Square tube roller device and square tube squaring machine applying same

A roll device and roll technology are applied in the field of steel pipe processing equipment, which can solve the problems affecting the forming quality of square pipes, difficult to meet the processing operations of square pipes of various sizes and specifications, and inability to adjust, so as to ensure the forming quality of square pipes and improve the quality of square pipes. The effect of forming quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

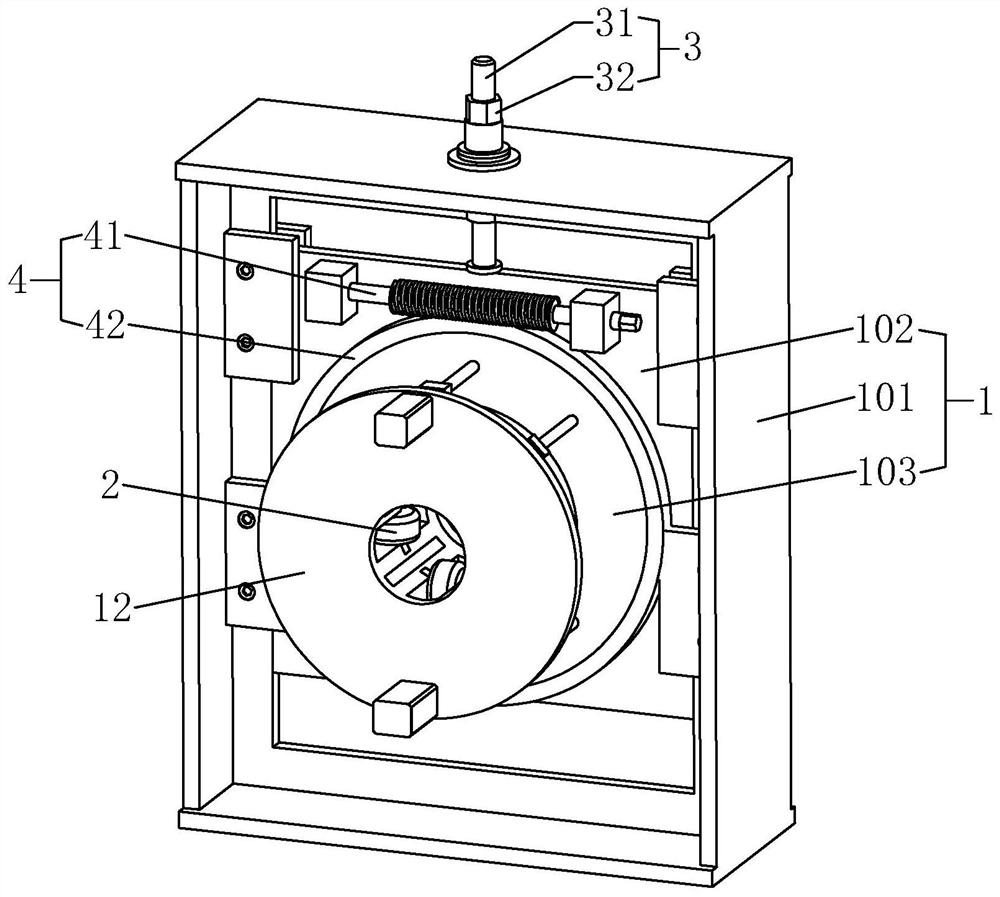

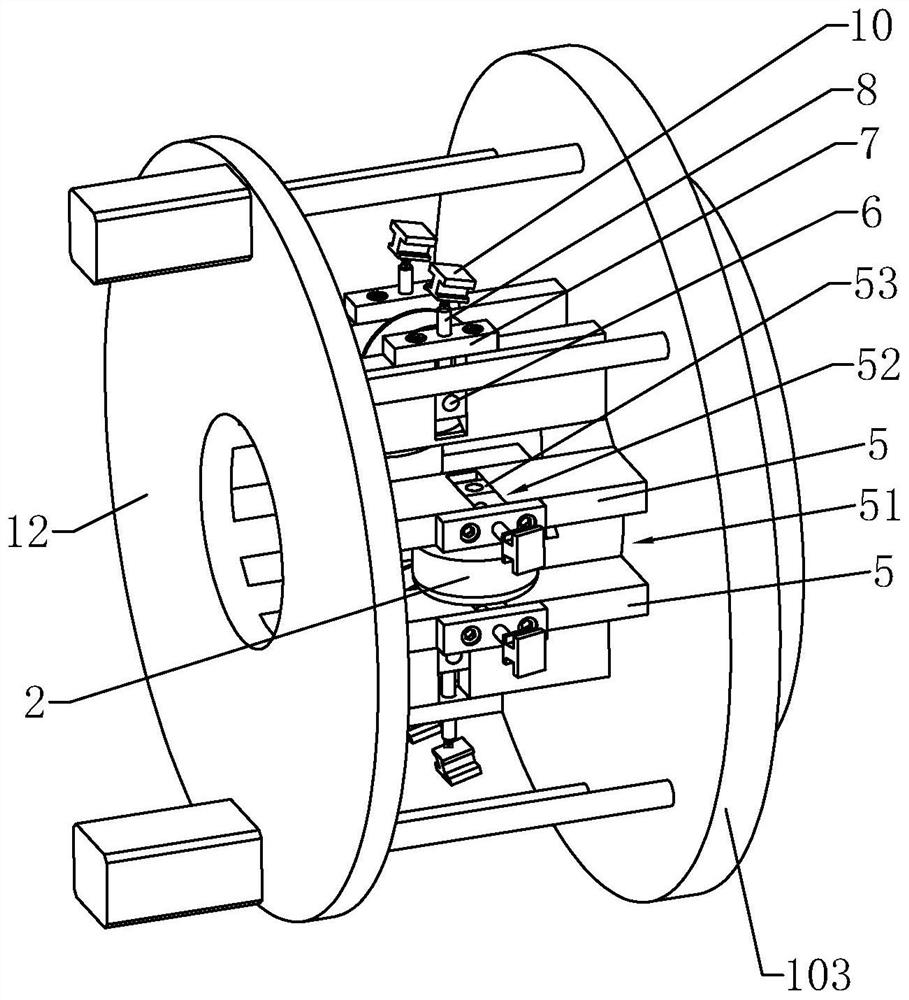

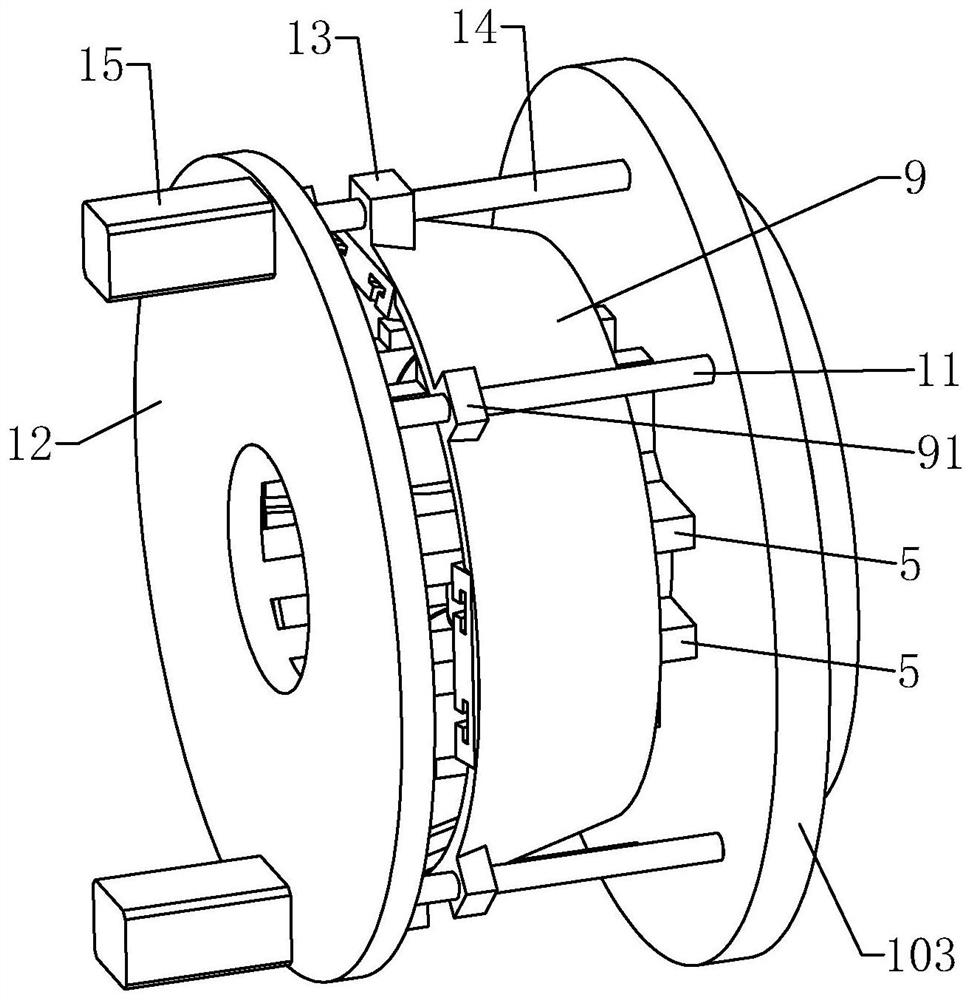

[0041] See attached Figure 1-2, a square tube roll device, comprising a mounting base 1, four sets of mounting components uniformly distributed on the circumference of the mounting base 1, each mounting component is respectively provided with a roll 2, each roll 2 is uniformly distributed around the circumference and the center Surrounded by a square hole. During work, the round pipe passes through the square hole under the traction of supporting equipment; each roll 2 carries out synchronous extrusion on the round pipe to realize the cold rolling forming of the square pipe.

[0042] Mounting seat 1 comprises the fixed seat 101 that is vertically arranged and is door-shaped structure, and fixed seat 101 interior is provided with movable seat 102 by sliding up and down through chute 52; height adjustment assembly3. Specifically, the height adjustment assembly 3 includes a threaded adjustment rod 31 that is vertically and movably worn on the top of the fixed seat 101. The low...

Embodiment 2

[0054] See attached Figure 5 , a square tube roll device, which is different from Embodiment 1 in that: the above-mentioned insert 17 is made of ordinary steel as a whole, and a wear-resistant layer 18 is provided on the side where the matching inclined surface 171 is located, and the wear-resistant layer 18 can adopt wear-resistant alloy material, to promote its service life.

Embodiment 3

[0056] See attached Figure 6-7 , the present invention also provides a square tube squaring machine, the square tube squaring machine comprises a machine platform 19, which is provided with several groups of above-mentioned square tube roll devices, and the tube roll devices of each side are along the length of the machine platform 19 Directions are set at even intervals. Specifically, taking any one of the square tube roll devices as an example, in order to install the square tube roll device, the upper side of the machine table 19 is provided with a positioning groove 191 extending along the width direction of the machine table 19; the bottom of the fixed seat 101 is embedded in the positioning groove 191 and form a slip fit with it.

[0057] At the same time, the upper side of the machine platform 19 is provided with a number of horizontal adjustment assemblies for adjusting the specific positions of the tube roll devices of each side. The adjustment seat 20 at the place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com