An ultra-high-speed surface vehicle based on a three-stage supercavitating hydrofoil

A technology of supercavitation and aircraft, applied in the field of ships, can solve the problems of complex mechanism, increased cost and redundant equipment, etc., and achieve high lift, avoid natural cavitation phenomenon, and reduce mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

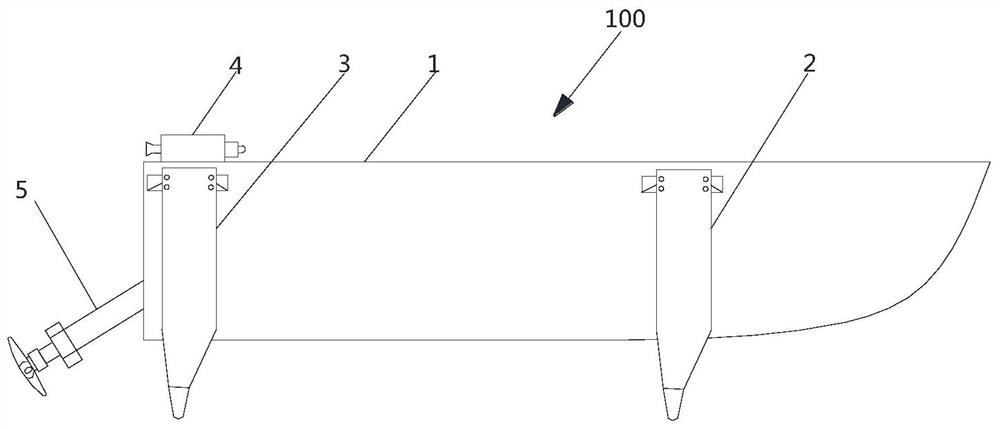

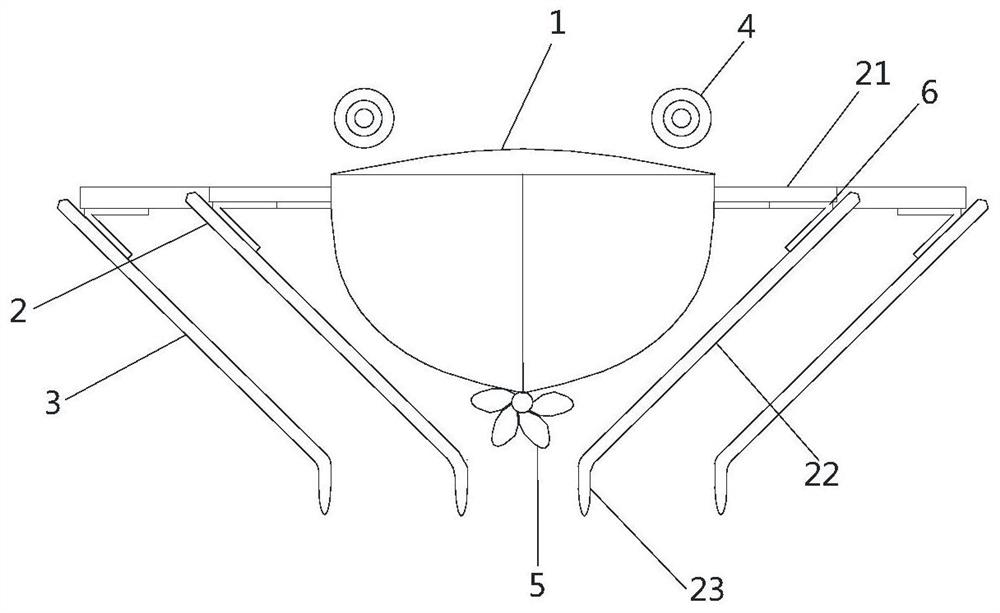

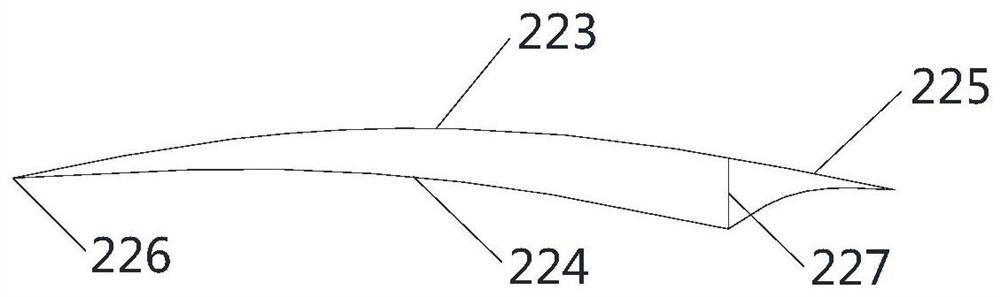

[0031] like figure 1 , 2 As shown, in one embodiment of the present invention, a super-high-speed water surface vehicle 100 based on a three-stage supercavitating hydrofoil is disclosed, which includes a ship body 1 of a round bilge type, and is installed on both sides of the front of the ship body 1 respectively. There are two symmetrical front hydrofoils 2, and the front hydrofoils 2 are connected to the main body 1 of the ship at a distance of one-third from the front end, and are close to the upper edge of the main body 1 of the ship; Horizontal flat wing 21, the oblique wing 22 that is connected to the other end of the flat wing 21 by one end and inclined to the ship main body 1 direction, and the vertical wing 23 that is connected to the other end of the oblique wing 22 and is perpendicular to the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com