Quantitative packaging device for environment-friendly simple electronic cigarette atomizers

An electronic cigarette atomizer and quantitative packaging technology, applied in packaging, packaging machines, transportation packaging, etc., can solve the problem of reducing the workload of staff, and achieve the effect of automatic packaging, avoiding offset and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

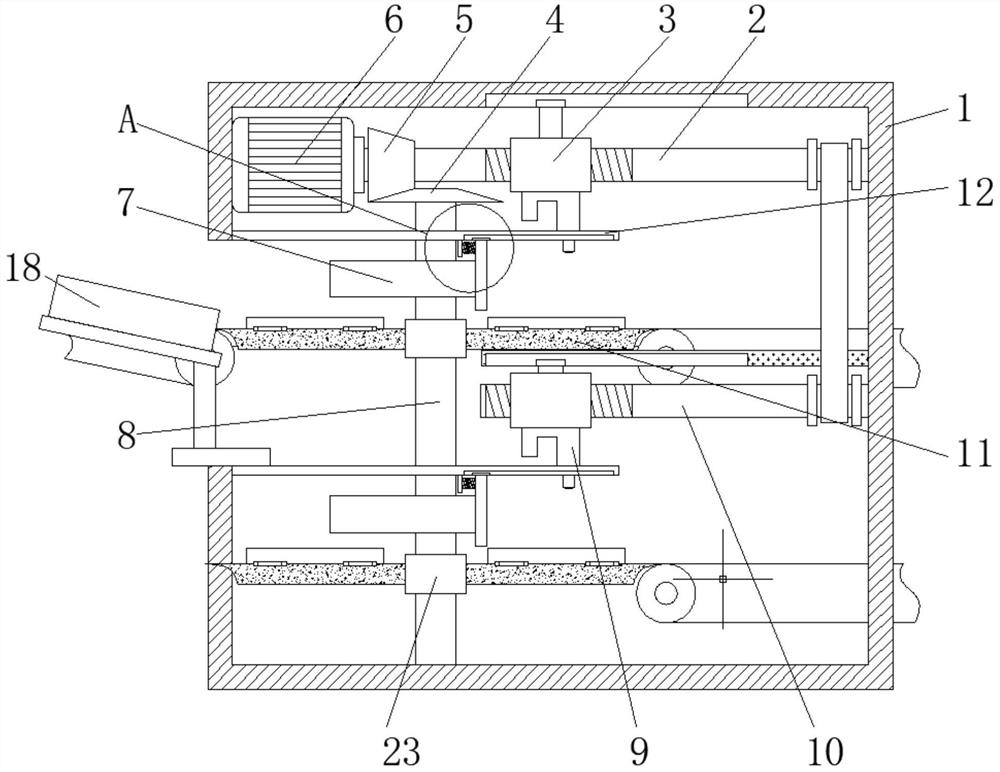

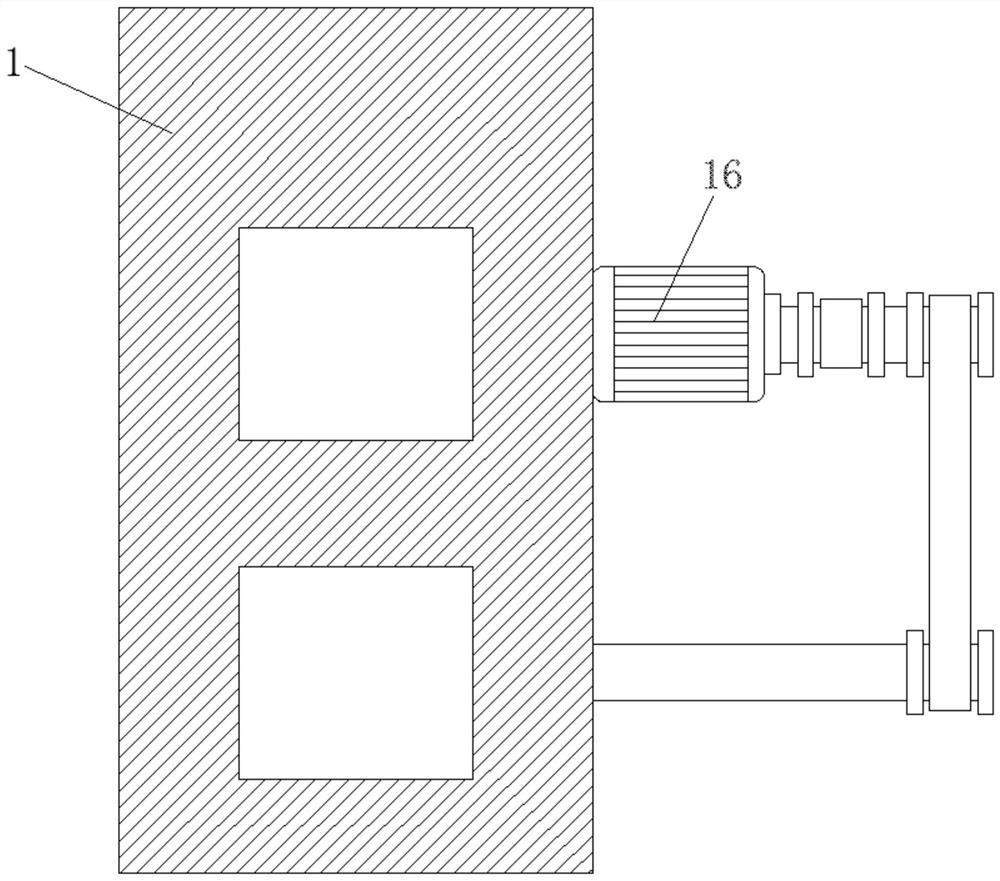

[0025] Embodiment 1: as figure 1 with Figure 5 As shown, the invention proposes a quantitative packaging device for an environmentally friendly and simple electronic cigarette atomizer. The worker places the packaged atomizer packaging box on the first conveyor belt, starts the biaxial motor 16, and the first box The back side of body 1 is fixedly connected with biaxial motor 16 by bolts, biaxial motor 16 starts and can make the 4th pulley rotate, and the 4th pulley rotates can make the 3rd pulley and the 5th pulley rotate, and the 3rd pulley rotating shaft can make the second rotating shaft Rotate, the rotation of the second rotating shaft can make the first conveyor belt rotate, the inner ring of the fixed sleeve 22 is sleeved with the second rotating shaft, the outer ring of the second rotating shaft is provided with the first conveyor belt, and the rotation of the first conveyor belt can make the atomizer packaging box enter into the On the first placement plate 11, the ...

Embodiment 2

[0026] Embodiment 2: as figure 1 with Figure 4 As shown, a moving contact piece is welded on the top of the movable column 17, and a fixed contact piece is welded on the side away from each other of the positive guide plate 18. When the atomizer packaging box deviates from the correct track, one end or a The side squeezes the positive guide plate 18, so that the fixed contact piece is in contact with the movable contact piece, and the side of the fixed column 21 close to each other is connected with a push rod motor 19 by bolts, so that the push rod motor 19 starts to work, and the push rod motor 19 to make the guide plate 18 relatively move, so as to guide the atomizer packing box and avoid the misalignment of the atomizer packing box.

Embodiment 3

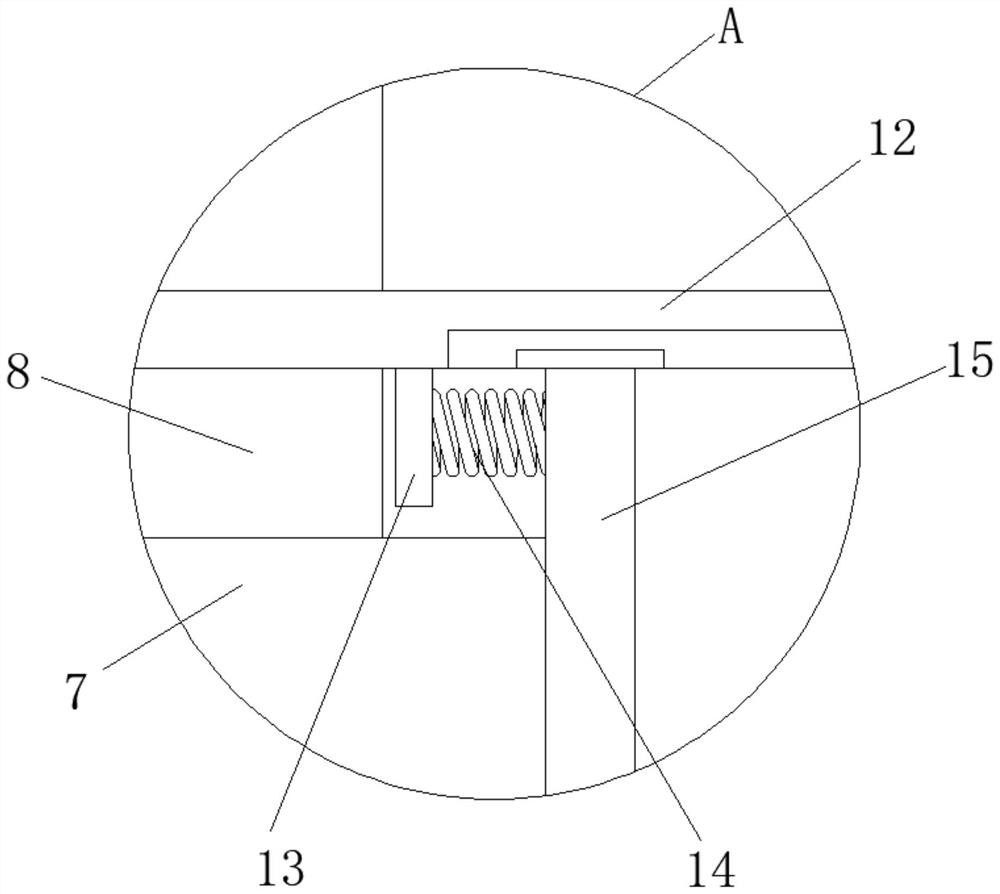

[0027] Embodiment 3: as figure 1 with Figure 5 As shown, the top of the left inner wall of the first box body 1 is fixedly connected with a drive motor 6 by bolts, the drive motor 6 is started, and the drive motor 6 can be started to make the first threaded rod 2 rotate, and the rotation of the first threaded rod 2 can make the second threaded rod 2 rotate. The bevel gear 5 and the first pulley rotate, the rotation of the first pulley can make the second pulley rotate, the rotation of the second pulley can make the second threaded rod 10, and the outer ring threads of the second threaded rod 10 and the first threaded rod 2 are all socketed There is a solenoid 3, the rotation of the second bevel gear 5 can rotate the first bevel gear 4 meshed with it, the bottom inner wall of the first box body 1 is connected with the first rotating shaft 8 in rotation, and the rotation of the first bevel gear 4 can make the first bevel gear 4 rotate. The rotating shaft 8 rotates, the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com