Cutting device of female knit sport vest with sweat absorption function

A functional, ladies' technology, applied in the field of sports vest production, which can solve problems such as affecting comfort, low work efficiency, discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

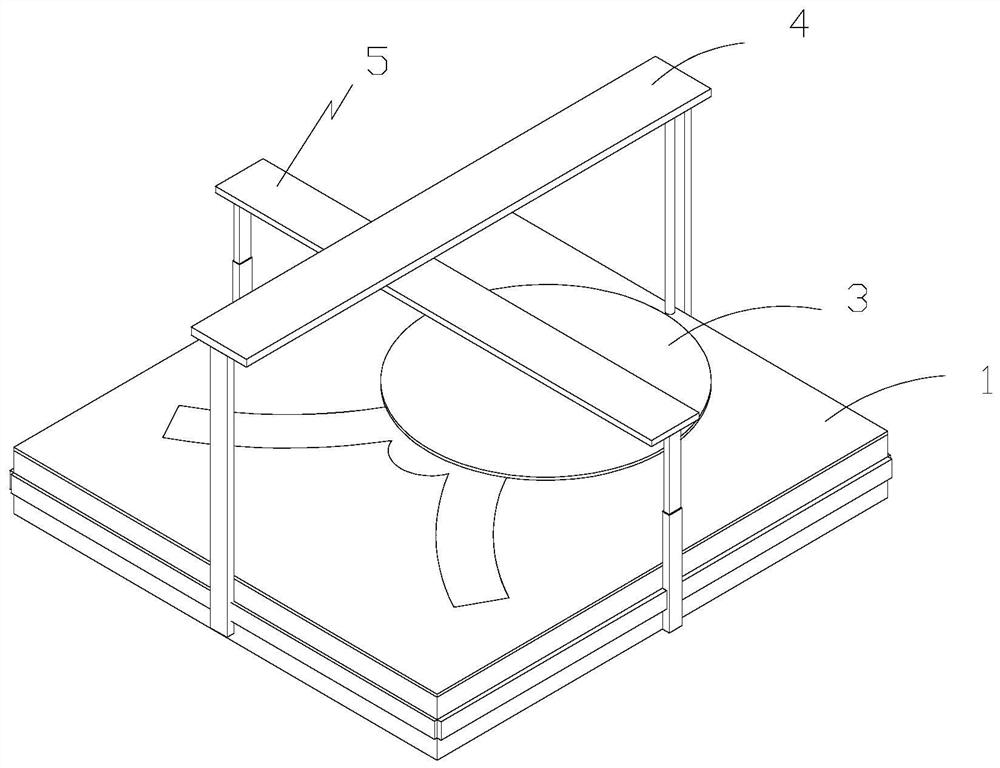

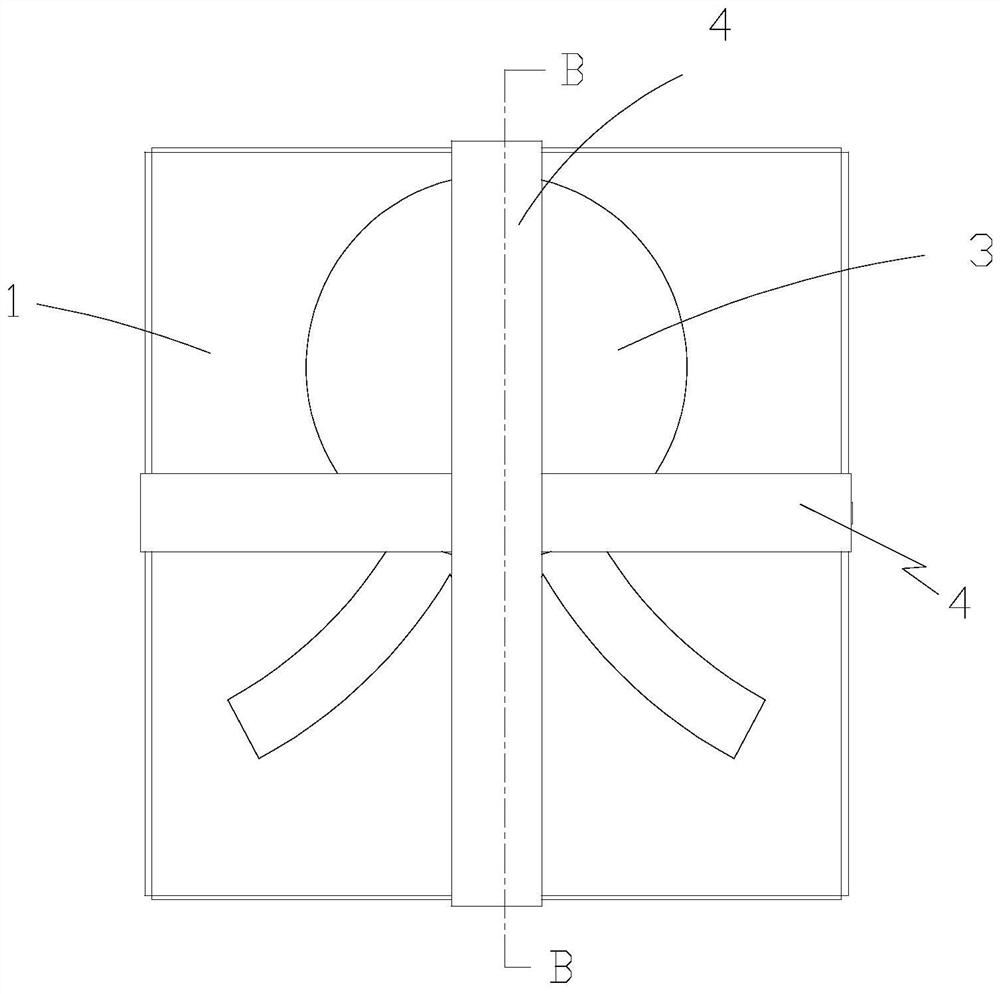

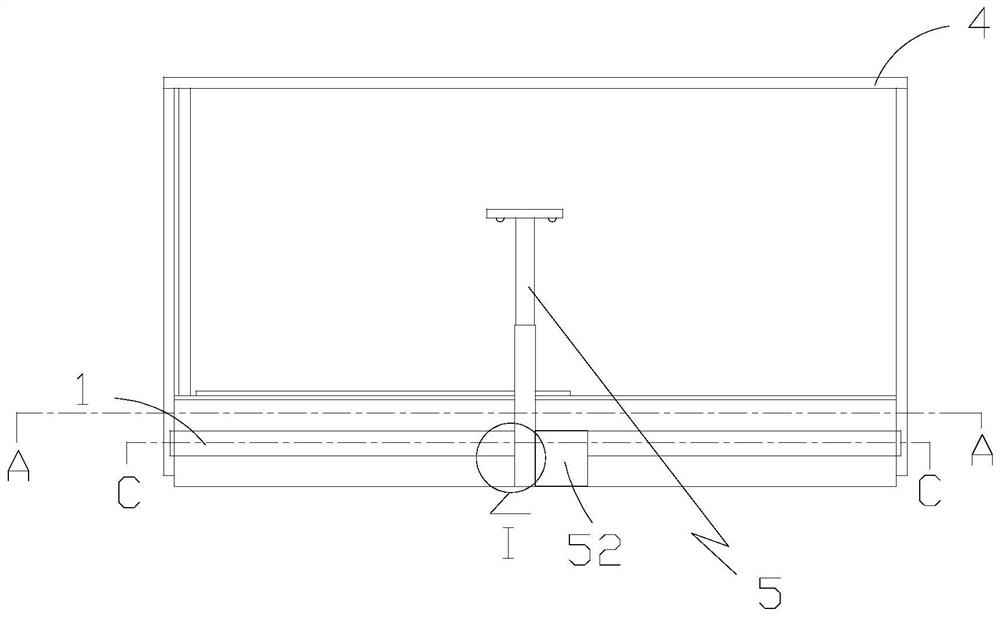

[0037] Such as Figure 1-16 Shown, a kind of cutting equipment of women's knitted sports vest with sweat-absorbing function, comprises main body 1, forming device 2, workbench 3, cutting device 4, stabilizing device 5; Described forming device 2 comprises track 21, chute 22, Moving mechanism 6, steering mechanism 7, pneumatic mechanism 8; the molding device 2 is set inside the main body 1; the workbench 3 is movably embedded in the upper end of the main body 1; the cutting device 4 is set in the main body 1 It can move along the length direction of the main body 1; the stabilizing device 5 is arranged on both sides of the main body 1; the cross section of the track 21 is herringbone, and is fixed at the bottom of the main body 1; the radian of the track 21 is in line with the cuff of the product The radians are consistent; the chute 22 is set on the inside of the track 21; the pneumatic mechanism 8 is set inside the track 21 for driving the start of the steering mechanism 7; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com