Board feeding mechanism for immersion gold, immersion copper and black oxide fully-automatic board insertion machine

A black oxidation, fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of low efficiency of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

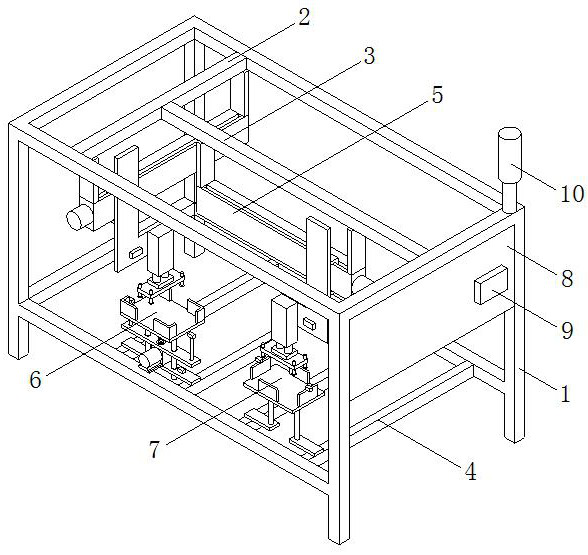

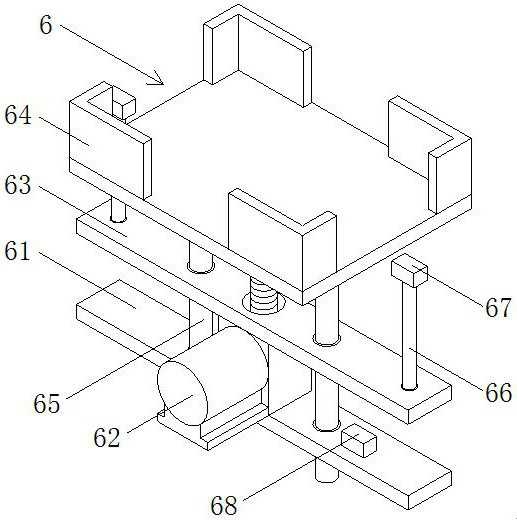

[0026] Example: such as Figure 1-5 As shown, the present invention is an upper plate mechanism for an immersion gold, immersion copper, and black oxidation fully automatic board insertion machine, including a support assembly, and the support assembly consists of a support frame 1, a first support rod 2, and a second support rod 3 and several third support rods 4, the bottom of the first support rod 2 and the second support rod 3 are fixedly installed with the upper plate assembly 5, and the tops of several third support rods 4 are fixedly installed with circuit board storage The assembly 6 and the release paper storage assembly 7 located on one side of the circuit board storage assembly 6, the circuit board storage assembly 6 and the release paper storage assembly 7 are respectively located below the two upper board assemblies 5;

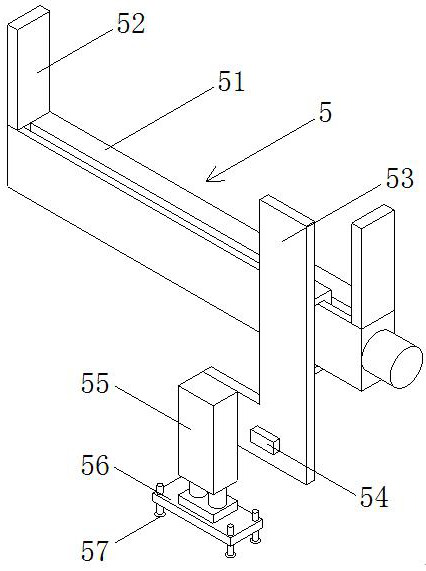

[0027] Upper plate assembly 5 is made up of electric guide rail 51, mounting plate 52, connecting plate 53, vacuum generator 54, cylinder 55, hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com