Automatic filler strip stacking device for panel stacks

A padding and board technology, which is applied in the field of padding devices for automatic stacking of boards, can solve the problems of high work intensity, low efficiency of stacking boards, large size, etc., and achieve the effect of improving stacking efficiency and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

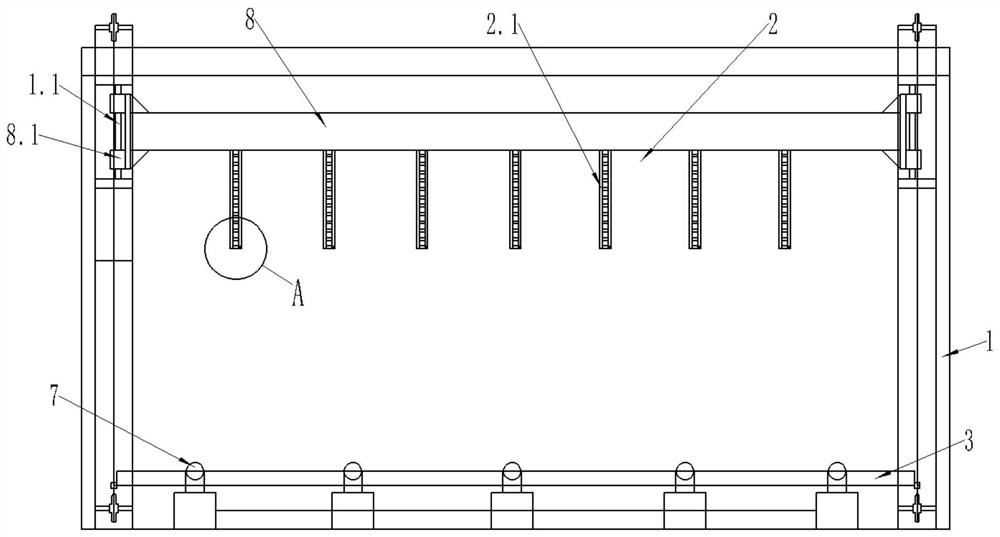

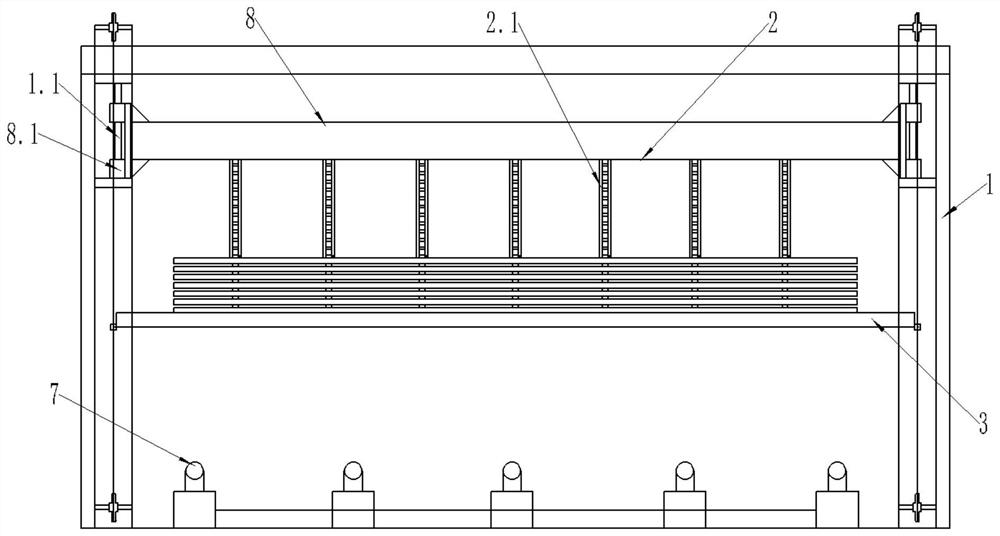

[0032] Such as Figure 1-5 As shown, a sheet material stacking automatic stacking pad device includes a frame 1, a pad storage bin 2 and a lifting platform 3 located on the frame 1, a pad release drive mechanism and a lifting platform drive mechanism; The pad storage bin 2 is used to store the pad; the pad release drive mechanism can drive the pad storage bin 2 to release the pad; the lifting platform 3 is located below the pad storage bin 2; the lifting platform The driving mechanism can drive the lifting platform 3 to translate up and down on the frame 1 .

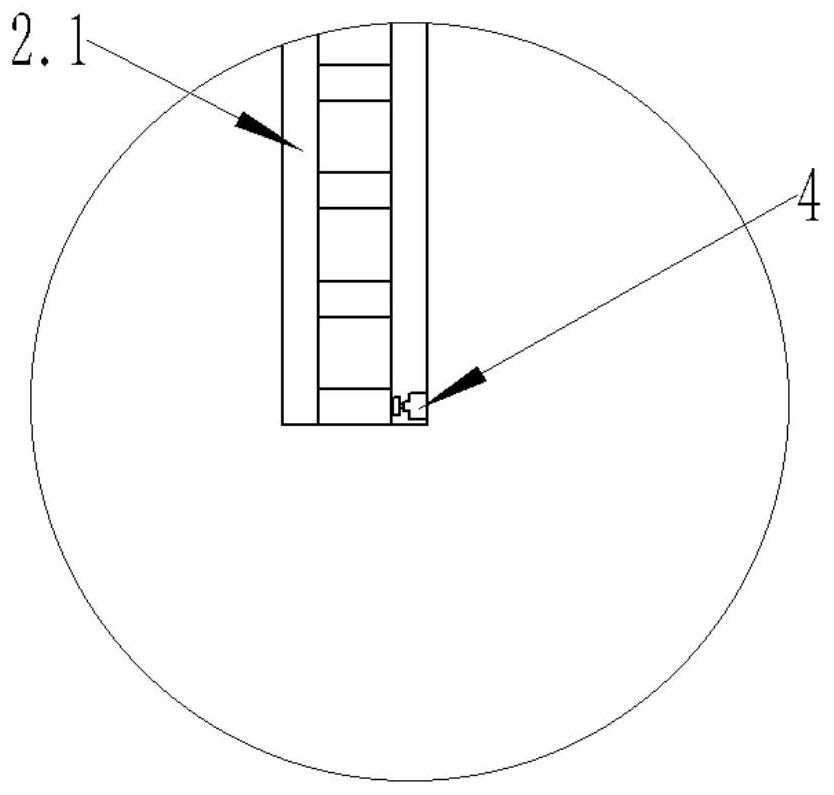

[0033] It also includes a crossbeam 8, the crossbeam 8 is arranged on the frame 1, and the pad storage bin 2 is installed on the crossbeam 8; the pad storage bin 2 includes at least 2 pad frames 2.1, the pad The number of strip frames 2.1 can be determined according to the actual length of the sheet material. If the length of the sheet material is longer, multiple strip frames 2.1 can be provided, and the length directi...

Embodiment 2

[0040] Different from Example 1, as Image 6 As shown, the driving mechanism of the lifting platform includes a sliding screw rod 5.2 and a bidirectional motor 6.2 arranged at the end of the sliding screw rod 5.2; there are four sliding screw rods 5.2, and the sliding screw rods 5.2 are symmetrically arranged in pairs The two ends of the lifting platform 3; the two ends of the lifting platform 3 are respectively connected with the sliding screw 5.2 through the screw slider, and the screw slider is threaded with the sliding screw 5.2.

[0041] Others are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com