A birdcage automatic welding device

An automatic welding and birdcage technology, applied in welding equipment, resistance welding equipment, manufacturing tools, etc., can solve the problems of reduced work efficiency, easy soreness, labor, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

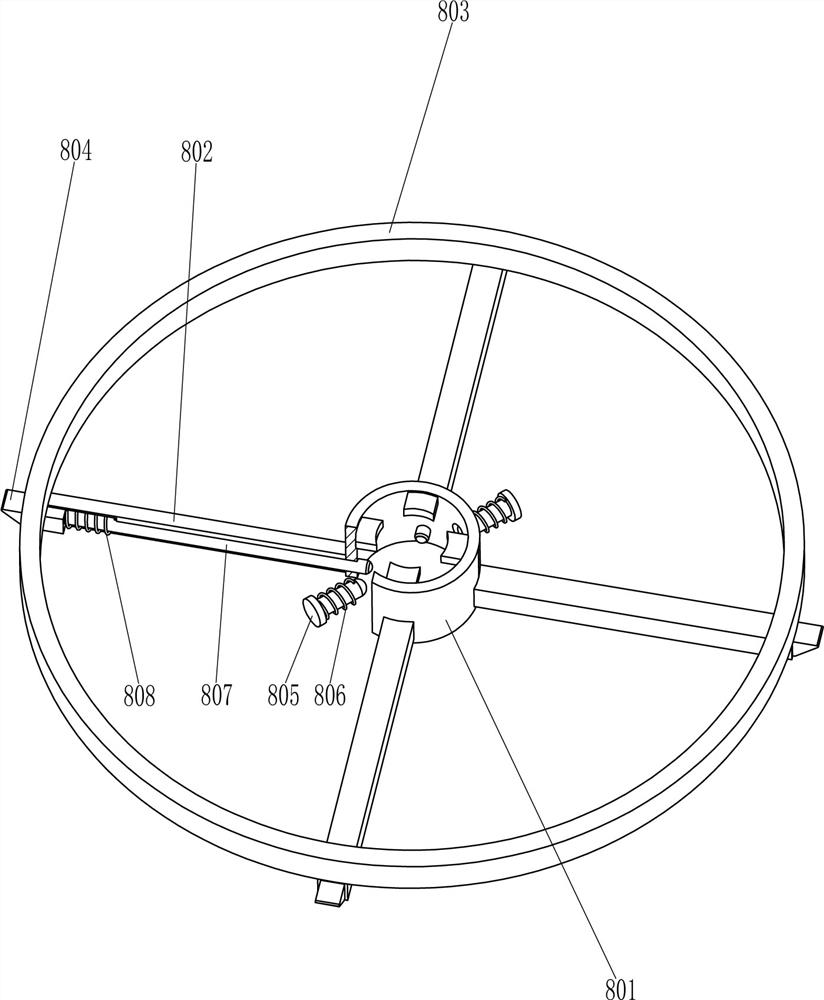

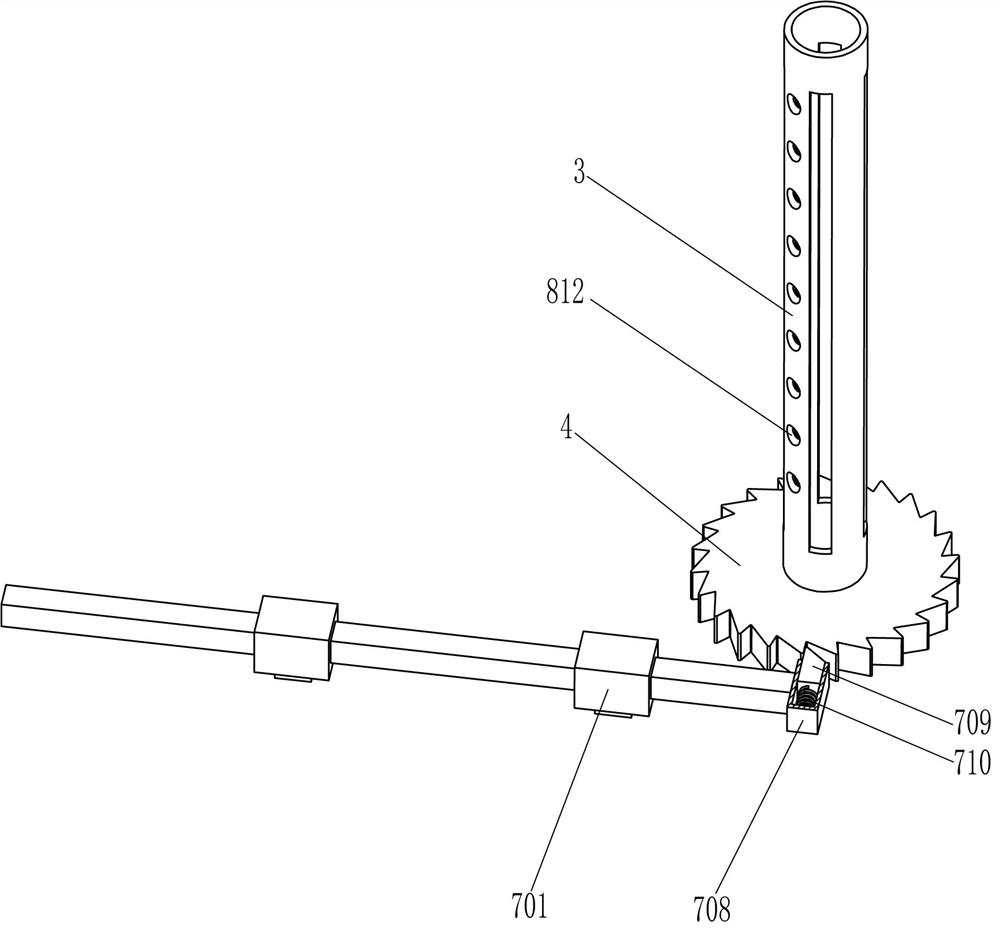

[0025] A birdcage automatic welding device, such as Figure 1-6 As shown, it includes a bottom plate 1, a support frame 2, a hollow shaft 3, a support plate 31, a ratchet 4, a guide sleeve 5, a welding assembly 6, a rotating assembly 7 and a support assembly 8, and the bottom left rear part of the top of the bottom plate 1 is fixed with a support Frame 2, guide sleeves 5 are fixedly connected to the upper, lower, and left sides of the inner rear side of the support frame 2, and a welding assembly 6 is provided between the guide sleeves 5 on the upper and lower sides and the inner side of the support frame 2, and the top right side of the bottom plate 1 is rotated in the middle. The hollow rotating shaft 3 is connected, and the rotating assembly 7 is arranged between the top and the front side of the bottom plate 1. The outer surface of the lower part of the hollow rotating shaft 3 is fixed with a ratchet 4 in the peripheral direction, and the ratchet 4 is in contact with the ro...

Embodiment 2

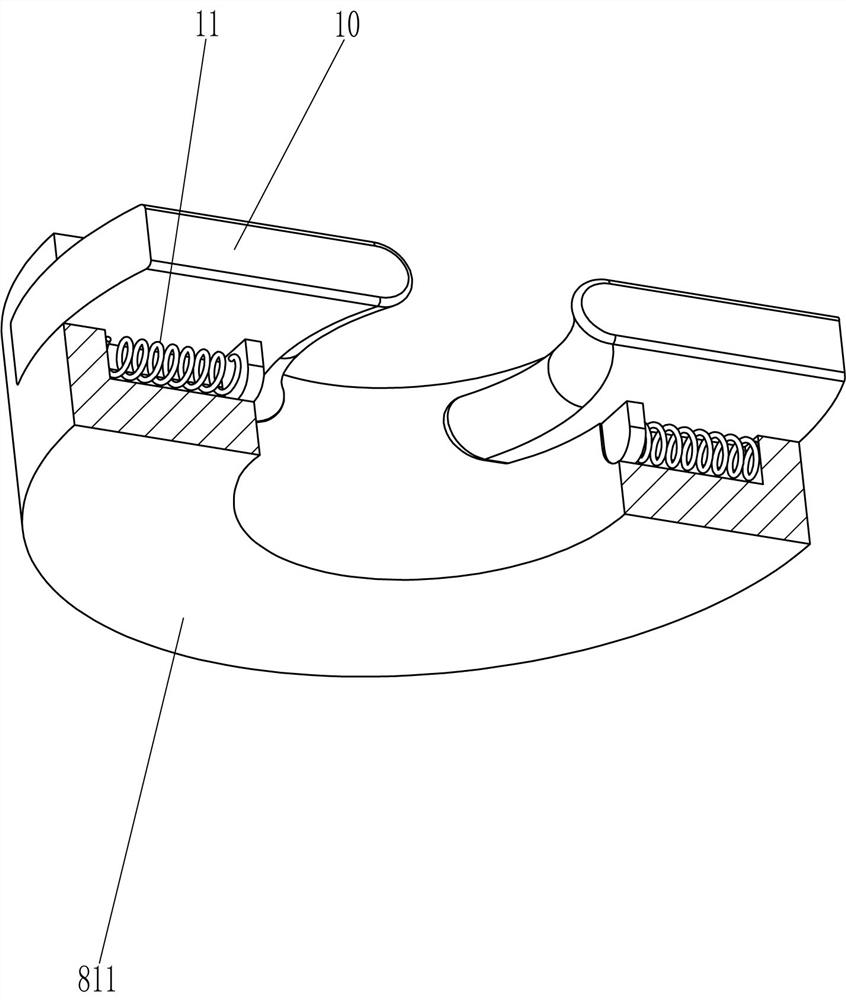

[0034] On the basis of Example 1, such as Figure 7 As shown, it also includes an extrusion block 10 and a ninth spring 11. The front and rear parts of the annular block 811 are slidably connected with the extrusion block 10. The extrusion block 10 cooperates with the special-shaped rod 809, and the inner side of the bottom of the extrusion block 10 A ninth spring 11 is connected with the inside of the ring block 811 .

[0035]When the operator pulls the special-shaped rod 809 to move upward, the upward movement of the special-shaped rod 809 drives the extruding block 10 to move outward, the ninth spring 11 compresses, and the extruding block 10 moves outward to contact the birdcage 9 to fix it. When the birdcage 9 is welded with the wire ring, the birdcage 9 is removed from the support plate 31, the birdcage 9 is separated from the extrusion block 10, and then the operator pushes the special-shaped rod 809 to move downward and reset, because the ninth spring 11 The role of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com