Material conveying device

A technology for conveying devices and materials, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of increasing equipment manufacturing costs, crushing, and reducing economic indicators of mining, so as to reduce the production of coal powder and improve the economy. Benefits, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In the following, only certain exemplary embodiments are briefly described. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the drawings and description are to be regarded as illustrative in nature and not restrictive.

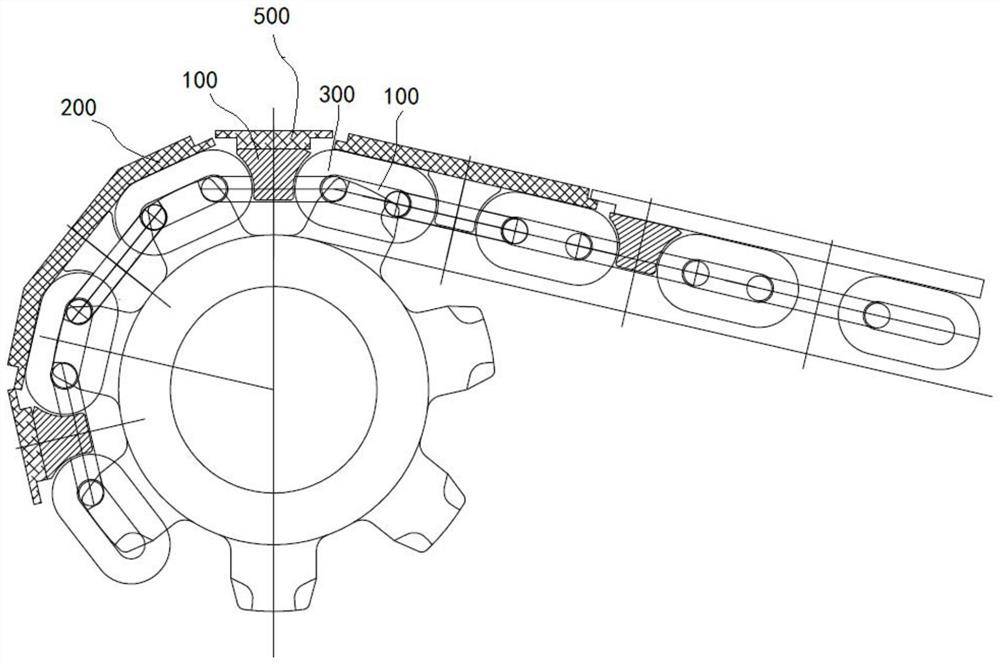

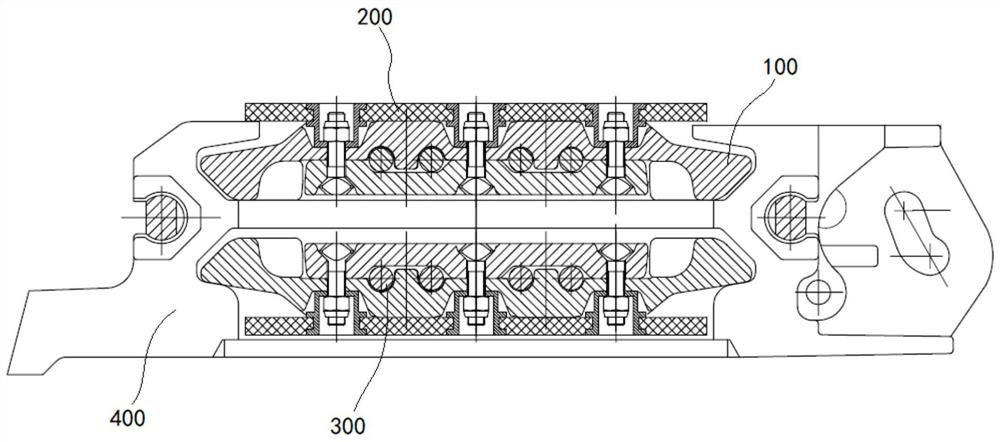

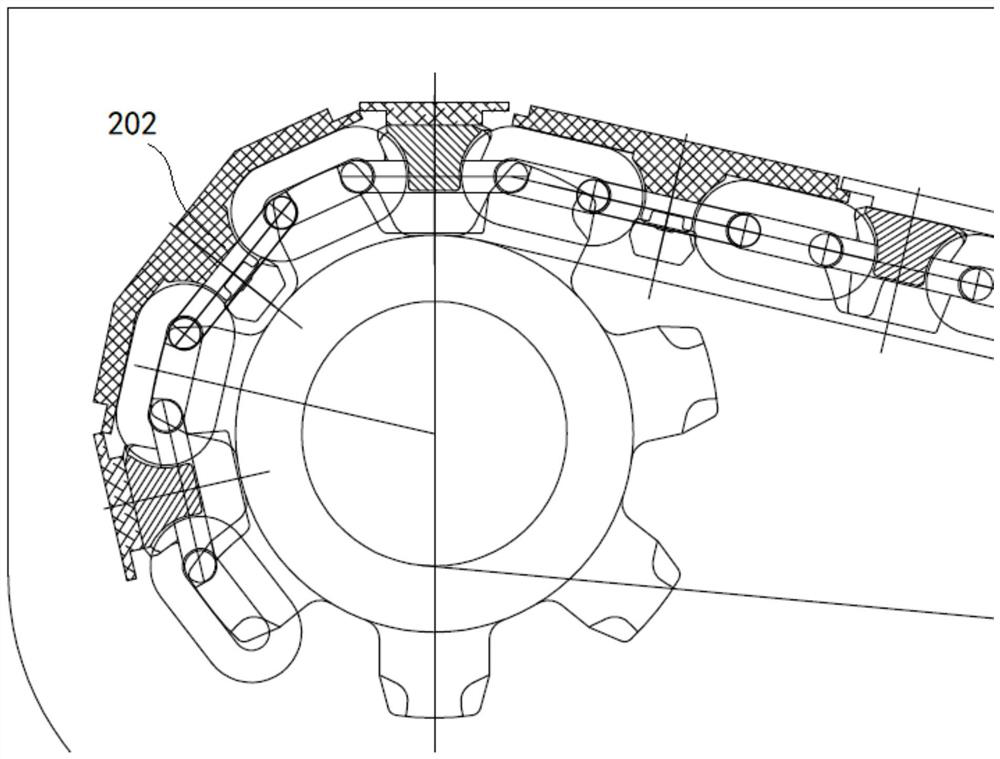

[0065] like figure 1 and figure 2 As shown, which shows a material conveying device, including:

[0066] The material conveying trough 400 has a running track; the track structure is, for example, a guide groove with a substantially uniform size or a guide structure fitted with each other, such as a slide rail provided with a slider with a slide groove. Another example is the track that matches the traveling wheel.

[0067] Loading and conveying components, including:

[0068] An endless chain 300 (a part is shown in the figure, in fact, the conveying trough has a support structure, which can allow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com