Automobile stamping and welding workshop fireproof alarm device and using method thereof

A technology of stamping welding and alarm devices, which is applied to fire alarms, separation methods, chemical instruments and methods that rely on smoke/gas effects, can solve the problems of panic, untimely alarm, and slow escape of the people present, and achieve Effects of increased sensing range, high connection efficiency, and low connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

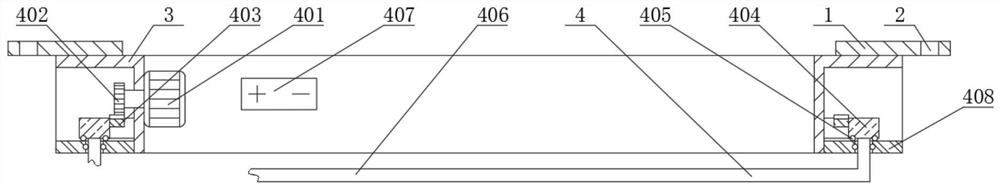

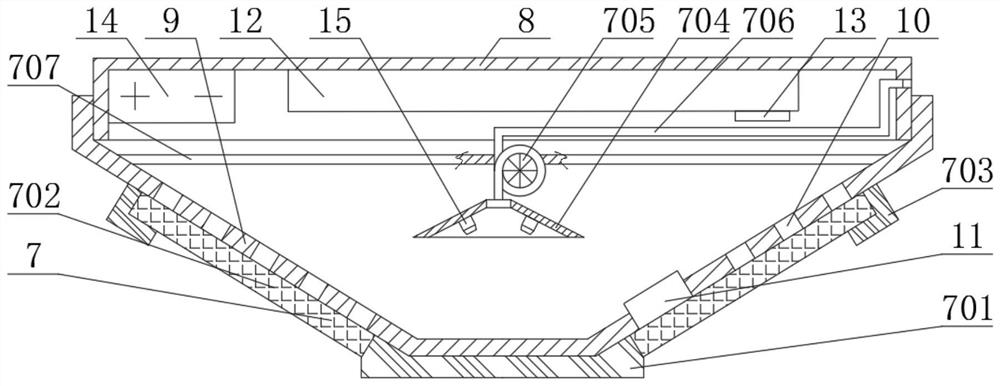

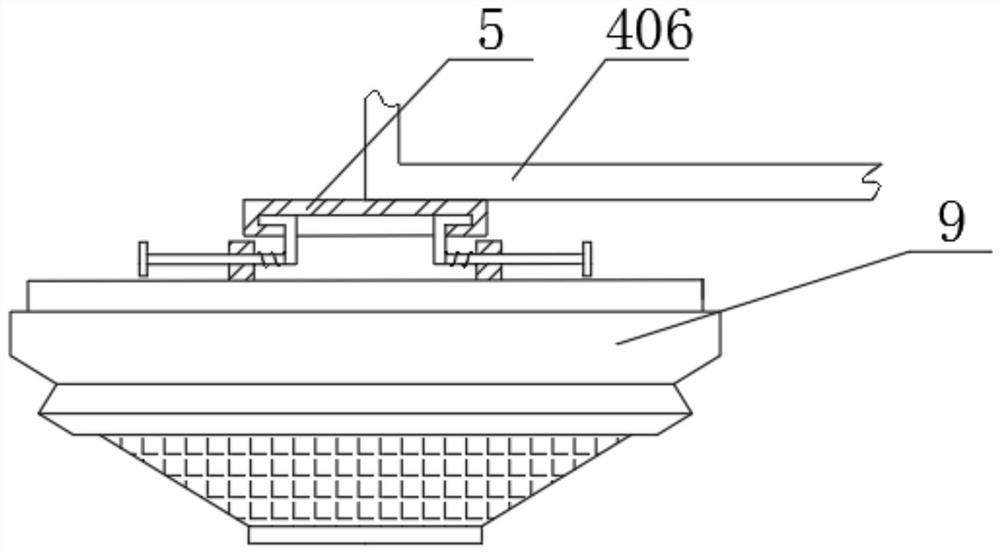

[0029] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

[0030] A fire alarm device for an automobile stamping and welding workshop and its use method, comprising a mounting plate 1, the bottom end of the mounting plate 1 is fixedly connected with a fixing ring 3, the inner side of the mounting plate 1 is provided with a mounting hole 2, and the inner side of the fixing ring 3 is fixedly connected Rotating device 4 is arranged, and the bottom end of rotating device 4 is fixedly connected with first connecting device 5, and the bottom end of rotating device 4 is fixedly connected with second connecting device 6, and the bottom end of first connecting device 5 and the second connecting device 6 both Fixedly connected with a fixed shell 8, the outside of the bottom of the fixed shell 8 is spirally connected with a connecting shell 9, the inner side of the connecting shell 9 is provided with a vent hole 10, t...

Embodiment 2

[0038] see figure 1 , figure 2 and Figure 6 , the present invention provides a technical solution:

[0039] A fire alarm device for an automobile stamping and welding workshop and its use method, comprising a mounting plate 1, the bottom end of the mounting plate 1 is fixedly connected with a fixing ring 3, the inner side of the mounting plate 1 is provided with a mounting hole 2, and the inner side of the fixing ring 3 is fixedly connected Rotating device 4 is arranged, and the bottom end of rotating device 4 is fixedly connected with first connecting device 5, and the bottom end of rotating device 4 is fixedly connected with second connecting device 6, and the bottom end of first connecting device 5 and the second connecting device 6 both Fixedly connected with a fixed shell 8, the outside of the bottom of the fixed shell 8 is spirally connected with a connecting shell 9, the inner side of the connecting shell 9 is provided with a vent hole 10, the inner side of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com