A device for double weight transmission and alternate loading

A weight and transmission arm technology, applied in the field of measurement, can solve the problems of high manufacturing cost, large time consumption, long working time, etc., and achieve the effect of satisfying discontinuous weighing, shortening the moving stroke, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

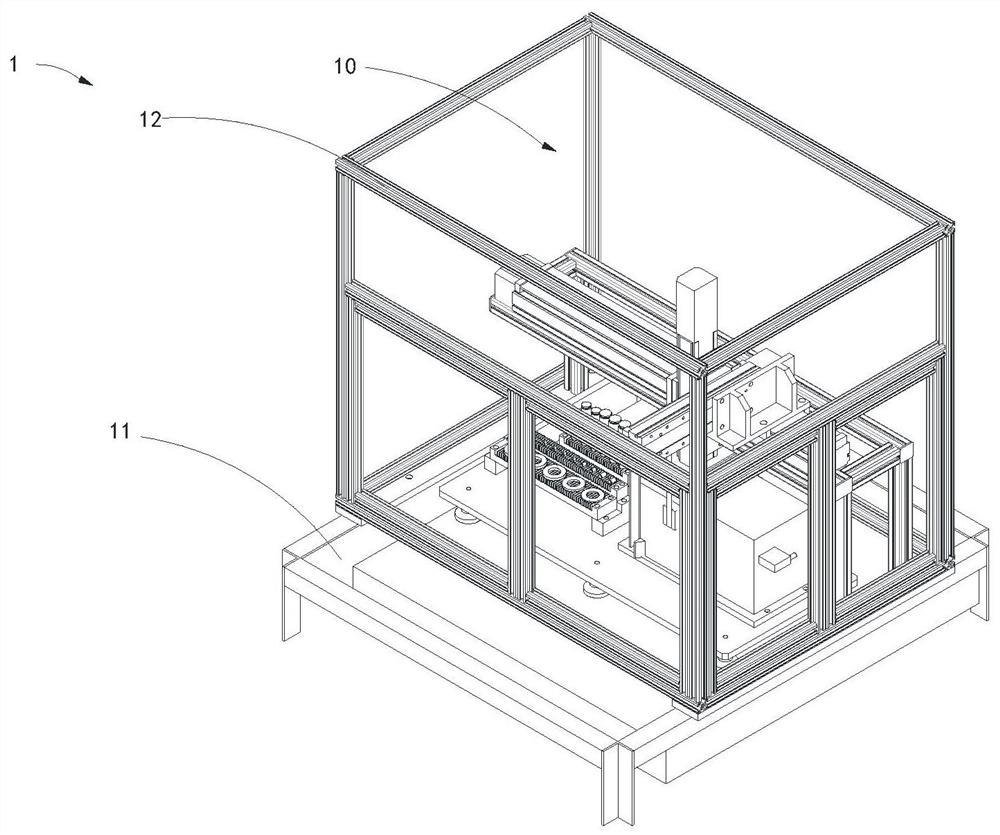

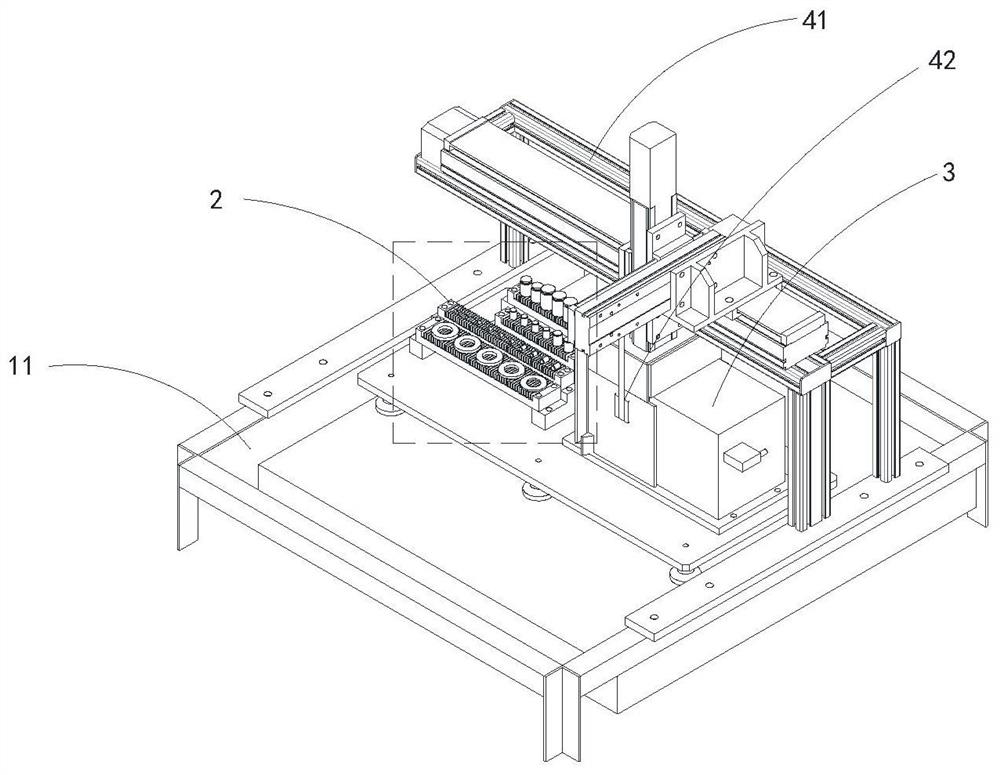

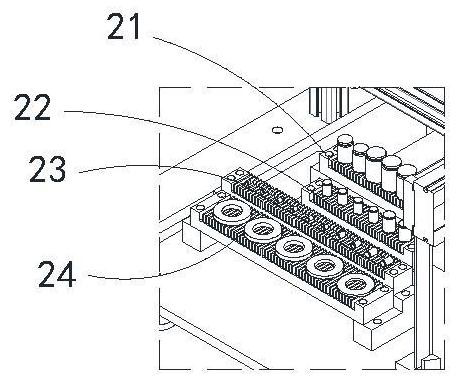

[0047] Reference manual attached Figure 1 to Figure 8 , The present invention provides a double weight transmission and alternate loading device, the double weight transmission and alternate loading device is used for loading, transmission, unloading and detection of weights. The double weight transmission and alternate loading device has high weight detection efficiency, realizes simultaneous transmission of two weights and alternate loading and unloading, and can reduce the time spent on weight detection. The dual-weight transmission and alternate loading device is especially suitable for the detection of gram weights.

[0048] Specifically, the device for double weight transmission and alternate loading includes a device main body 1, a workbench 2, a mass comparator 3 and a weight transmission mechanism 4, and the device main body 1 includes a base 11 and a cover 12, the The cover 12 is installed on the base 11, and the cover 12 and the base 11 surround and form a loading...

Embodiment 2

[0072] Reference manual attached Figure 9 to Figure 13 , the second preferred embodiment of the double-weight transmission and alternate loading device provided by the present invention is described. In the second preferred embodiment of the double-weight transmission and alternate loading device, the same as the first preferred implementation above The difference between the two examples is that, in the second preferred embodiment, the weight placement part 421 of the transfer arm 42 has a first groove 423, which is used to carry the weight to be measured lying on the side, so as to Improves stability during transport of the weight to be measured.

[0073] Reference manual attached Figure 9 , in this preferred embodiment, the weight to be measured can be placed in the first groove 423 of the transfer arm 42, so that the weight transport can be improved during the transportation of the weight to be measured stability, and improve the transport efficiency of the weight to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com