Automatic wall surface roughening device and wall surface construction method thereof

A brushing device and automatic technology, which are applied in construction, building structure, processing of building materials, etc., can solve the problems of difficult to control the depth of brushing, unfavorable adhesion between tiles and walls, and easy falling off of tiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following is attached Figure 1-6 The application is described in further detail.

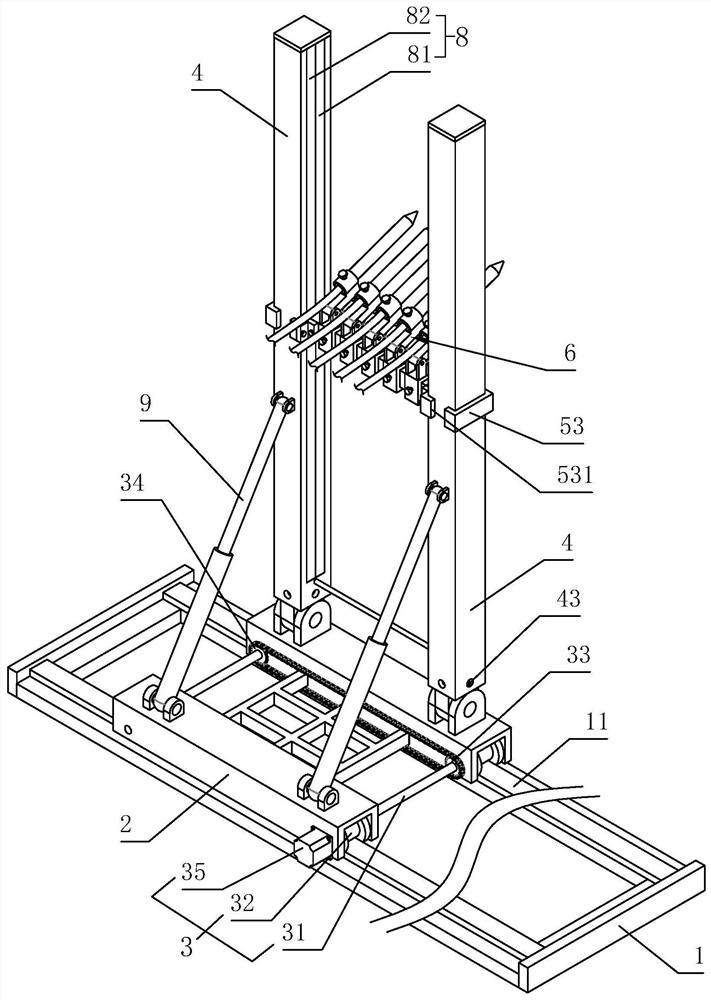

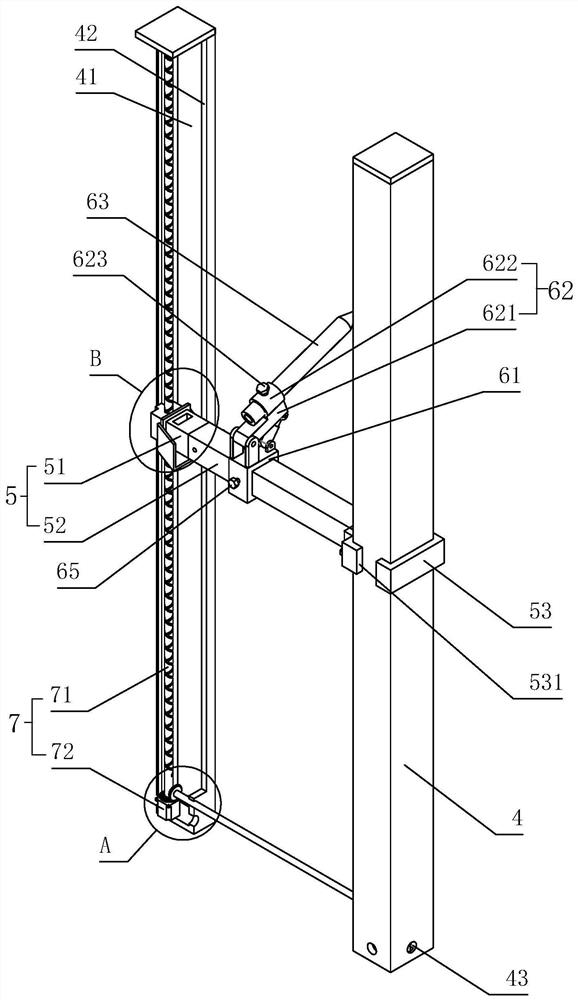

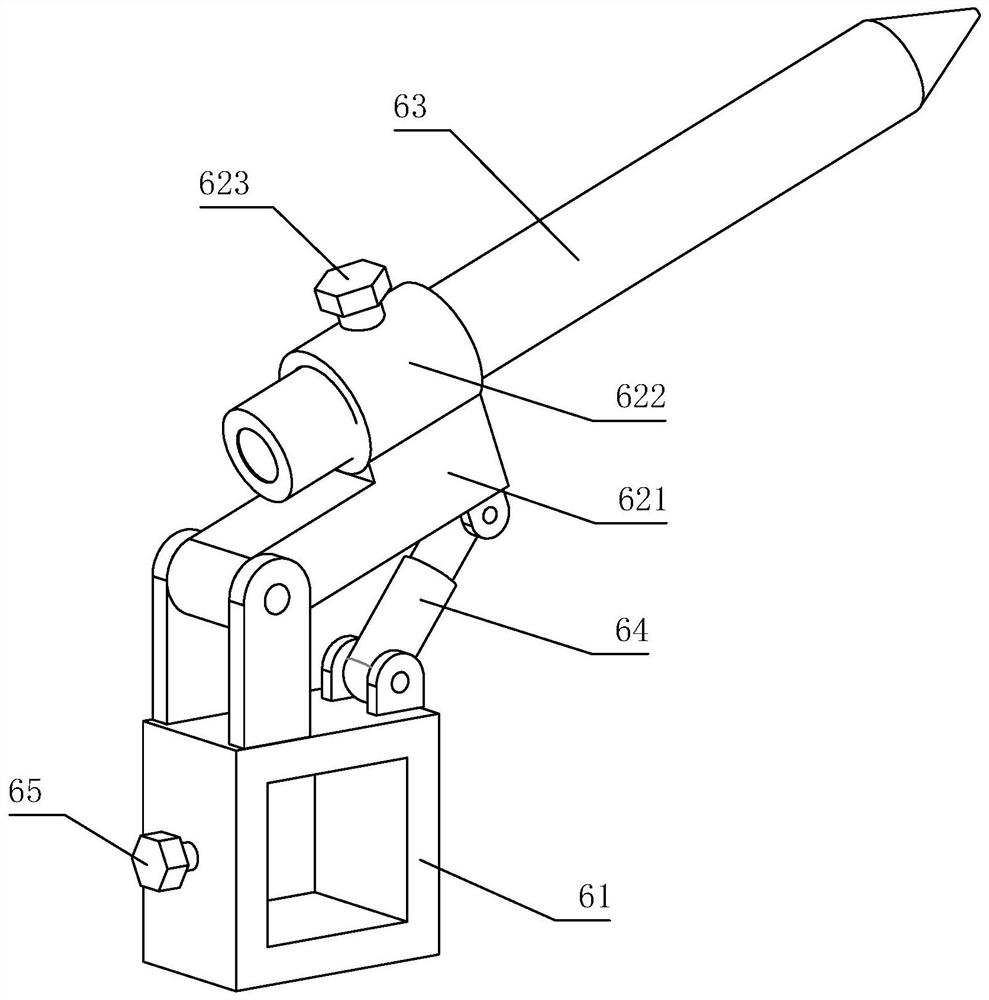

[0049] The embodiment of the present application discloses a wall surface automatic napping device, referring to figure 1 , including a rectangular horizontal guide rail frame 1, a sliding trolley 2 connected to the horizontal rail frame 1 along the length direction of the horizontal rail frame 1, a first drive mechanism 3 for driving the sliding trolley 2 to slide, a pair of hinged The guide rail column 4 on the sliding trolley 2 and parallel to the wall, the support beam 5 connected to the guide rail column 4 along the length direction of the guide rail column 4, the second drive mechanism 7 that drives the support beam 5 to slide, and is arranged on the support On the beam 5, a roughening mechanism 6 is used to roughen the wall surface in the form of high-pressure water jets. The sliding trolley 2 is provided with an adjusting member 9 for adjusting the inclination angle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com