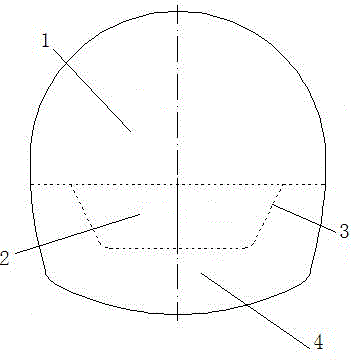

Construction deformation control method for lower step of high crustal stress weak surrounding rock tunnel

A technology of weak surrounding rock and high in-situ stress, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as damage, and achieve the effects of accelerating cycle time, fast overall construction progress, and reduced slag output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] 1) Construction preparation:

[0094] Monitor the state of the support and surrounding rock of the upper step, and determine the stable state of the surrounding rock by the convergence index. The so-called stability of the surrounding rock means that the deformation rate around the tunnel is less than the convergence index. After the surrounding rock is stable, the lower step construction will be carried out. The measures of adding anchor rods and spraying concrete are adopted to strengthen the support system of the upper step. When the convergence rate of the surrounding rock of the upper step is less than 0.2mm / day, the surrounding rock tends to be stable;

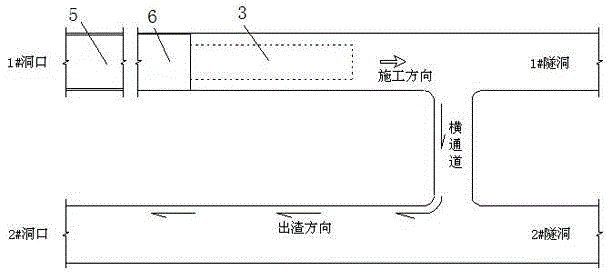

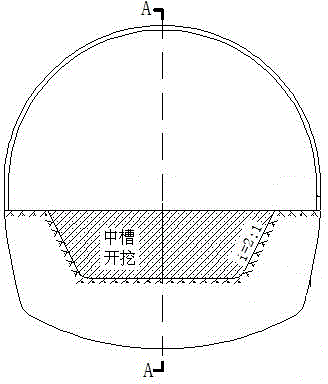

[0095] 2) Excavation of surrounding rock for lower steps:

[0096] The excavation height of the lower steps is 0.45 times the designed excavation height of the tunnel, the footage per cycle is 1.5m, and the amount of blasting agent used for a single blast reaches 200kg. It takes 45 hours to complete excavation, sl...

Embodiment 2

[0128] 1) Construction preparation:

[0129] Monitor the state of the support and surrounding rock of the upper step, and determine the stable state of the surrounding rock by the convergence index. The so-called stability of the surrounding rock means that the deformation rate around the tunnel is less than the convergence index. After the surrounding rock is stable, the lower step construction will be carried out. The measures of adding anchor rods and spraying concrete are adopted to strengthen the support system of the upper step. When the convergence rate of the surrounding rock of the upper step is less than 0.2mm / day, the surrounding rock tends to be stable;

[0130] 2) Excavation of surrounding rock for lower steps:

[0131] The excavation height of the lower bench is 0.5 times the designed excavation height of the tunnel, the footage per cycle is 2.5m, and the amount of blasting agent used for a single blast reaches 300kg. It takes 45 hours to complete excavation, sla...

Embodiment 3

[0163] 1) Construction preparation:

[0164] Monitor the state of the support and surrounding rock of the upper step, and determine the stable state of the surrounding rock by the convergence index. The so-called stability of the surrounding rock means that the deformation rate around the tunnel is less than the convergence index. After the surrounding rock is stable, the lower step construction will be carried out. The measures of adding anchor rods and spraying concrete are adopted to strengthen the support system of the upper step. When the convergence rate of the surrounding rock of the upper step is less than 0.2mm / day, the surrounding rock tends to be stable;

[0165] 2) Excavation of surrounding rock for lower steps:

[0166] The excavation height of the lower bench is 0.46 times the designed excavation height of the tunnel, the footage per cycle is 2m, and the amount of blasting agent used for a single blast reaches 250kg. It takes 48 hours to complete excavation, slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com