Device capable of quickly detecting fixed pretension torque of anchor rod during installation

A bolt and pre-tightening technology, which is used in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problem that the pre-tightening torque of bolts cannot be accurately and quickly applied and detected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

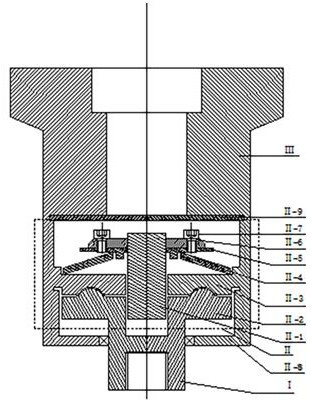

[0016] Embodiment 1 A device for rapid installation and detection of anchor pre-tightening torque, which mainly includes a connecting member I, a torque control unit II, and a torque output mechanism III; one end of the connecting member I is an internal thread structure for connecting the anchor rod For the drilling rig, the other end is a ferrule structure for connecting the torque control unit II; one end of the torque output mechanism III is connected with the torque control unit II through a ferrule, and the other end is an inner slot for connecting the bolt nut, directly connected to the bolt The nut is used for matching connection;

[0017] The torque control unit II adopts an upper and lower concave-convex chuck structure, which mainly includes a guide shaft Ⅱ-1, a convex lower chuck Ⅱ-2, a concave upper chuck Ⅱ-3, a precision disc spring Ⅱ-4, and a pressure plate Ⅱ-5 , Anti-return washer Ⅱ-6, torque adjusting nut Ⅱ-6; guide shaft Ⅱ-1 is in the middle of torque control un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com