A kind of fast stirring device for mine grouting material

A grouting material and mixing device technology, which is applied to cement mixing devices, mixers with rotary mixing devices, clay preparation devices, etc. The effect of fluidity, improving the mixing effect of materials, and improving the efficiency of stirring and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

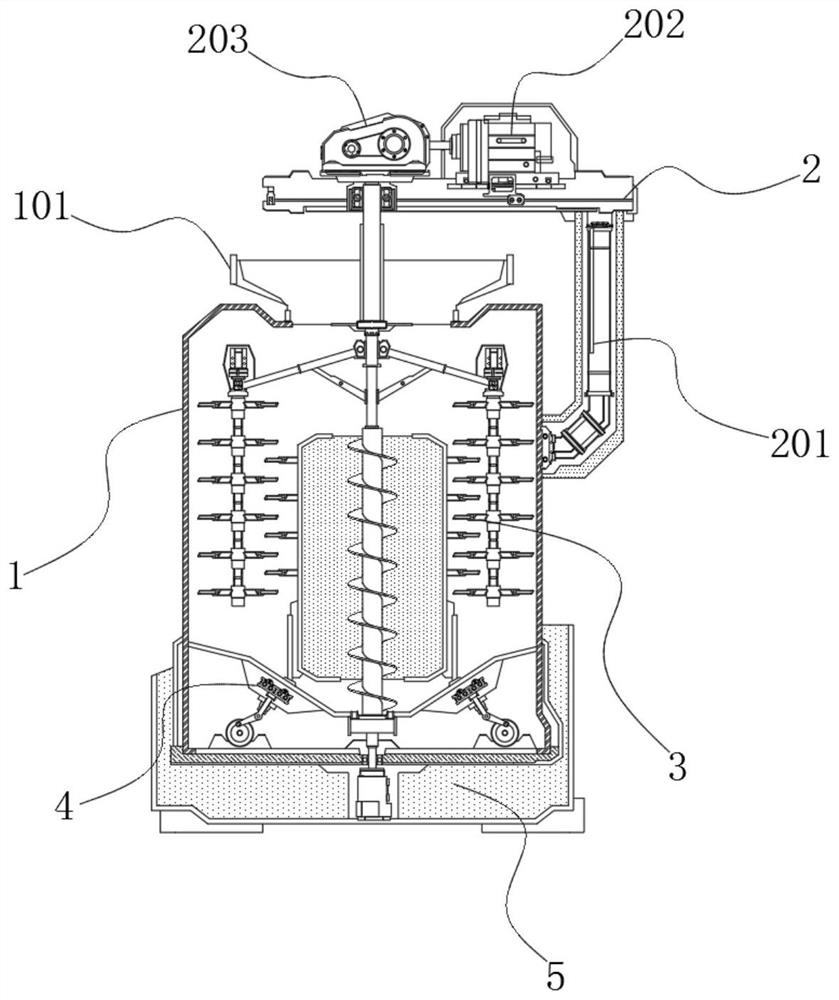

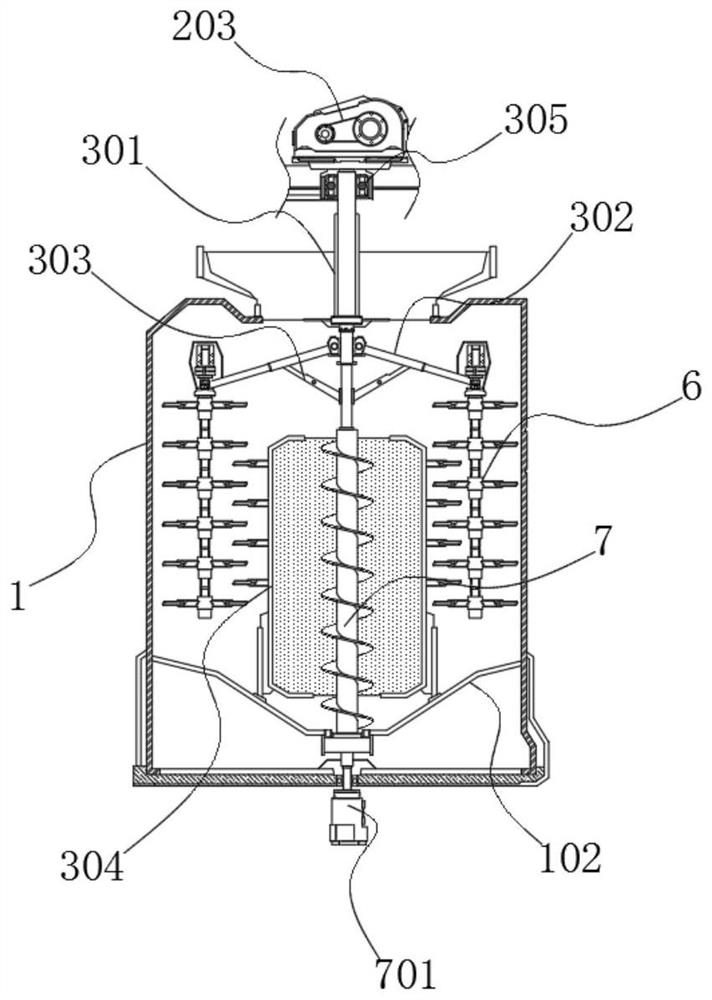

[0035] refer to figure 1 , the present invention provides a technical solution: a rapid mixing device for mine grouting materials, which includes a mixing drum base 1, a support base 5, an upper support frame 2, a feeding hopper 101, a stirring mixing assembly 3 and a vibrating feeding assembly 4. Among them, a mixing drum seat 1 is vertically arranged on the horizontally fixed support base 5, and a discharge port for discharging is provided on the side of the mixing drum seat 1, and the feature is that: the mixing drum seat 1 is an opening type cylinder structure, and its upper end surface is equipped with a feed hopper 101, the feed hopper 101 is used to send the grouting material into the mixing drum seat 1;

[0036] An upper support frame 2 is installed and fixed on the side of the cylinder wall of the mixing drum seat 1, and the cross section of the upper support frame 2 is an inverted L-shaped structure.

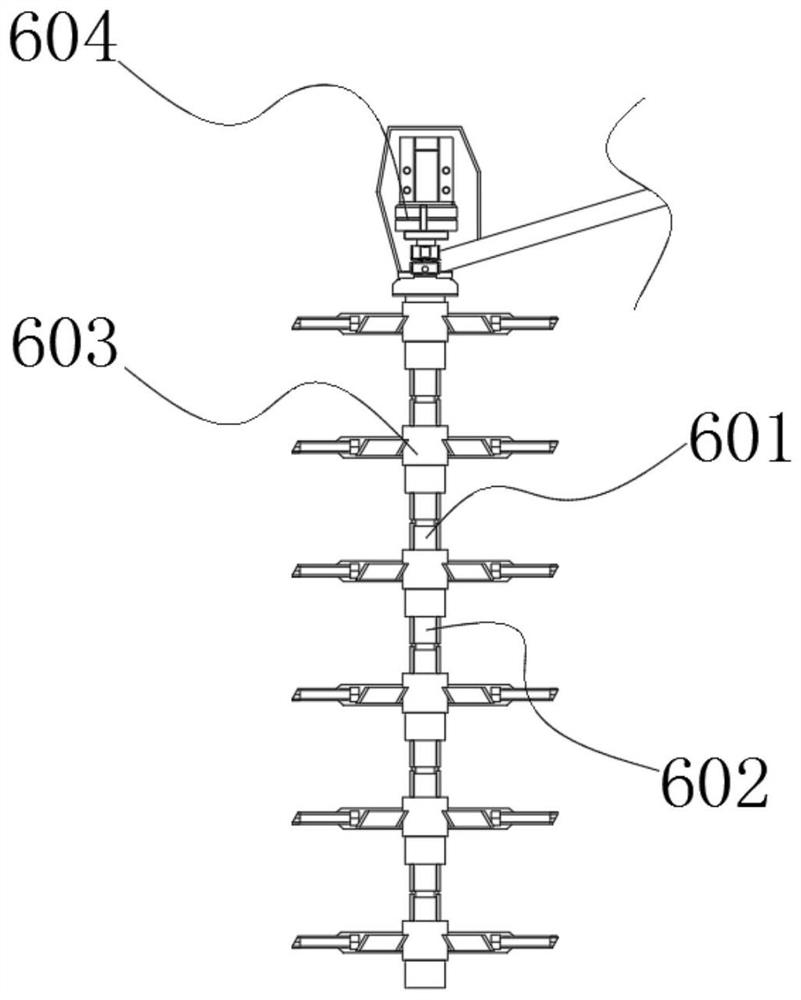

[0037] Moreover, a relatively rotatable stirring and mixing asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com