Heavy pouring and light pouring building with shell fabrication system and construction method

A system and architectural technology, applied in the direction of architecture, building structure, and building materials processing, can solve problems such as high construction costs, headaches in plumbing and electrical pipeline installation and equipment installation, and worrying about earthquake resistance, so as to meet individual needs Residential requirements, huge marketing potential, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

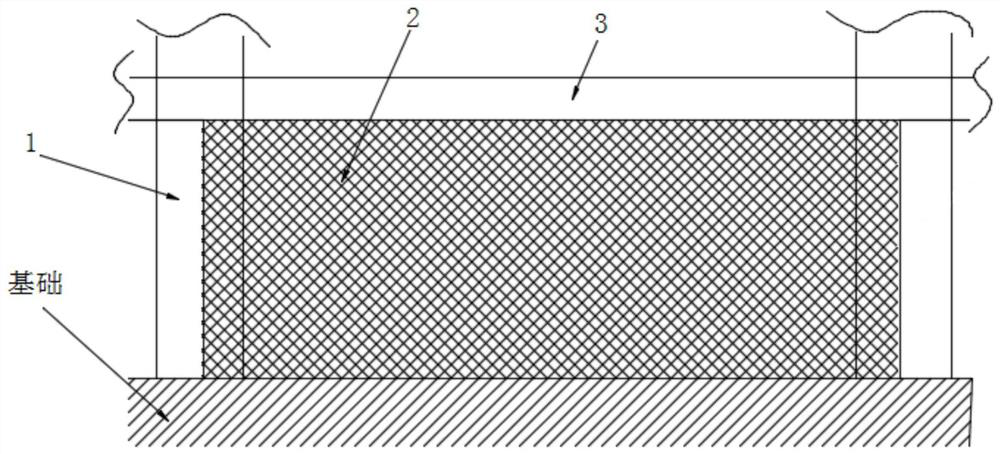

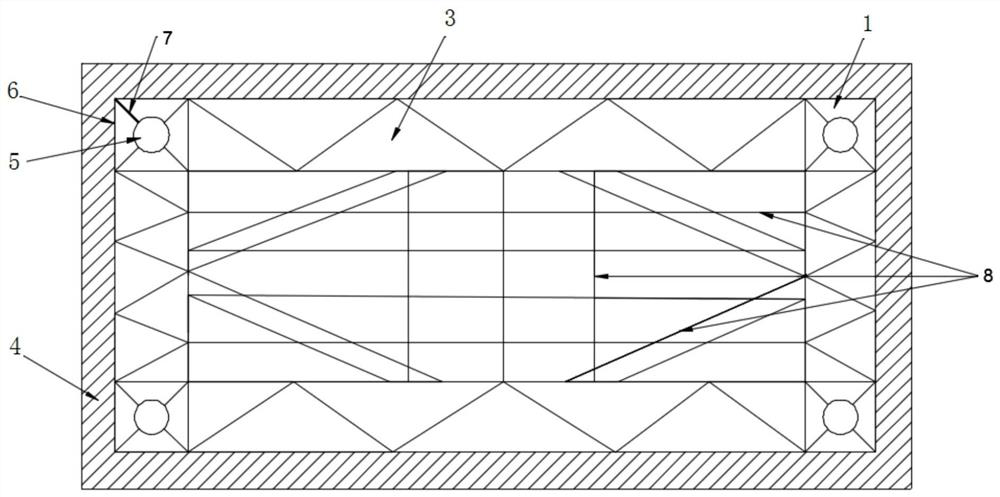

[0038] Such as figure 1 with figure 2 As shown, a heavy-casting-light-casting building with a shell assembly system includes hollow steel section columns I1, pull-out wall shell nets 2, steel truss beams 3 and prestressed floor slabs, and multiple hollow steel section columns I1 are connected end to end , and the hollow steel section column I1 located at the floor level is connected to the steel truss beam 3, the outer side of the steel truss beam 3 is provided with an insulation layer 4, the inner side of the steel truss beam 3 is connected to a prestressed floor, and two adjacent hollow steel sections A pull-out wall shell net 2 is arranged between the outer sides of the column I1, and the height of the pull-out wall shell net 2 is consistent with the height of the hollow steel section column. The insulation layer 4 is docked with the pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com