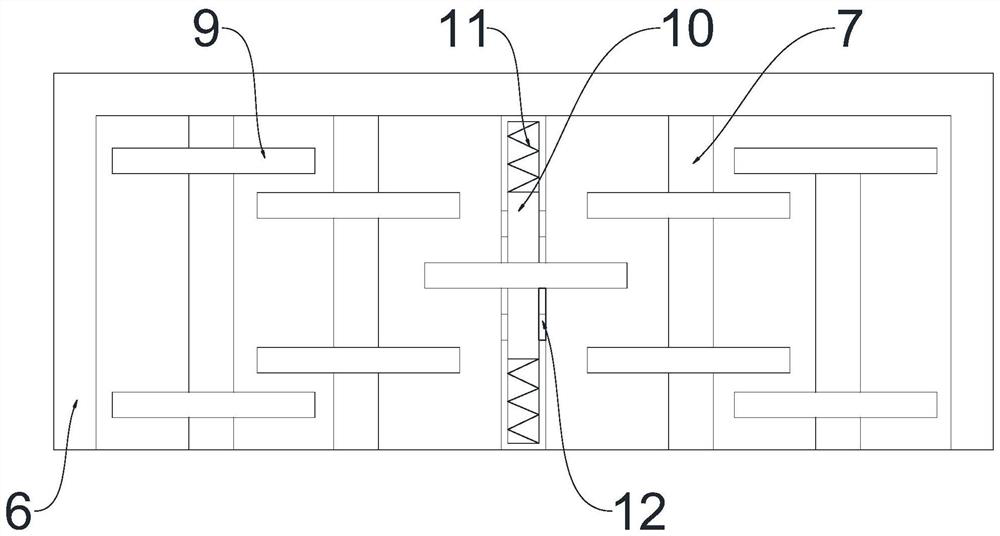

[0023] Further, in order to facilitate cutting, the crushing and cutting device includes a semicircular structure cutting blade 9 sleeved on the internal assembly rod 7, the internal assembly rod 7 is inserted with an internal telescopic block 10, and the internal assembly rod 7 is located inside the internal telescopic block 10 Extrusion springs 11 are installed on both sides, and the outer surface of the internal assembly rod 7 is provided with a lateral adjustment port 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com