Filter debugging method and device, electronic equipment and readable memory medium

A debugging method and filter technology, applied in the field of reinforcement learning, can solve the problems of high labor cost and time cost, low filter debugging efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

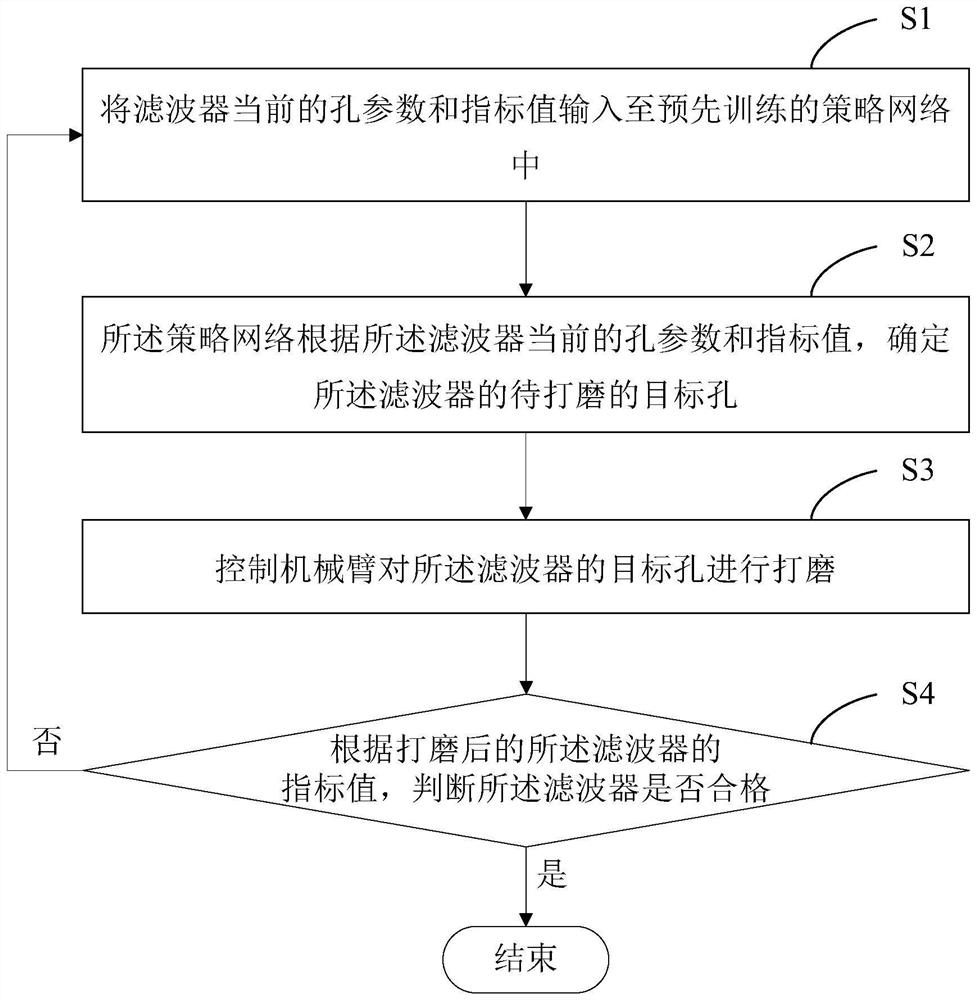

[0030] Such as figure 1 As shown, the present application provides a filter debugging method, including the following steps:

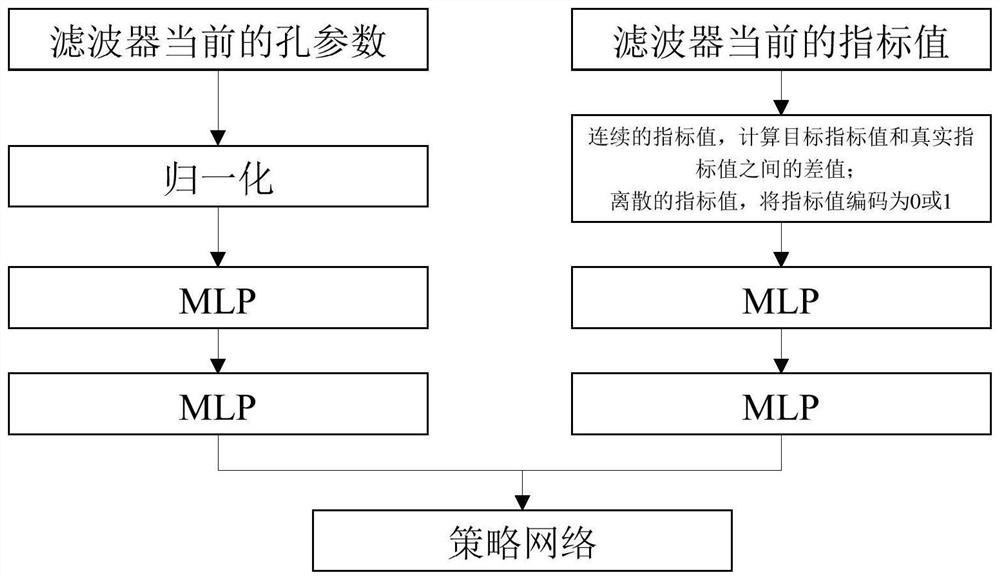

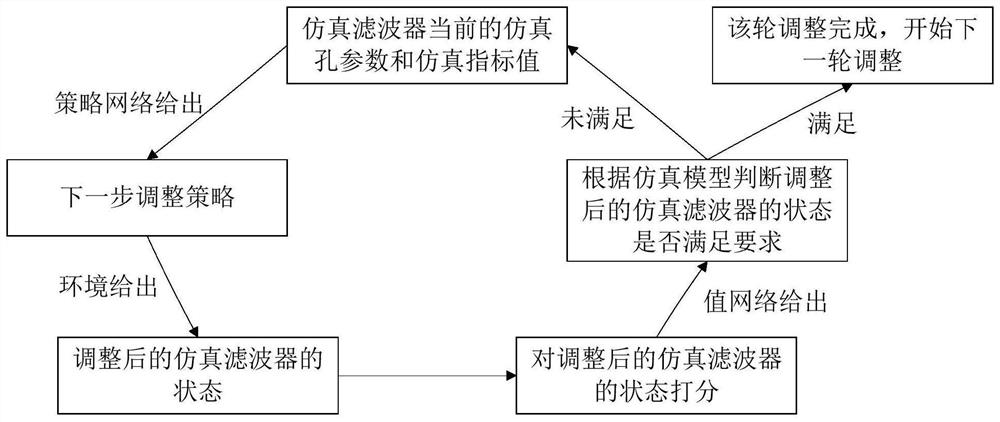

[0031] Step S1: Input the current hole parameters and index values of the filter into the pre-trained policy network;

[0032] Step S2: The policy network determines the target hole to be polished of the filter according to the current hole parameters and index values of the filter;

[0033] Step S3: controlling the mechanical arm to polish the target hole of the filter;

[0034] Step S4: According to the index value of the polished filter, judge whether the filter is qualified, if the filter is qualified, then end; if the filter is not qualified, execute the steps S1 to all Repeat step S4 until the filter is qualified.

[0035] In this application, the filter may include a ceramic dielectric filter or other filters. The aperture parameters of the filter may include aperture depth and aperture, and the filter index may include at least one of c...

no. 2 example

[0076] Such as Figure 5 As shown, the present application provides a filter debugging device 300, including an input module 301, a control module 302, a judgment module 303 and a pre-trained policy network 304;

[0077] The input module 301 is used to input the current hole parameters and index values of the filter into the strategy network 304;

[0078] The strategy network 304 is used to determine the target hole to be polished of the filter according to the current hole parameters and index values of the filter;

[0079] The control module 302 is used to control the mechanical arm to grind the target hole of the filter;

[0080] The judging module 303 is used to judge whether the filter is qualified according to the index value of the filter after polishing, if the filter is qualified, then end; if the filter is unqualified, trigger the input module 301, strategy Network 304 and control module 302 process until the filter is qualified.

[0081] Optionally, the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com