Raw material efficient crushing equipment for cosmetic essential oil production

A technology of crushing equipment and cosmetics, applied in chemical instruments and methods, filtration separation, presses, etc., can solve the problems of large labor consumption, high cost, poor crushing effect, etc., achieve less labor consumption, increase practicability, and crushing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

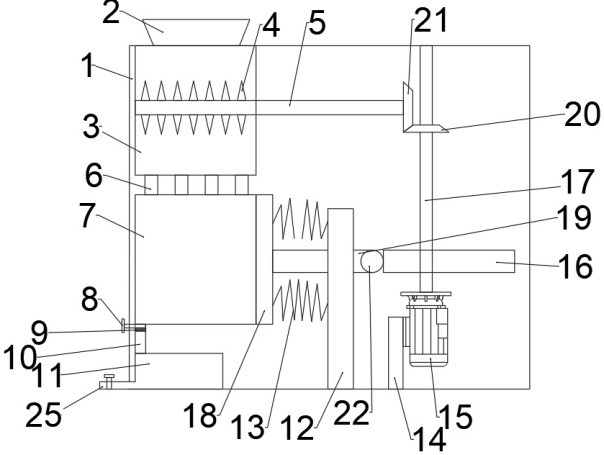

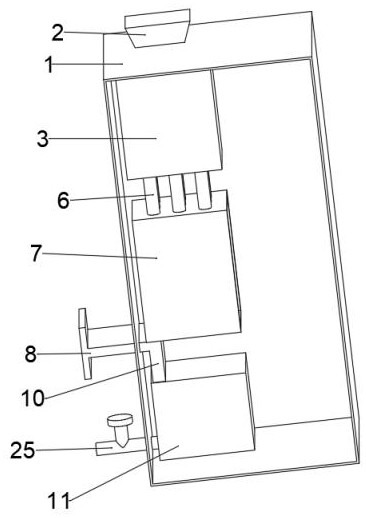

[0028] Reference Figure 1 ~ Figure 2 , A high-efficiency crushing equipment for the production of cosmetics essential oil, including a box body 1, the upper part of the box body 1 is bolted with a feed inlet 2, the upper part of the box body 1 is bolted to a crushing box 3, and the bottom of the crushing box 3 is bolted There are several transition pipes 6, one end of the transition pipe 6 away from the crushing box 3 is bolted to the compression box 7, the lower left side of the compression box 7 is bolted to a collecting pipe 10, and the end of the collecting pipe 10 away from the compression box 7 is bolted to the collecting pipe Box 11, a second fixing plate 14 is connected to the right side of the lower part of the box body 1 with a second fixing plate 14 bolts on the right side of the second fixing plate 14 is connected to a rotating motor 15 and the output shaft of the rotating motor 15 is connected to a rotating shaft 17, a rotating shaft 17 The upper shaft is fixed wi...

Embodiment 2

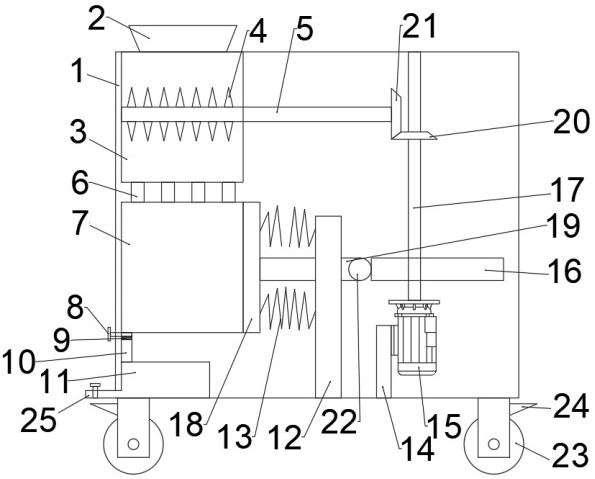

[0035] Reference image 3 , A kind of high-efficiency crushing equipment for the production of cosmetic essential oils. Compared with Example 1, this embodiment is provided with a walking mechanism under the box 1. The walking mechanism includes a rolling wheel 23 and a brake plate 24. The bottom four corners of the box 1 Both are bolted to the rolling wheel 23, and the rolling wheel 23 is bolted to the brake plate 24. The rolling wheel 23 allows the device to move freely, which facilitates the return and misappropriation of the device. The brake plate 24 is used to move the device to the designated position. Keep it stable so that it will not move during operation, ensure its purification effect and increase its applicability.

[0036] Working principle: The device can be moved freely by using the scroll wheel 23, which is convenient for the return and transfer of the device, and the brake plate 24 is used to keep the device stable when moving the designated position, so that it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com