Brake actuator

A technology of actuators and brake cylinders, applied in the field of parking brake or emergency braking system, to reduce maintenance, improve flexibility and long-term, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

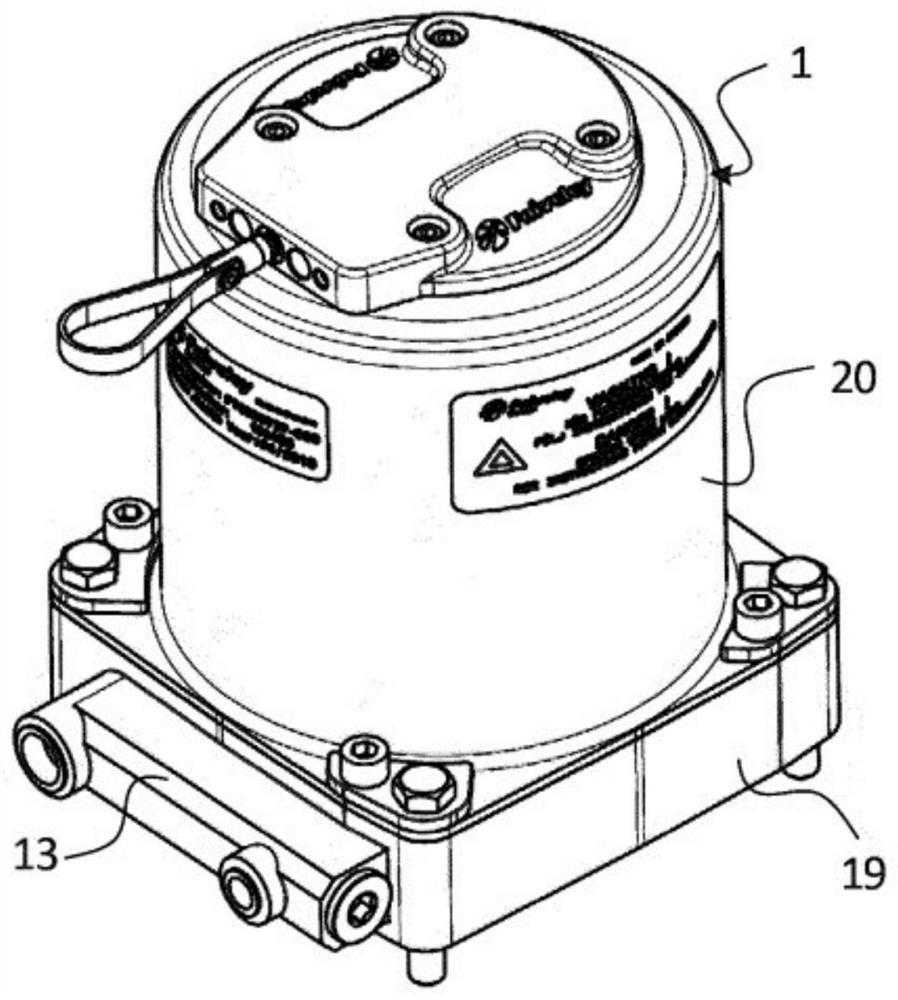

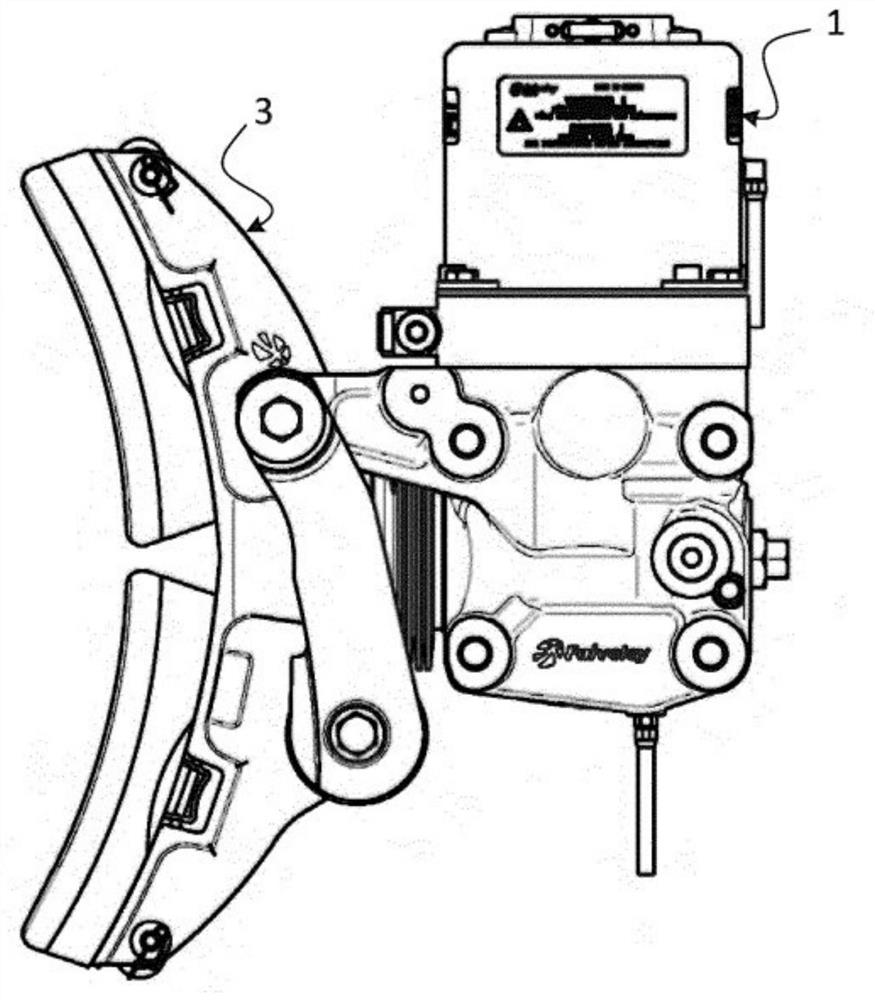

[0035] refer to figure 1 and 2 , describes a possible embodiment of a brake actuator 1 for activating the actuating capability of the brake 3 , which is adapted to act on the brake cylinder 2 . The utility model relates to a braking actuator of a railway vehicle braking system.

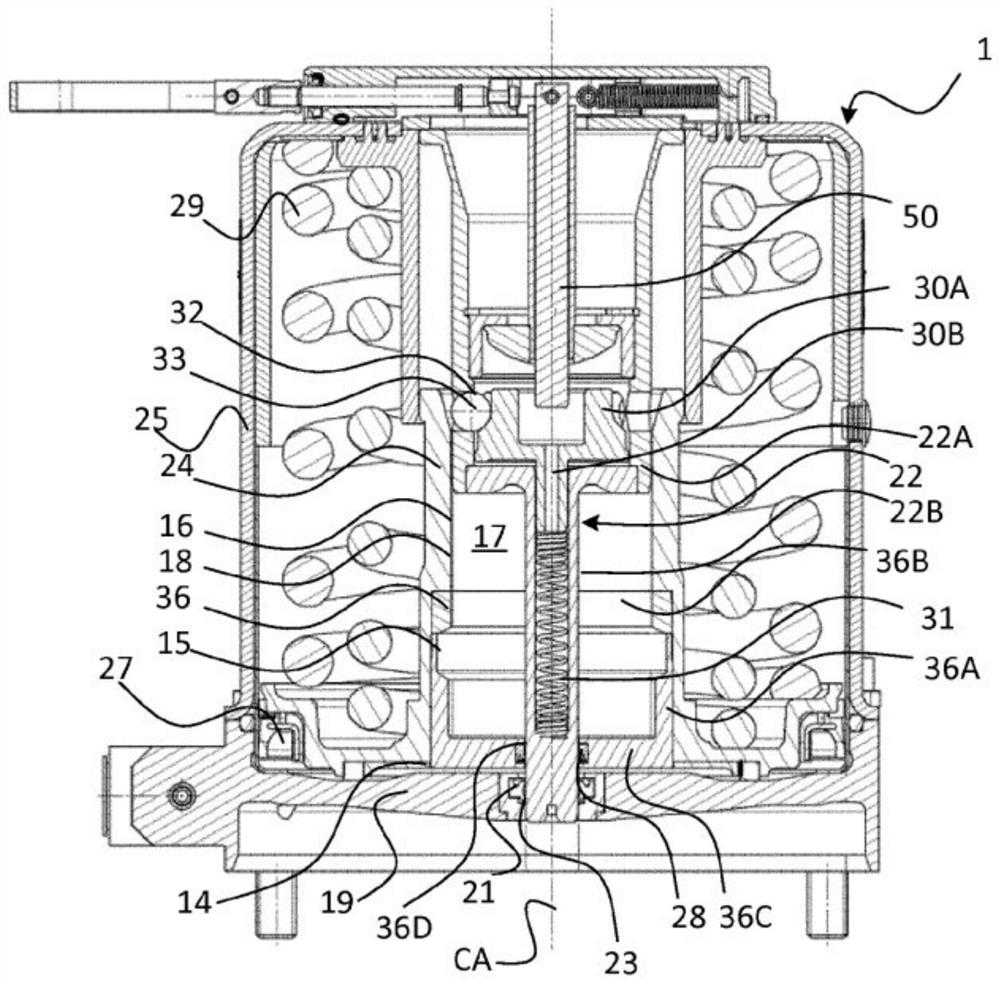

[0036] will now refer to image 3 Describing generally the brake actuator 1 and its features, the actuator 1 comprises a housing or body 20 having a base member 19 and a cylindrical portion 25 . The base member 19 has an opening 21 relative to the brake cylinder 2 . The opening 21 is a circular opening which slidingly receives a thrust member in the shape of a sleeve 22 which is fitted in the opening 21 in a sealing manner by means of sealing means 23 , for example an O-ring.

[0037] Furthermore, the brake actuator 1 comprises a piston 24 mounted in a cylindrical portion 25 of the main body 20 and together with the main body 20 defines a Figure 4 Pressure chamber 26 is shown. Pressurized fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com