Robot hand-eye calibration method and device and robot

A calibration method and hand-eye calibration technology, applied in the field of robot calibration, can solve problems such as large manual calibration error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

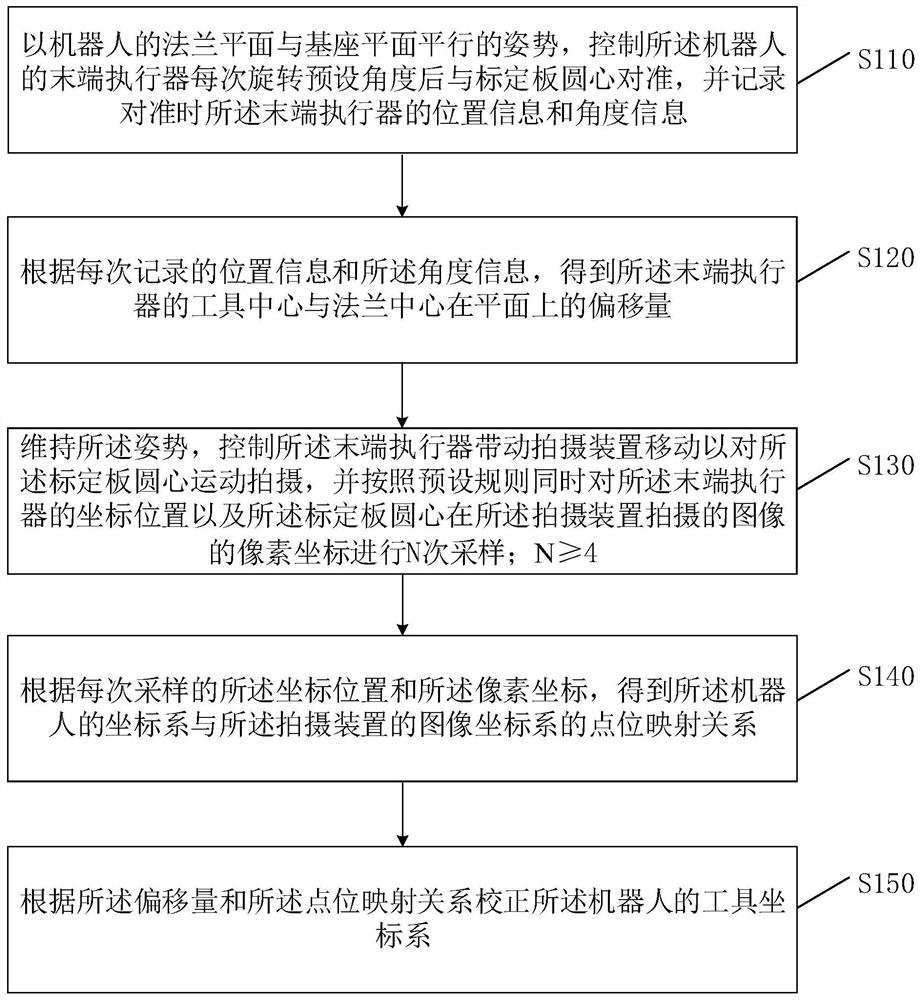

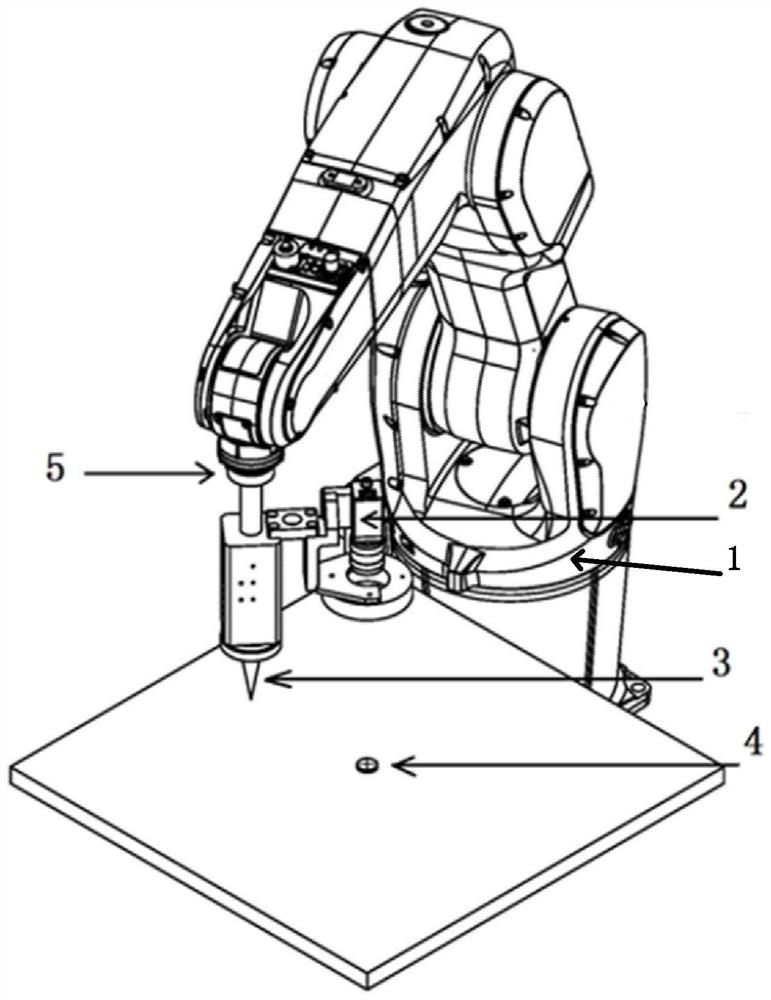

[0046] Such as figure 1 As shown, it is a schematic flow chart of the robot hand-eye calibration method provided by Embodiment 1 of the present invention. This embodiment is applicable to the application scenario of hand-eye calibration for industrial robots and shooting devices. The method can be performed by a robot hand-eye calibration device, which can be a processor, an intelligent terminal, a tablet or a PC, etc.; in this embodiment of the application Taking the robot hand-eye calibration device as the execution subject for illustration, the method specifically includes the following steps:

[0047] S110. With the attitude that the flange plane of the robot is parallel to the base plane, control the end effector of the robot to align with the center of the calibration plate after each rotation of the preset angle, and record the position information of the end effector during alignment and angle information; wherein, the center of the calibration plate is the position o...

Embodiment 2

[0084] Such as Figure 5 Shown is a schematic flow chart of the robot hand-eye calibration method provided by Embodiment 2 of the present invention. On the basis of the first embodiment, this embodiment also provides a process of correcting the tool coordinate system of the robot according to the offset and point-position mapping relationship to grab the workpiece, so as to realize the precise grasping of the workpiece by the robot. The method specifically includes:

[0085] S210. Using the posture of the flange plane of the robot parallel to the base plane, photograph the current workpiece through the photographing device, and obtain the pixel coordinates and the workpiece angle of the image of the current workpiece on the photographing device;

[0086] Since the robot's flange plane is parallel to the base plane, the robot's flange plane is parallel to the robot base plane. At this time, R(X)=180°, R(Y)=0°, and the Z axis is perpendicular to the XY plane, that is, perpendi...

Embodiment 3

[0099] Such as Figure 6 Shown is the robot hand-eye calibration device provided by Embodiment 3 of the present invention. On the basis of Embodiment 1 or 2, the embodiment of the present invention also provides a robot hand-eye calibration device 6, which includes:

[0100] The tool coordinate system calibration module 601 is used to control the end effector of the robot to align with the center of the calibration plate after each rotation of the preset angle with the attitude that the flange plane of the robot is parallel to the base plane, and record the alignment. position information and angle information of the end effector;

[0101] In an implementation example, with the posture that the flange plane of the robot is parallel to the plane of the base, the end effector of the robot is controlled to align with the center of the calibration plate after each rotation of a preset angle, and the end effector of the robot is recorded during the alignment. When the position in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com