Wafer moving mechanism, wafer electroplating unit and wafer electroplating equipment comprising same

A mobile mechanism and electroplating unit technology, applied in electrical components, circuits, electrolysis processes, etc., can solve the problems of wafer electroplating equipment with many components, high cost, and many process steps, and achieves solutions to production efficiency problems and equipment. The structure and manufacturing process are simple and convenient, and the effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

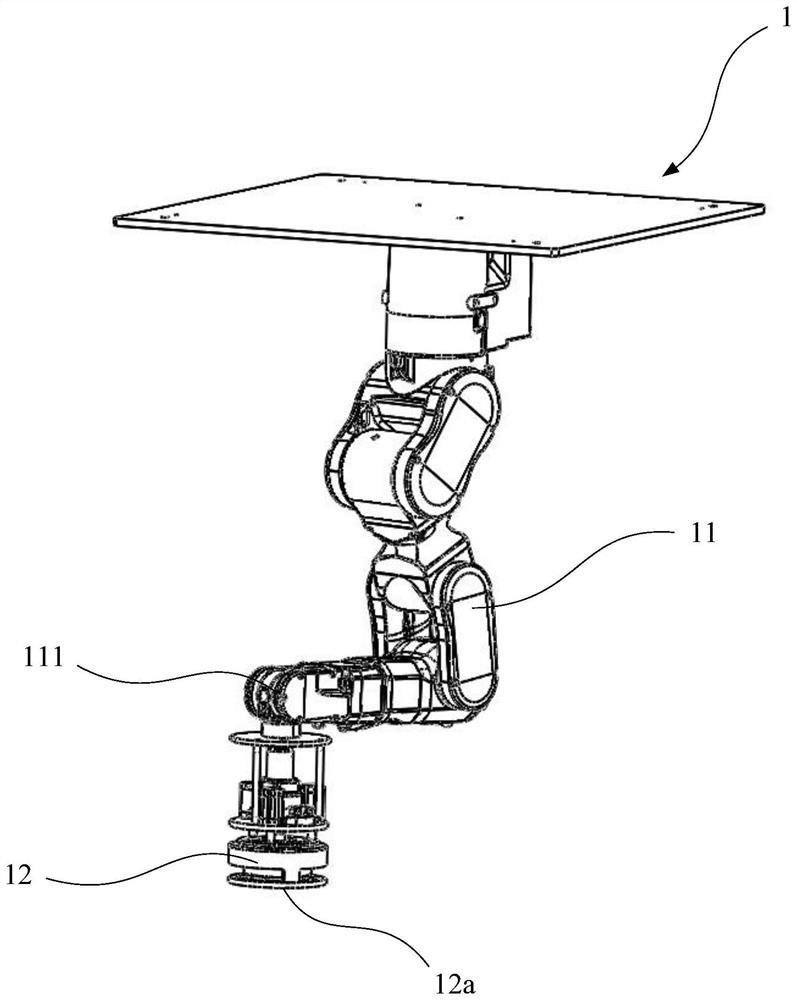

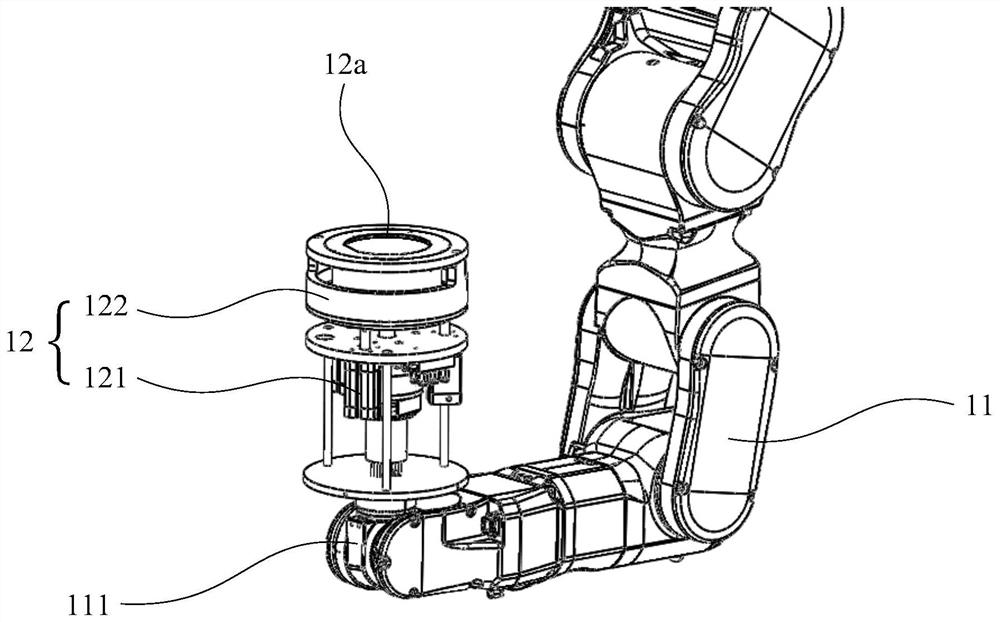

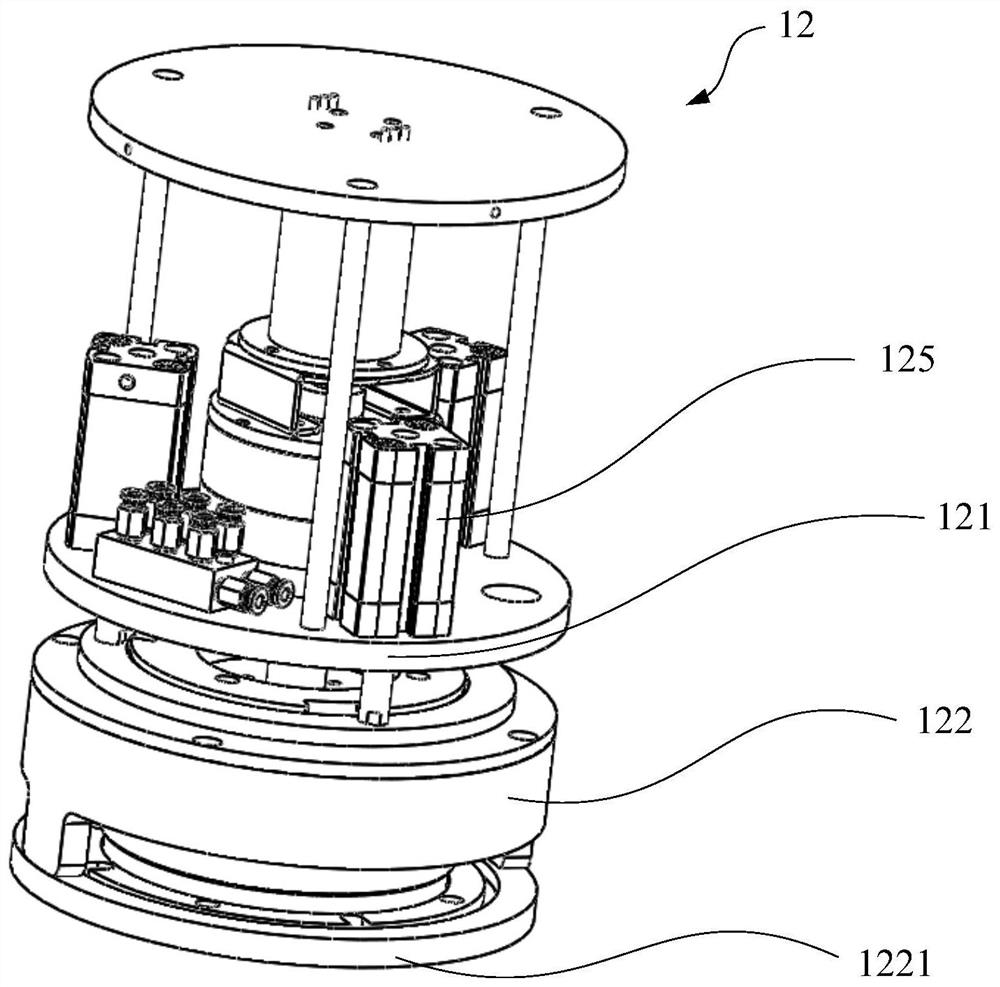

[0092] Such as figure 1 As shown, the present invention provides a wafer moving mechanism 1 , which includes a manipulator 11 and a wafer clamp 12 connected to each other. Wherein, the wafer holder 12 is used to fix the wafer, between the manipulator 11 and the wafer holder 12, the end of the manipulator 11 is connected on the wafer holder 12, and the manipulator 11 has at least three degrees of freedom, including lifting degrees of freedom, translation degrees of freedom and rotational degrees of freedom.

[0093] For the wafer moving mechanism 1, by setting the lifting degree of freedom and the degree of freedom of rotation on the manipulator 11 connected to the wafer holder 12, it is possible to drive the wafer holder 12 into and out of a certain working slot 2 and to drive the wafer holder 12 and The wafer 200 is rotated in the working tank 2 to meet the requirements of the electroplating process.

[0094] At the same time, by setting an additional translational degree o...

Embodiment 2

[0110] Such as Figure 6 As shown, the present invention also provides a wafer electroplating unit 10, the structure of which is roughly the same as that of the wafer electroplating unit 10 provided in Embodiment 1, except that the manipulator 11 of the wafer electroplating unit in this embodiment It is not a six-degree-of-freedom moving mechanism, and its horizontal degree of freedom can only move along the X-axis direction. It drives the wafer holder 12 along the X-axis direction (that is, along the Figure 6 The direction A) in the middle moves horizontally to achieve the purpose of transferring the wafer holder 12 between multiple working slots 2 . In this case, a plurality of working slots 2 should also be arranged along the above-mentioned horizontal direction A, so that the horizontal movement range of the manipulator 11 can cover these working slots 2 .

[0111] The degree of freedom setting of the manipulator 11 and the position setting of the working tank 2 can effe...

Embodiment 3

[0113] Such as Figure 7 As shown, the present invention also provides a wafer electroplating unit 10, which includes a wafer moving mechanism 1 and a plurality of working tanks 2, and the wafer moving mechanism 1 includes a manipulator 11 and a wafer clamp 12 connected to each other, and the wafer can be Being fixed on the wafer mounting surface 12a of the wafer holder 12, the manipulator 11 can transfer the wafer holder 12 between a plurality of work slots 2, thereby preventing the wafer from being placed in multiple different positions during the process of completing the electroplating process. The back and forth transfer between the manipulators 11 occurs, which effectively reduces the structural complexity of the wafer plating unit 10 .

[0114] In order to achieve the purpose of the manipulator 11 transferring the wafer holder 12 among multiple working slots 2 , the manipulator 11 in this embodiment should at least have degrees of freedom for lifting, translation and ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com