Production and packaging process of bulb lamps

A packaging technology and bulb lamp technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of high production cost and low productivity, and achieve the effects of reducing the number of installation times, realizing automation and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

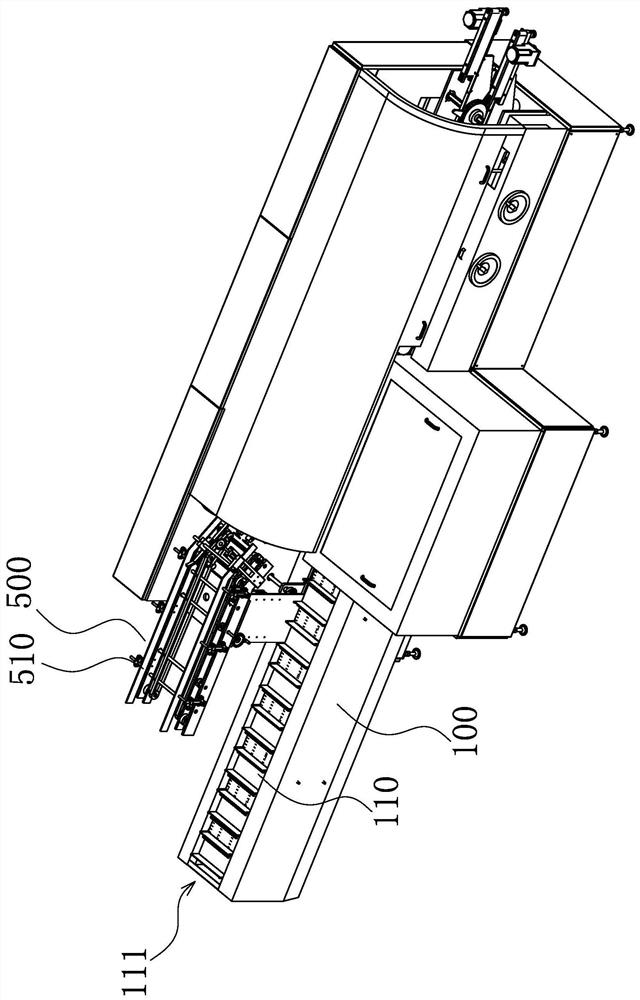

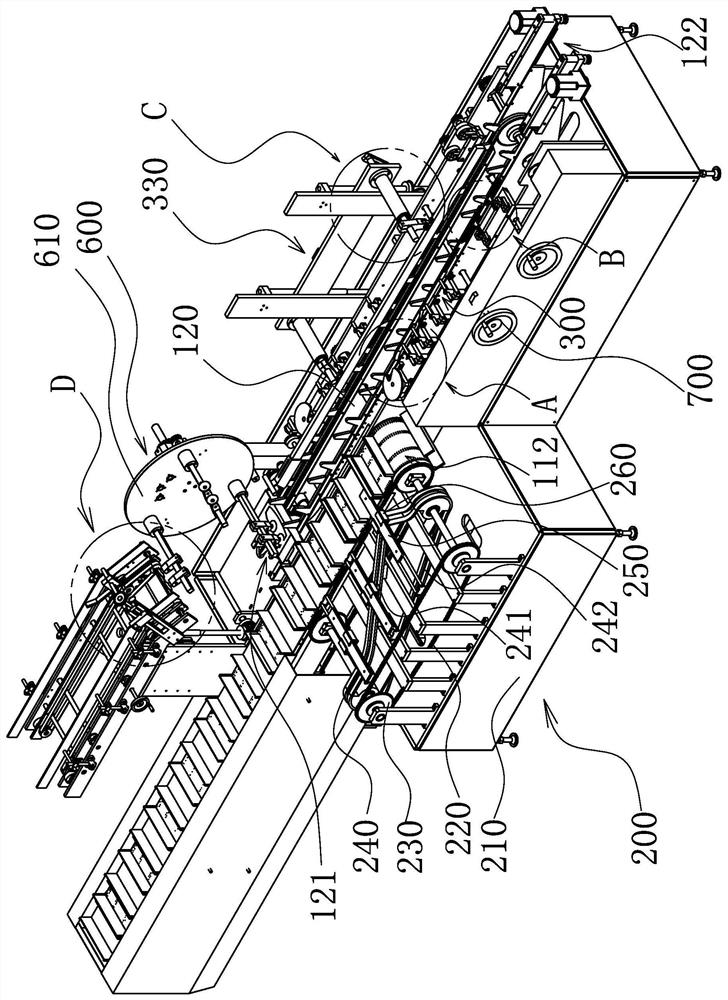

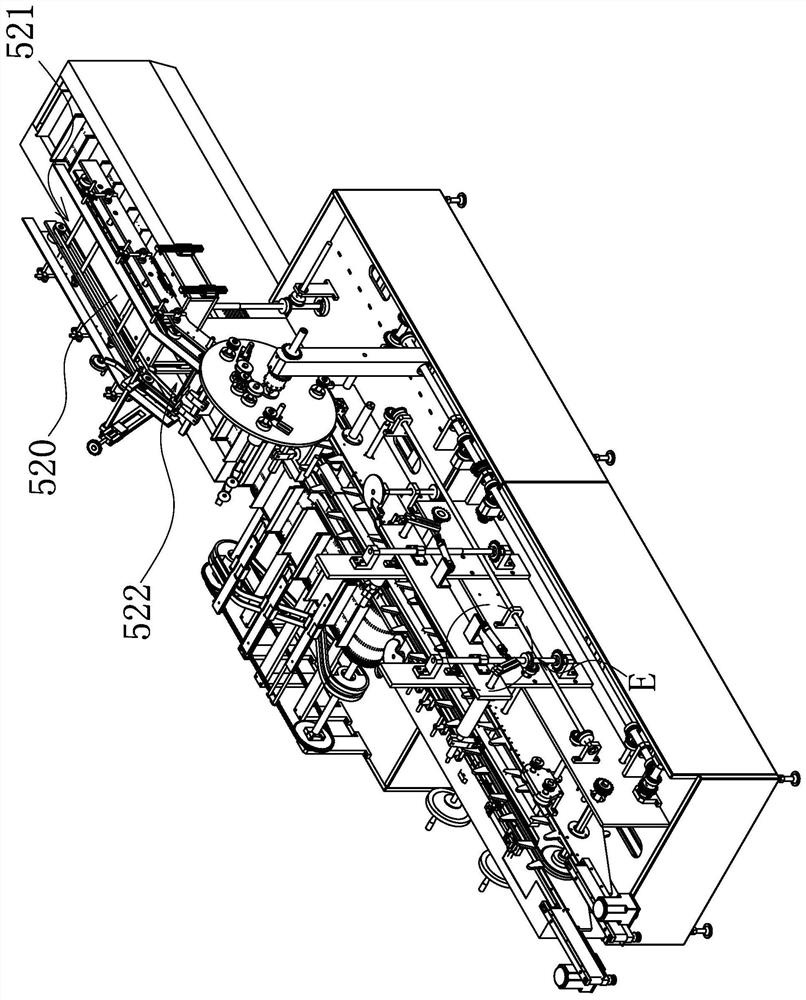

[0077] Such as Figure 1 to Figure 13 As shown, the production and packaging process of a bulb lamp provided by the present invention includes boxing equipment, and the boxing equipment includes: a frame 100, on which a first transmission channel 110 for transporting bulb lamps and The second transmission channel 120 for conveying the packaging box 400, and the two ends of the first transmission channel 110 are respectively the first feed end 111 and the first discharge end 112, and the two ends of the second transmission channel 120 are respectively the second Feed end 121 and the second discharge end 122, wherein, the first transfer channel 110 and the second transfer channel 120 are parallel to each other, and the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com