Intelligent vehicle debugging method, server and debugging instrument of tire pressure monitoring system

A tire pressure monitoring and server technology, applied in the automotive field, can solve the problems of not being able to effectively meet the production requirements of the vehicle production line, high requirements for production line debugging personnel, long operating time, etc., to achieve intelligent debugging, simplify the debugging process, and reduce operations the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

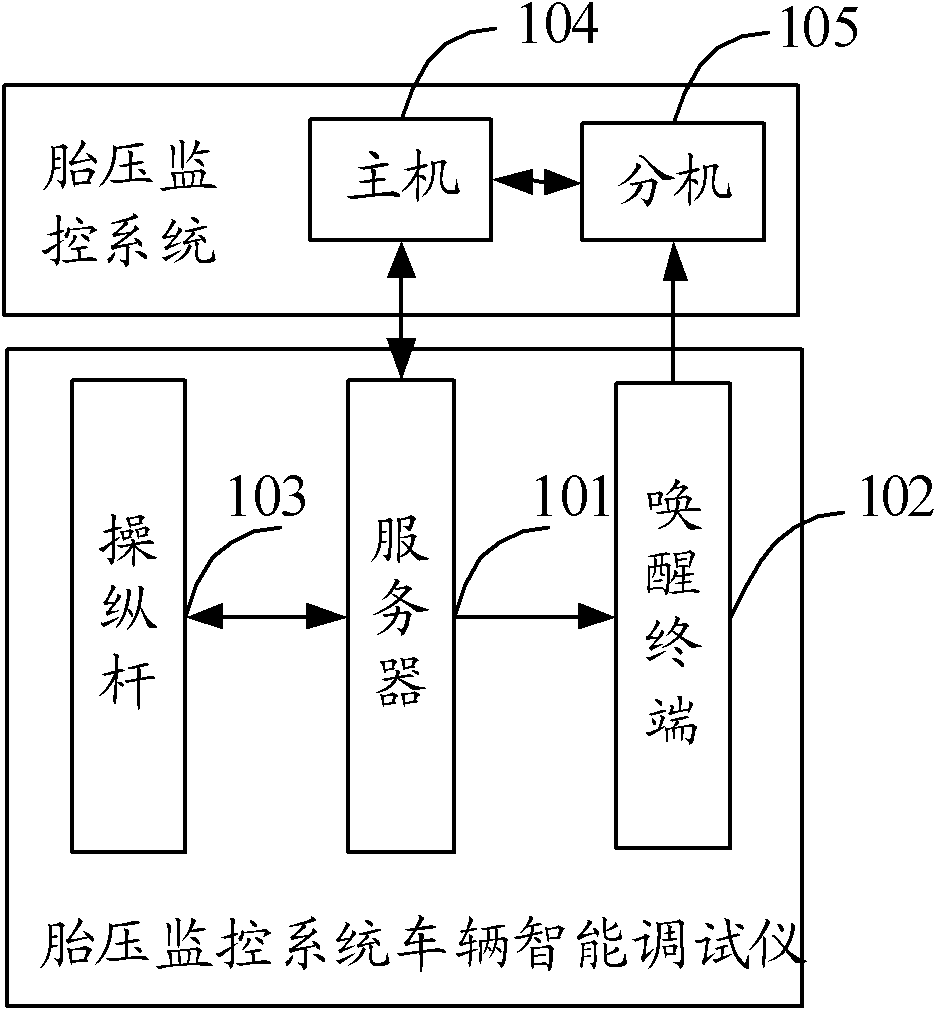

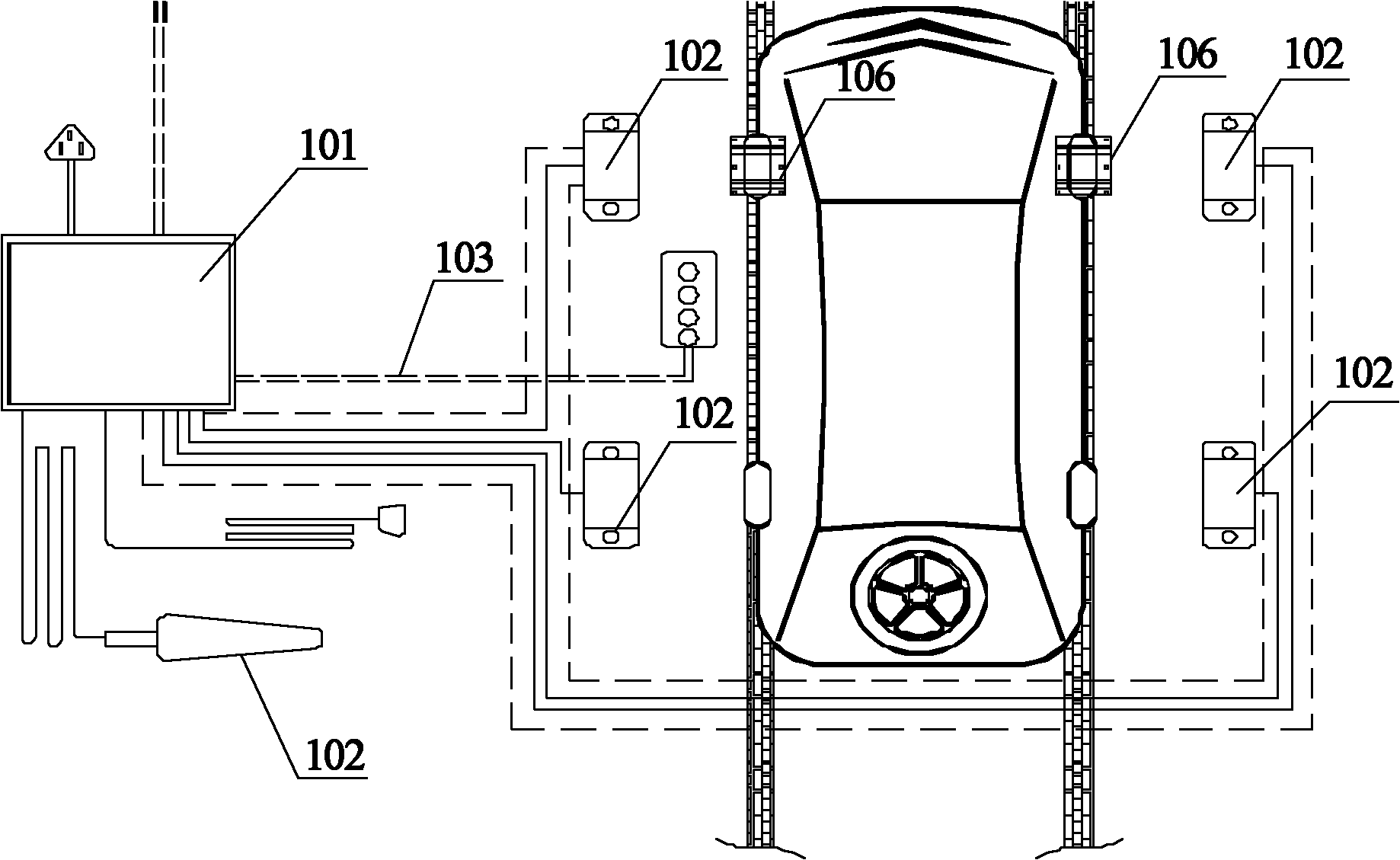

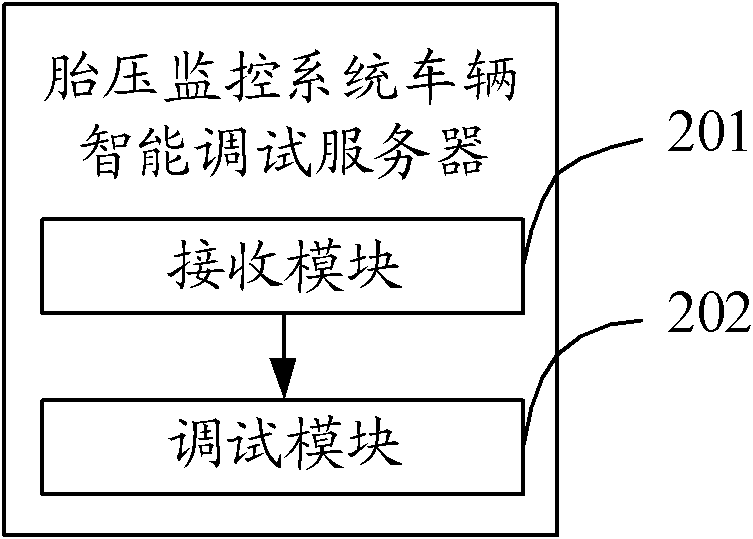

[0070] The solution of the embodiment of the present invention is mainly to debug the brake valve, the matching of the host and the extension and the factory initialization settings in the tire pressure monitoring system through a debugger including a server, a wake-up terminal and a joystick, so as to realize the product in the whole The intelligent debugging of the car production line improves production efficiency.

[0071] The tire pressure monitoring system in the present invention may be BMBS or TPMS. The technical solution of the present invention will be described in detail below taking the tire pressure monitoring system as BMBS as an example. The technical solution of the present invention is also applicable to the situation where the tire pressure monitoring system is TPMS.

[0072] The core of the TPMS (Tire Pressure Monitoring System) technology is to monitor the tire pressure and temperature in real time, and provide information to the driver. BMBS has all the functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com