Jaw plate with self-formed teeth

A technology of self-forming teeth and jaw plates, applied in the field of jaw plates, can solve the problems of high manganese steel high impact toughness, fast tooth wear, and increase the rheology of jaw plate teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

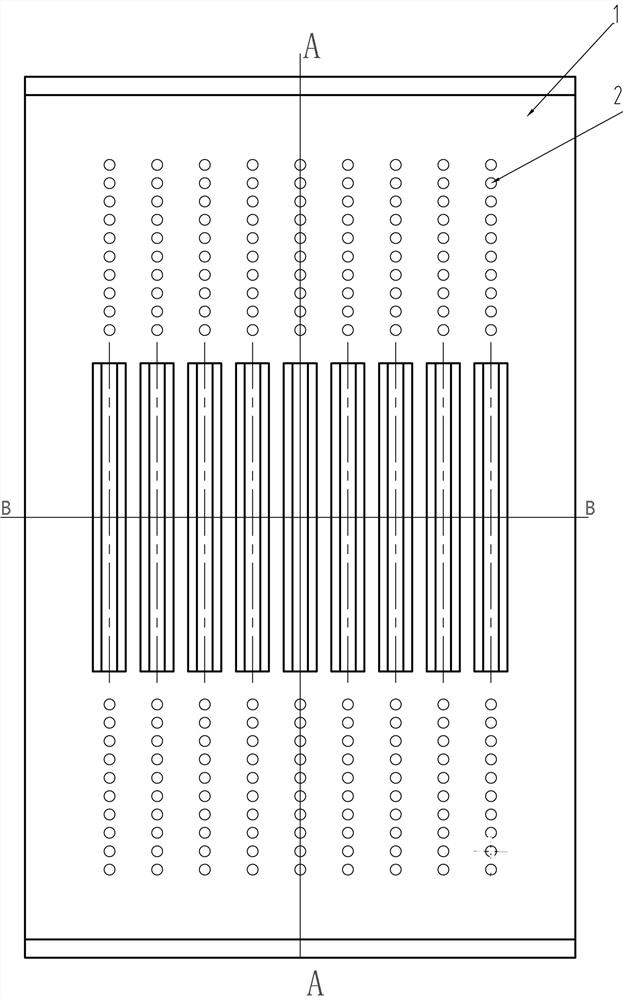

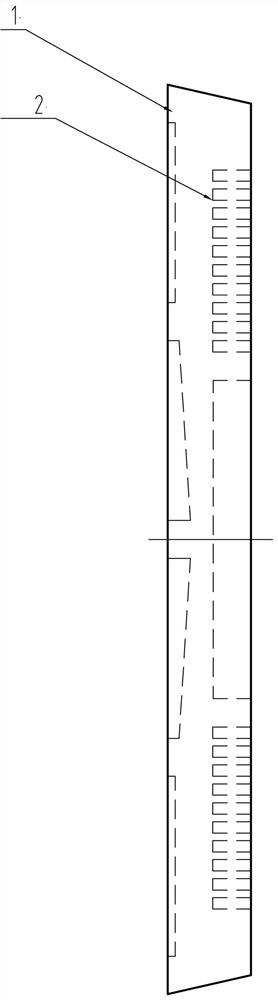

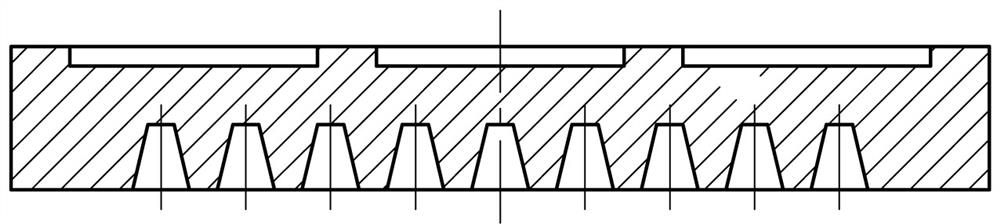

[0019] Such as Figure 1 to Figure 3 Shown is a new type of self-forming jaw plate, which is improved on the basis of the original jaw plate. Jaw plate is the abbreviation of tooth plate of jaw crusher. Jaw plate is divided into fixed jaw plate and movable jaw plate, that is, static jaw plate and movable jaw plate, which are the main components of jaw crusher. In the running state of the jaw crusher, the movable jaw is attached to the movable jaw plate to perform compound pendulum motion, forming an angle with the fixed jaw plate to squeeze the stone. Therefore, it is a relatively easy to damage accessory in the jaw crusher. The structure of the movable jaw is that molars are uniformly arranged on the jaw body, and the structure of the static jaw is also that molars are uniformly arranged on the jaw body, and the molars of the movable jaw and the molars of the static jaw are set in a meshing state.

[0020] At present, the jaw plates of jaw crushers are all made of high mang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com