Environment-friendly and energy-saving screening and sand washing all-in-one machine

An energy-saving, all-in-one technology, used in solid separation, filtration separation, wet separation, etc., can solve the problems of waste of water resources in sand washing machines, single function of sand washing machines, uneven mixing of sand and water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

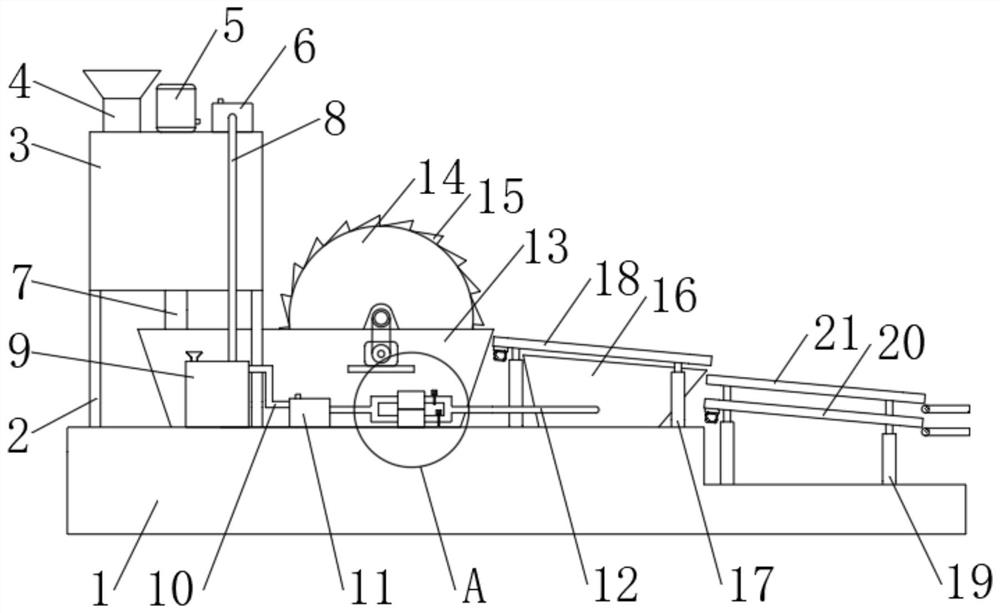

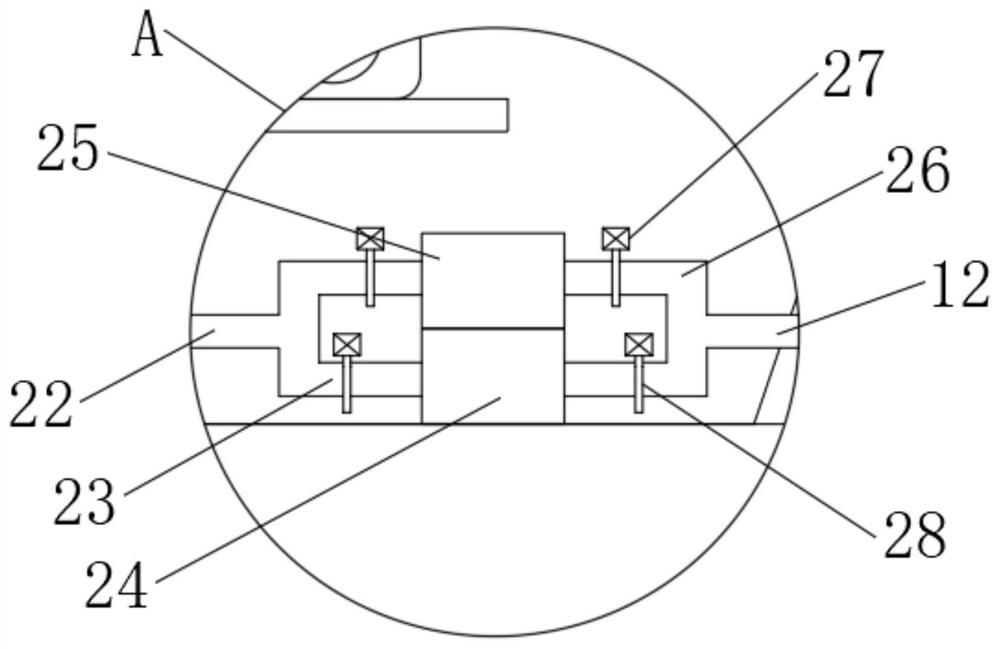

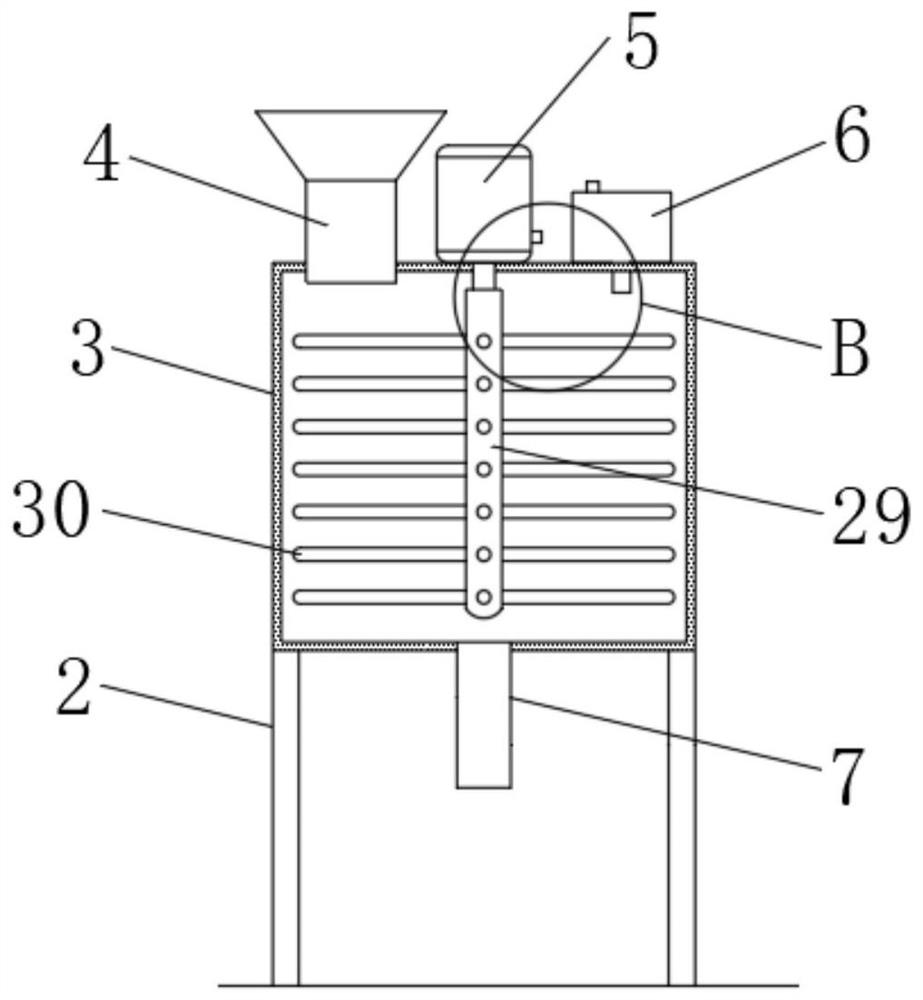

[0032] like Figure 1-8 As shown, the embodiment of the present invention provides an environmentally friendly and energy-saving screening sand washing machine, including a base 1, four first brackets 2 are fixedly connected to the front end of the top of the base 1, and the top ends of the four first brackets 2 are fixedly connected to the bottom of the mixing drum 3 The center position of the top of the mixing drum 3 is fixedly connected with a first motor 5, the first motor 5 is provided with a first transmission shaft 31 and the first transmission shaft 31 extends inward through the top of the mixing drum 3 and is fixedly connected to the top of the rotating shaft 29, the rotating shaft The outer diameter of 29 is fixedly connected with stirring blades 30 evenly distributed from top to bottom, starting the first motor 5 can make the first transmission shaft 31 rotate and drive the rotating shaft 29 to rotate together, and then drive the stirring blades 30 to also rotate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com