Anti-divergence waterway structure and washing machine water intake device

A waterway structure and water flow technology, applied in the field of washing machines, can solve the problems of water flow vortex at the bend of the flow channel, water divergence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

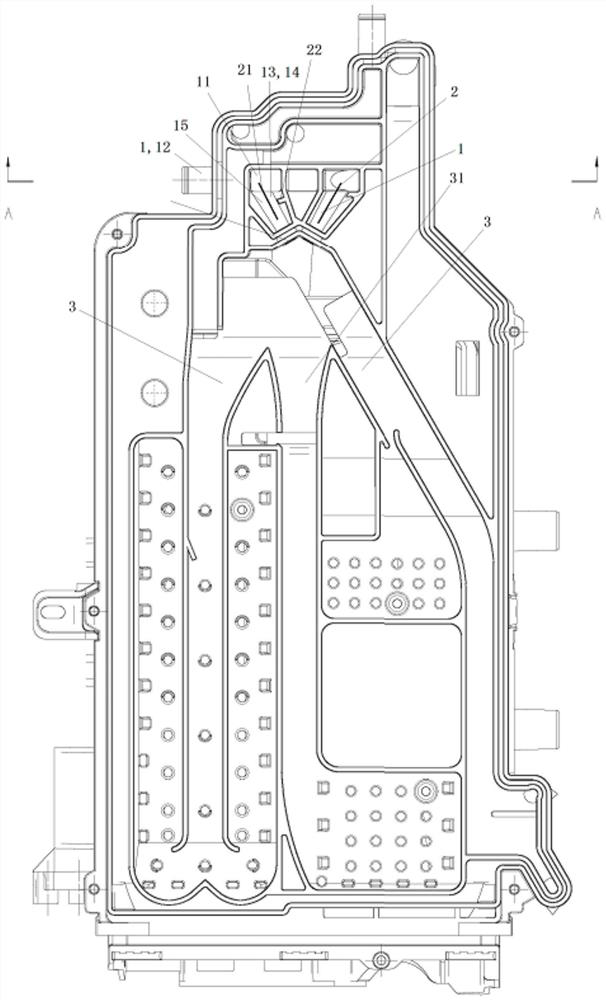

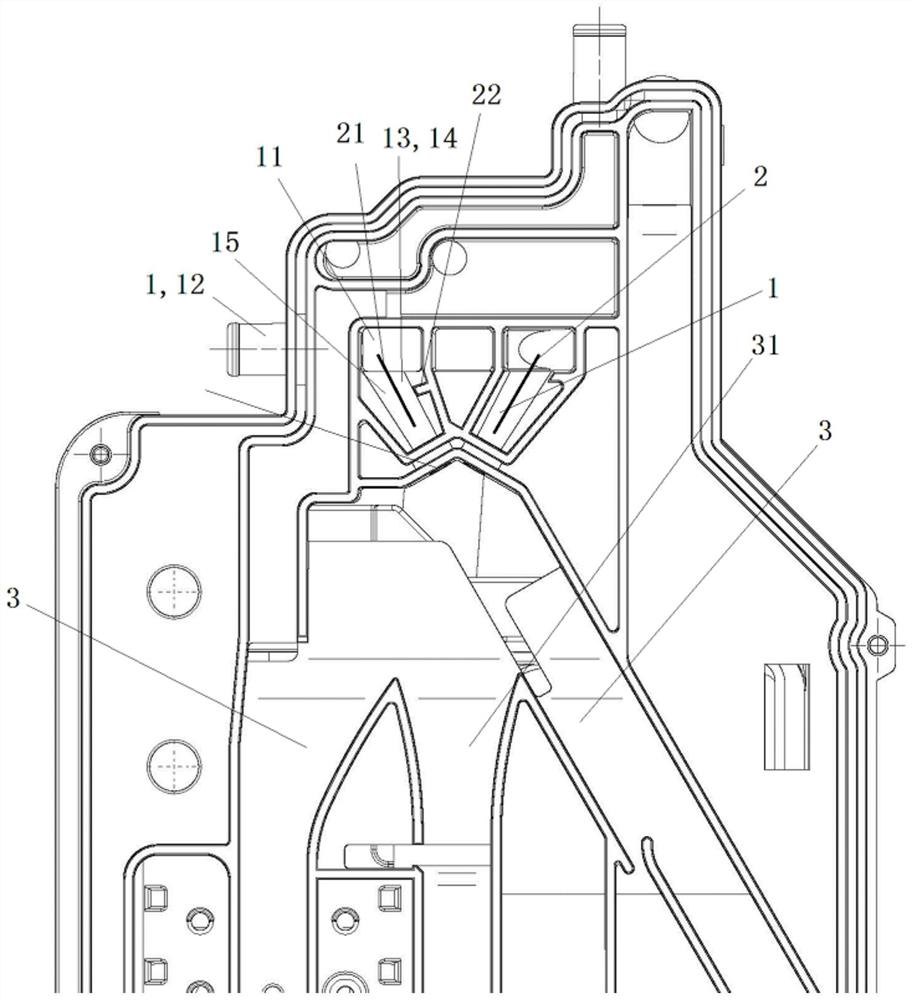

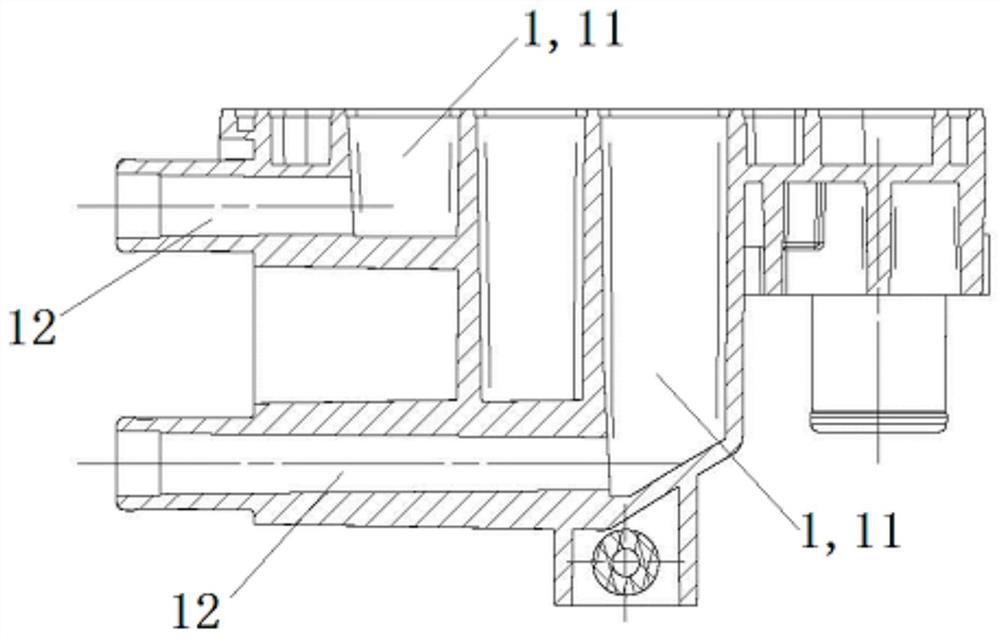

[0034] Such as Figure 1 to Figure 3 As shown, this embodiment introduces an anti-divergence waterway structure, including: a flow channel 1 providing a flow space for the water flow; the flow channel 1 is provided with at least one bend 11 to change the flow direction of the water flow, between the bend 11 and A diversion rib 2 is provided between the water outlets 10 of the flow channel 1 to guide the vortex of the water flow at the bend 11 to spray in the axial direction of the water outlet 10 under the action of the diversion rib 2 .

[0035] Through the above arrangement, the flow direction of the bent flow channel can be corrected under the action of the diversion rib, so as to guide the vortex of the water flow at the bend of the flow channel and avoid the divergence of the water outlet from the flow channel.

[0036] In this embodiment, the first flow guide rib 21 is arranged in the bending downstream flow channel 13, and the first flow guide rib 21 divides the inside ...

Embodiment 2

[0042] Such as Figure 1 to Figure 3 As shown, this embodiment also has the following additional technical features based on the first embodiment above. In order to increase the flow rate of the water and reduce the divergence of the water flow, a radial protrusion is provided in the first branch flow channel 14 to change the width of the flow channel. The second diversion rib 22. By setting the second diversion ribs, the significant technical progress of reducing the radial width of the outlet water branch flow channel downstream of the bend, increasing the water outlet flow rate, and reducing the divergence of the outlet water is achieved.

[0043] In this embodiment, the second guide rib 22 is located on the side wall of the bent downstream flow channel 13 and protrudes radially toward the center of the flow channel 1 to reduce the width of the first branched flow channel 14 downstream of the bend.

[0044] In this embodiment, the second flow guide rib 22 is located on the...

Embodiment 3

[0048] Such as Figure 1 to Figure 3 As shown, this embodiment introduces a water inlet device for a washing machine, which includes at least one water inlet channel. The water channel structure described in the above embodiment is provided on the water inlet channel. The water outlet 10 sprays into the corresponding flushing channel 3 .

[0049] In this embodiment, the water inlet device of the washing machine includes two flow channels 1 arranged at a certain angle interlaced with each other, and the axes of the water outlets 10 of the two flow channels 1 intersect at a certain angle with each other. The downstream of the two flow channels 1 are respectively provided with a relatively coaxial flushing flow channel 3, and the inlets of the flushing flow channels 3 are respectively arranged towards the water outlets 10 of the corresponding flow channels 1, so that the water jets ejected from the water outlets 10 of each flow channel Spray into the corresponding flushing chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com