An integral linkage lifting installation method for electromechanical pipelines on the standard floor of a super high-rise building

An installation method and standard layer technology, applied in the direction of hoisting devices, lifting frames, mechanical equipment, etc., can solve problems such as the deformation of aisle unit modules, troublesome climbing operations, and reduced construction efficiency, so as to achieve increased support length, overall benefit, and improved The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] This installation method is applicable to the standard floors of all projects, especially for the large-scale standard floors of super high-rise projects with concentrated aisle electromechanical pipelines. The standard floors of residential building type projects can also be used, but it is recommended to use this technology for comparison of aisle electromechanical pipelines in project standard floors concentrated.

[0046] Before the prefabricated installation of branch pipelines, it is necessary to carry out on-site laying-out, and carry out prefabricated assembly of branch pipelines at the corresponding position vertically on the ground.

[0047] For the end points of DN25 pipes, artillery guns are used to prefabricate ground fixed-point prefabricated holes to install supports and hangers, which effectively saves the installation process of end points;

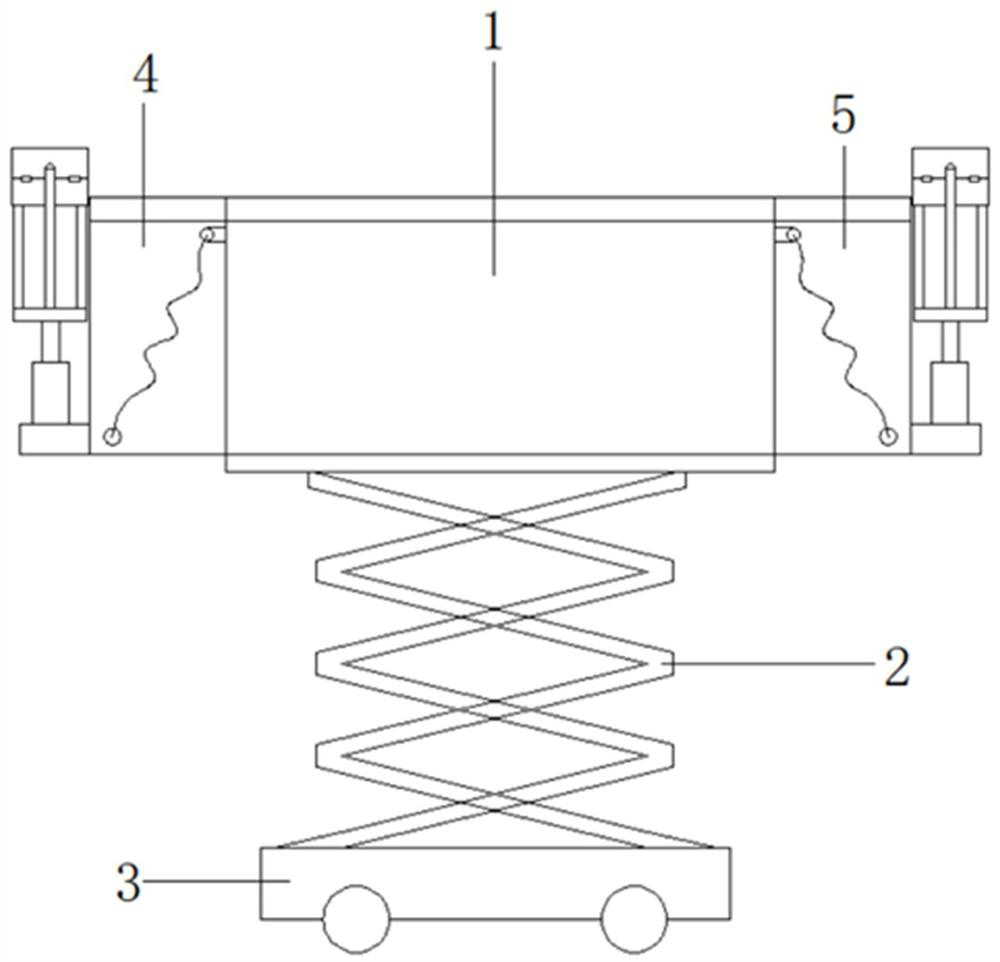

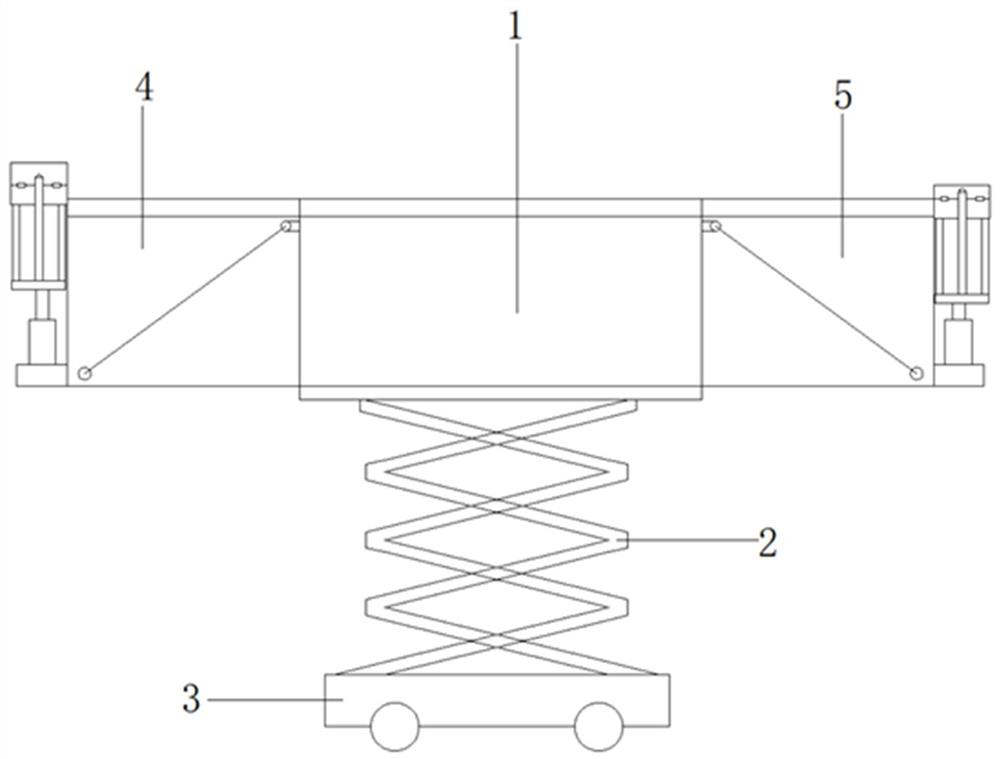

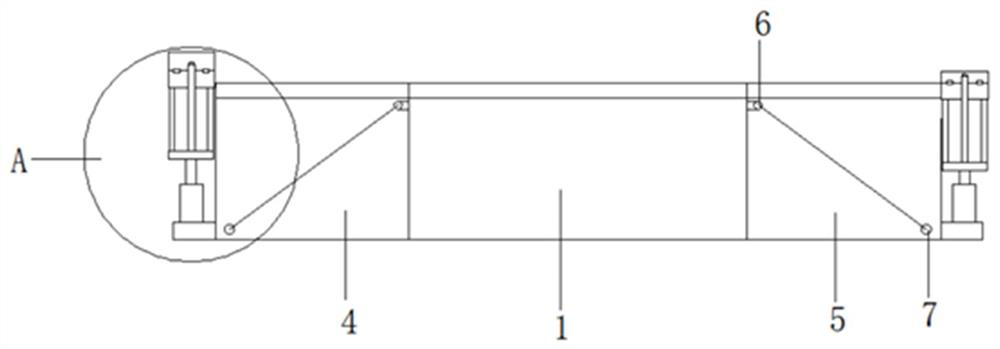

[0048] The aisle adopts the overall lifting installation method of the entire aisle unit module. It is necessary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com