Large tractor link bearing structure

A tractor and bearing technology is applied in the field of large tractor tie rod bearing structure to achieve the effect of reducing friction coefficient and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

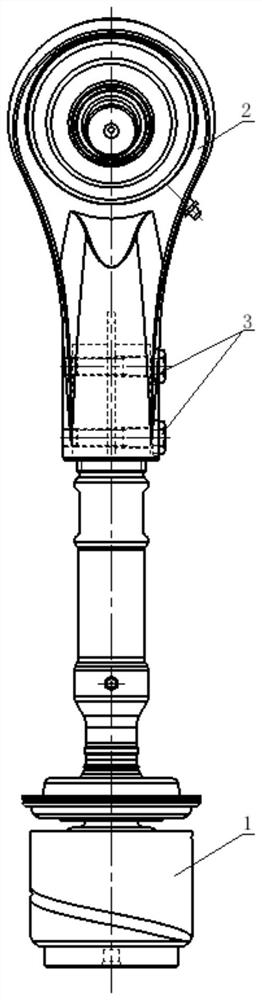

[0036] Such as figure 1 As shown, a large tractor tie rod bearing structure includes an inner tie rod bearing 1, an outer tie rod bearing 2 and a bolt 3. The ball pin rod of the inner tie rod bearing 1 extends into the thread inside the housing of the outer tie rod bearing 2 and is self-locking Slot, use bolt 3 to lock.

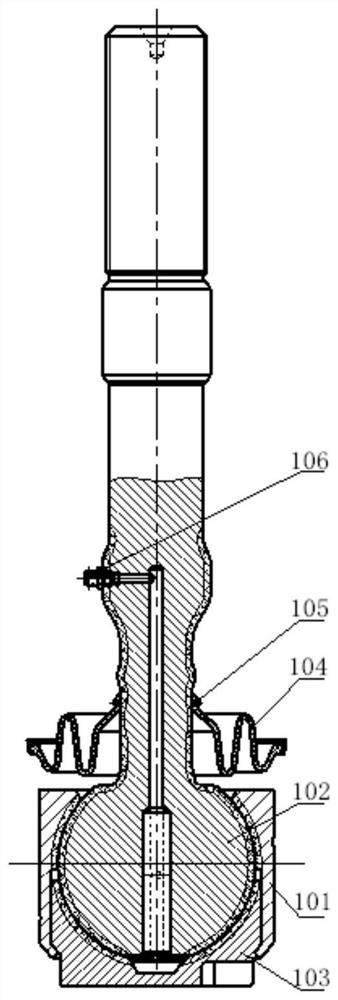

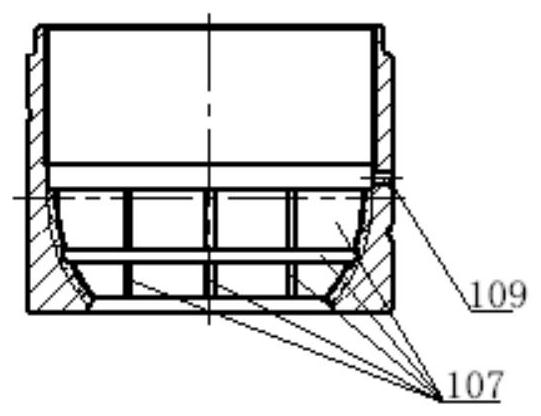

[0037] Such as figure 2 As shown, the inner tie rod bearing 1 includes a housing A101, a ball pin A102, a cover plate A103, a dust cover A104, a lock ring 105, a grease nipple A106, a lubricant A107, a lubricant B108, an oil hole 109 and an exhaust groove 110; The ball head part of the pin A102 is fitted into the housing A101 seat hole through clearance fit. The cover plate A103 is located at the bottom end of the housing A101. The outer diameter of the cover plate A103 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com