Automatic muck truck cleaning equipment capable of recycling water sources for constructional engineering

A construction engineering and automatic cleaning technology, which is applied to vehicle cleaning equipment, vehicle cleaning, vehicle exterior cleaning devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

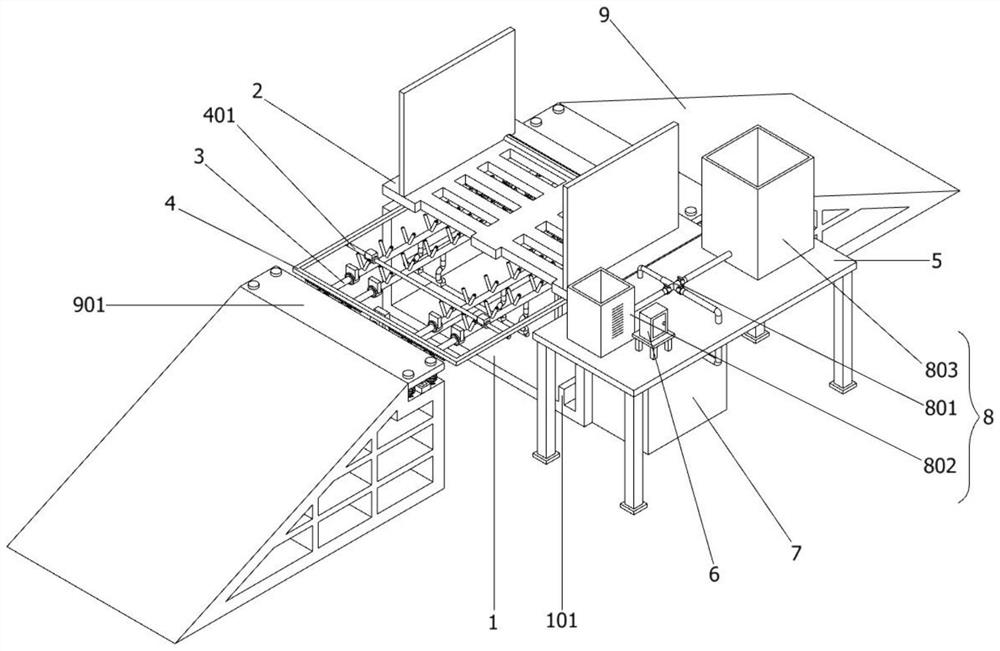

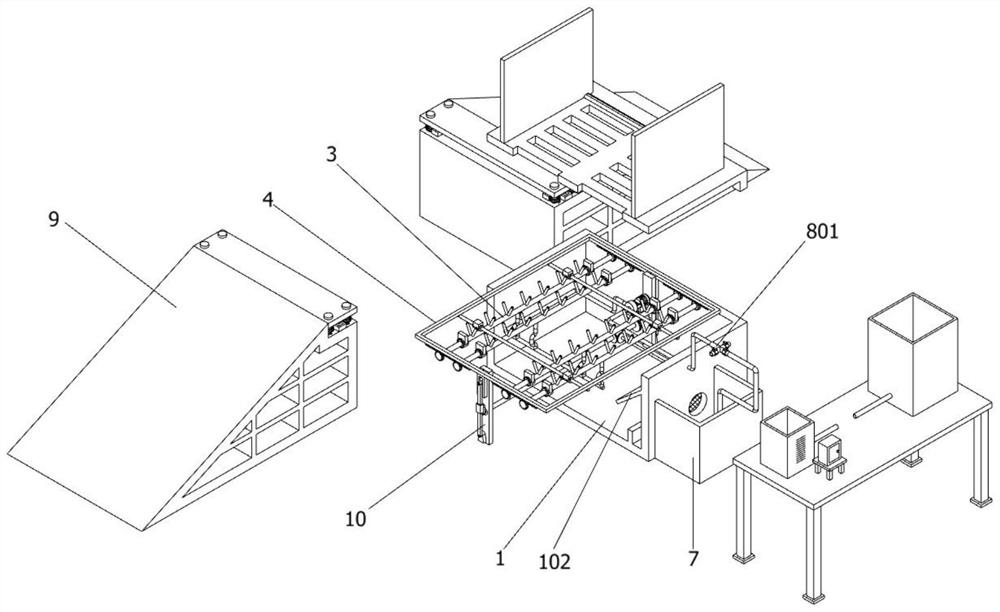

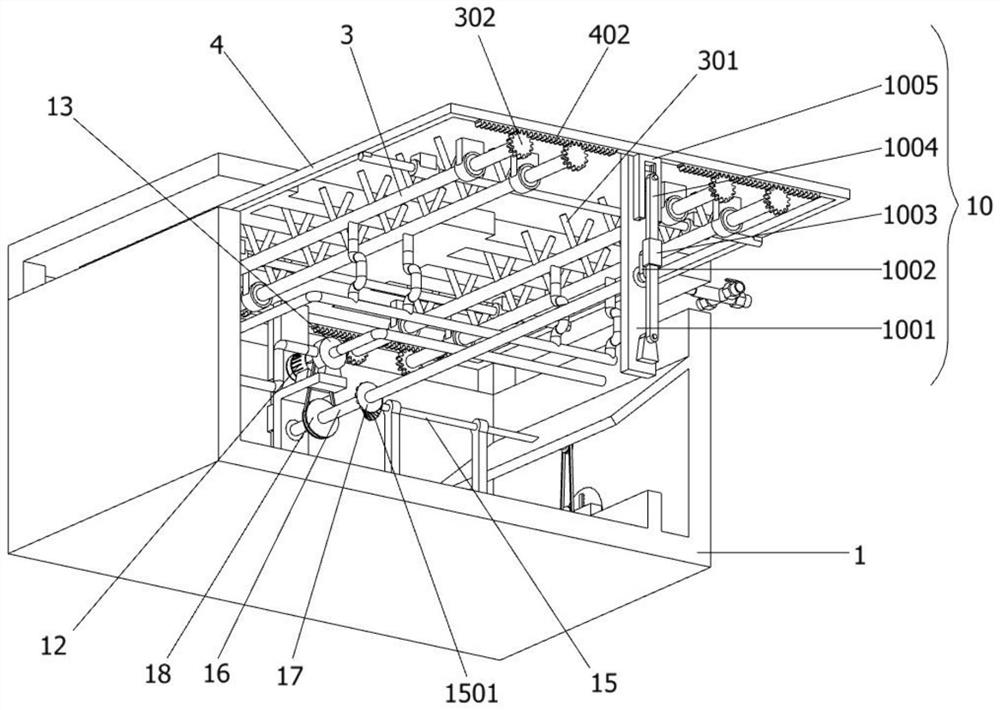

[0035] as attached figure 1 To attach Figure 10 Shown:

[0036] The invention provides an automatic cleaning device for muck trucks with reusable water sources for construction projects, which includes: a sump body 1, a cleaning frame 2 is installed on the upper part of the sump body 1, and the sump body 1 includes a partition 101 and a flow guide Plate 102, the front side of the bottom end of the sump body 1 is provided with a partition 101, and the height of the partition 101 accounts for 1 / 6 of the depth of the sump body 1, and the front side of the sump body 1 is provided with a deflector 102, and The deflector 102 is distributed in an oblique shape, and the right side of the sump body 1 is fixedly inlaid with a circular filter; the upper end surface of the cleaning frame 2 is symmetrically arranged with two baffles; the bottom surface of the cleaning frame 2 is rotated through the shaft sleeve Four water spraying mechanisms 3 are connected, and the water spraying mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com