Bridge-cutoff aluminum alloy door and window manufacturing process

A technology for aluminum alloy doors and windows and a manufacturing process, applied in the field of broken bridge aluminum alloy doors and windows, can solve the problems of needing bolts, inconvenient assembly, unstable door and window frames, etc., and achieves the effects of high bonding strength, convenient assembly and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

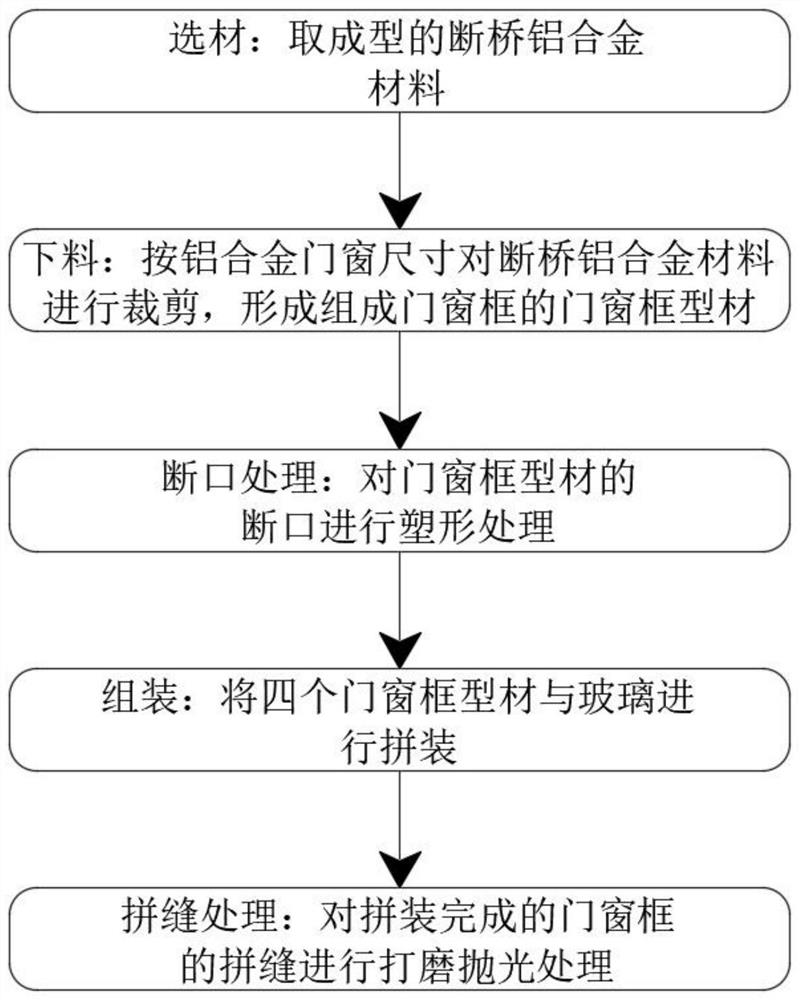

[0042] A manufacturing process of broken bridge aluminum alloy doors and windows, the specific process is as follows:

[0043] Material selection: take the formed broken bridge aluminum alloy material;

[0044] Cutting: according to the size of aluminum alloy doors and windows, the broken bridge aluminum alloy materials are cut to form the door and window frame profiles that form the door and window frames;

[0045] Fracture treatment: shape the fracture of door and window frame profiles;

[0046] Assembly: Assemble the four door and window frame profiles with the glass;

[0047] Seam processing: Grinding and polishing the seams of the assembled door and window frames.

[0048] The specific steps of fracture processing are as follows:

[0049] Heat and soften the two ends of the door and window frame profiles;

[0050] Insert the softened ends of the door and window frame profiles into the shaping mold for shaping, so that the two ends of the door and window frame profiles...

Embodiment 2

[0052] A manufacturing process of broken bridge aluminum alloy doors and windows, the specific process is as follows:

[0053] Material selection: take the formed broken bridge aluminum alloy material;

[0054] Cutting: according to the size of aluminum alloy doors and windows, the broken bridge aluminum alloy materials are cut to form the door and window frame profiles that form the door and window frames;

[0055] Fracture treatment: shape the fracture of door and window frame profiles;

[0056] Assembly: Assemble the four door and window frame profiles with the glass;

[0057] Seam processing: Grinding and polishing the seams of the assembled door and window frames.

[0058] The specific steps of fracture processing are as follows:

[0059] Heat and soften the two ends of the door and window frame profiles;

[0060] Insert the softened ends of the door and window frame profiles into the shaping mold for shaping, so that the two ends of the door and window frame profiles...

Embodiment 3

[0068] A manufacturing process of broken bridge aluminum alloy doors and windows, the specific process is as follows:

[0069] Material selection: take the formed broken bridge aluminum alloy material;

[0070] Cutting: according to the size of aluminum alloy doors and windows, the broken bridge aluminum alloy materials are cut to form the door and window frame profiles that form the door and window frames;

[0071] Fracture treatment: shape the fracture of door and window frame profiles;

[0072] Assembly: Assemble the four door and window frame profiles with the glass;

[0073] Seam processing: Grinding and polishing the seams of the assembled door and window frames.

[0074] The specific steps of fracture processing are as follows:

[0075] Heat and soften the two ends of the door and window frame profiles;

[0076]Insert the softened ends of the door and window frame profiles into the shaping mold for shaping, so that the two ends of the door and window frame profiles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com